I had the pleasure to visit Kings County Distillery for my Winery Assignment. It is located at 299 Sands Street, Brooklyn, New York, 11205 in the Brooklyn Navy Yard. This was my first time to a distillery and I wasn’t sure what to expect. I scheduled my tour for 5pm, so I had to leave early. I used google maps to navigate me to the location and was confused at first at the building I approached. The building was brick with vines growing on the sides of the wall. I read the sign that welcomed me into a bar, as I walked inside I immediately thought I was at the wrong location. I was at a bar. As I attempted to close the door and leave, a woman yelled out, “ are you here for the tour?”, I opened the door again and introduced myself. She confirmed my reservation and started to bombard me with questions about who I was and why I was here. I had to interrupt her mid-question and asked her for the bathroom, I had to go badly. She pointed the way and I walked down this very old, but surprisingly sturdy staircase. The bathroom was ancient and a little demonic, with five lit candles under a mirror. When I arrived back upstairs it was time to start the tour.

We walked to another building, and this was where the whisky was made and sold. Lisa, our guide, showed us the room first and then we followed her into a discussion room, where she talked about how whisky came about. She mentioned things about prohibition, speakeasies, the whisky wars. After the history lesson she took us back down stairs to explain how the whisky is actually made. She explained the products needed to make whisky. First you make a mesh, which is the grain you use and is the sugar needed to make whisky. The combination they used was 80% corn and 20% molten barely. The mesh is cooked to break down the sugar and then placed into a cannon to separate the liquid from the solids. Yeast is added and the liquid is heated with steam to extract the alcohol from the water. Alcohol Evaporates at a lower temperature than water does, so the temperature is very important at this stage. If it is too high, too much water will be in the end product. The vapor then passes through copper pipes to cool down and is collected into a tank. There is a process called spirit run where the alcohol that is produced is separated from non consumable to consumable. The liquid that comes out first is Methanol and it comes out blue from the contact with copper in the production process. Then the rest is Alcohol.

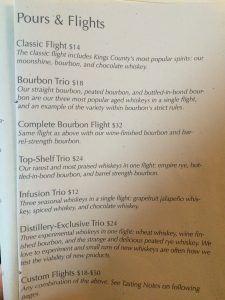

The tour ended with the group having a whisky tasting. I didn’t like anything I had and since it was so strong I left the establishment with a pounding headache. Other than that I enjoyed myself and felt like I learned a lot about the whisky production process.

“Kings County Distillery.” Kings County Distillery, http://kingscountydistillery.com/.

New York Distiller’s Guild. “NY Distilled.” New York Distiller’s Guild, https://www.nydistilled.com/.

https://gyazo.com/a9dc0b9a17d9d3a1922c73a221cb5e56 – Here is a picture of me at the brewery. Behind me is the line for the tours as well as large containers for the beer

https://gyazo.com/a9dc0b9a17d9d3a1922c73a221cb5e56 – Here is a picture of me at the brewery. Behind me is the line for the tours as well as large containers for the beer

https://gyazo.com/1a86eaff44fac1b5d52c20e3996c1782 – Our guide explained that the tubes above we sending ready to use malt into a container that would then send them across these tubes to be ready to heat and stop germination.

https://gyazo.com/1a86eaff44fac1b5d52c20e3996c1782 – Our guide explained that the tubes above we sending ready to use malt into a container that would then send them across these tubes to be ready to heat and stop germination. https://gyazo.com/e805d4f8d70826401c9408c77b14566c – Here is a look at their Bottling station. They claimed to be use modern techniques to help brew their beer, but the process of it all is still very traditional. They make sure that the original taste remain the same from bottling to the hands of the consumer.

https://gyazo.com/e805d4f8d70826401c9408c77b14566c – Here is a look at their Bottling station. They claimed to be use modern techniques to help brew their beer, but the process of it all is still very traditional. They make sure that the original taste remain the same from bottling to the hands of the consumer. https://gyazo.com/1186b298e1a6ae67d98724d56b17b58e – Here is something that I found very interesting. They use class bottles that they’ve used in the past as decoration throughout the main pub area.

https://gyazo.com/1186b298e1a6ae67d98724d56b17b58e – Here is something that I found very interesting. They use class bottles that they’ve used in the past as decoration throughout the main pub area. https://gyazo.com/596b45e367c5dbb9f04659fabd26bb5e – The last picture that I wanted to show is the room where the bottling actually happens. It’s a fairly large room and the reason I wanted to include this is to explain how they bottle. When bottling is about to conclude, they will drop a little hot water to make the liquid bubble. In doing so they make sure to cap it, so no oxygen escapes.

https://gyazo.com/596b45e367c5dbb9f04659fabd26bb5e – The last picture that I wanted to show is the room where the bottling actually happens. It’s a fairly large room and the reason I wanted to include this is to explain how they bottle. When bottling is about to conclude, they will drop a little hot water to make the liquid bubble. In doing so they make sure to cap it, so no oxygen escapes.