For this assignment students were asked to develop a previous pattern or a new idea, so that it can be milled via CNC. Then cast in concrete, silicon, or resin in order to create a cast that will be useful in an architectural application. The pattern that I chose is from my 3rd set of iterations: https://openlab.citytech.cuny.edu/kingarch4831designtobuild/fall-2016/kristian-2/k-iteration-3/

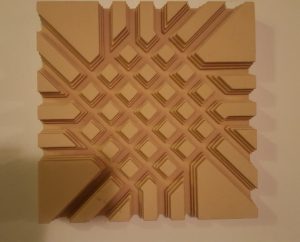

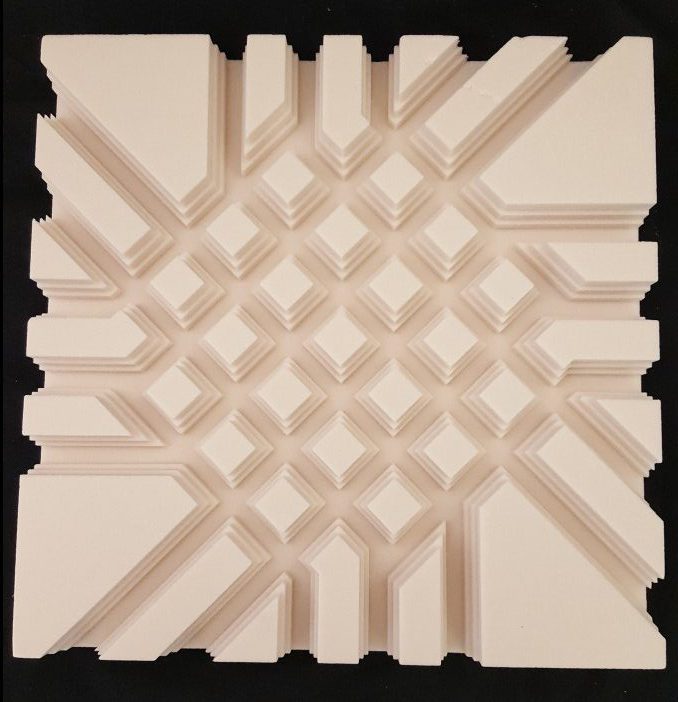

Milled patterned from Roland CNC Router ready to be coated and have concrete casted upon it. 20 mins.

After visiting the CNC mill room to cut out the negative molds and then applying an even amount coating of paste wax. I then proceeded to a local Home Depot then purchase material for the next part of the cast, which will be making a form for the mold .

One thing I purchased melamine board, which is used for shelving, but in this case it will be cut and used as a non-stick surface for my mold.