Assignment 09

DESCRIPTION

Refine your surface from Assignment 08 in RhinoCAM. Using your milled “blue foam” surface as a starting point, what changes/refinements would you make? In this assignment you will be milling your surface out of HDU foam (see material sample images below). How might this new material affect your design and toolpaths? Follow the videos provided below and use the Rhino template and CSV tool set file provided on the Course Files page.

REQUIREMENTS

Come to class on May 15st with your RhinoCAM file completed through the roughing and finish toolpaths and a completed toolpath study performed using the InDesign template provided on the Course Files page. Remember all HDU surfaces/toolpaths must be approved by Professor Ringley before you mill them.

Material example

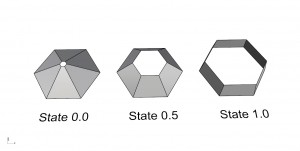

SAMPLE TOOLPATH STUDY

RhinoCAM Basic 3 Axis CNC Toolpathing Strategy

BONUS ROUND!

Do the Dip! If you are interested you can modify your surface to use the dipping milling techniques demonstrated by Professor Ringley last week. Video to follow, but please refer to the documents below.

An expanded CNC toolset for RhinoCAM which includes both the original cutters specified for your 3 axis assignment and the lolli cutters for patterning is now available on our course site:

Course Files

The direct link to is available here:

ARCH3590 SP13 Roland Toolset w-Lollis.csv

As always, verify tool overhang length when loading any tools into the spindle to avoid collision.