https://drive.google.com/drive/folders/0ByMWyEMe3MXNMzU1NlN6djVGVEE

K – Voorhees Hall Corridor Chair

As a follow-up project for the Design to Build class students were asked to think of some design strategies to better improve the corridor space for Voorhees Hall 8th floor. As a class we thought of display space and presentation space improvements, areas for seating, areas for eating, and social areas to engage students with one another.

As a team Henry, Asli and I thought of a few things to greatly change the look of the 9th floor. One design that I found interesting and worked with Henry to make it a reality was the thought of a multipurpose chair or seat for the students and architectural studies staff.

Here’s a link to Henry’s page which shows his part in the development of the chair iteration: https://openlab.citytech.cuny.edu/kingarch4831designtobuild/fall-2016/henry/h-voorhees-hall-iteration-5-chair/

The chair iteration was to be multipurose with a pivoting backrest for comfortability in mind. that backrest would then fold on its pivot in order to configure itself as either a chair, stool, table or display for the students and professors.

From that rendering and with the help of Rhino and CNC milling, Henry and I worked together to have a model that expressed our ideas.

When planning to create something from scratch things like cost, time, and assembly matter most.

https://youtu.be/El8BDTZLzJs

Before and after of the chairs backrest. Left shows a finished part from the mill that has been sanded, the right is a milled part unsanded.

The final result…

Chair Iteration Completed!

What’s next…

An improvement on the design of the chair so that it is more affordable, easier to fabricate and assemble. We are also exploring the idea of making this chair wall mounted to accommodate more space for students and teachers alike. Also the presentation boards, they will have storage designs that will tie into the chair design so that seating and presentation are not the only two uses.

SS – Iteration 5

I used one of my pattern molds to cast the negative. Once I pour the plaster into the mold, I had to wait 30 minutes in order to remove the mold and then I let it dry for 24 hours. While removing the mold you have to be careful because the plaster still not as strong and it might break.

+

+

=

Please take the following survey

The department is looking to make modifications to the first two years of our program (AAS) and we would like to get your input. Please take this ASAP and forward it to any friends in any of your other classes. Your opinion is very important.

Thanks – Professor King

MIXING CONCRETE

Concrete Competition

2016-2017 Concrete Competition

The following is an alternative to the hallway design to complete a cast for the semester. Please remember that casting a piece (any material, concrete, plaster, epoxy, etc.) is a requirement for this course and will factor into your grade.

Iteration 1

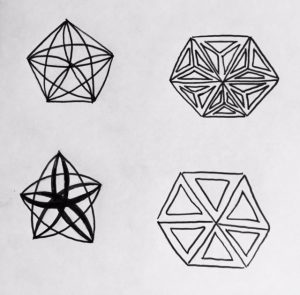

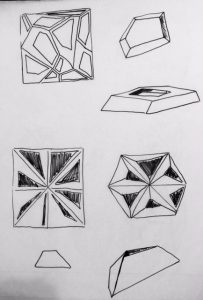

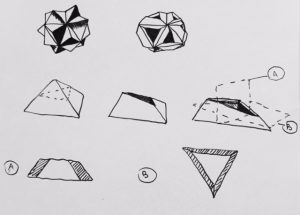

1. Developing the iteration of similar repeatable pattern:

Work with sketches then Rhino software:

Time: 3 hr

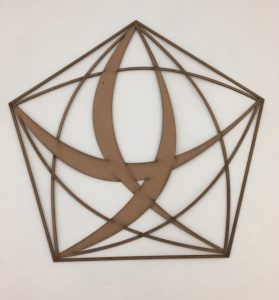

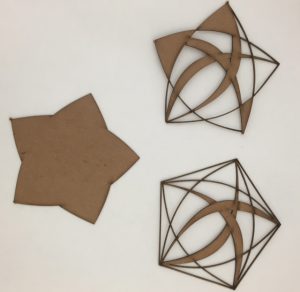

2. Cutting patterns using laser cutter and developing iterations of each at different scales:

Materials: cheap board 22 x 14 inch and Bristol paper 14 x 17 inch

Scales: from 2 1/2 inch to 11 inch

Time: 2 hr

3. Assemble patterns into 3D dimensional objects:

Time: 2 hr

Requests for Material/ Contact over next two weeks

All,

If you have any requests for material to mill in the CNC lab, please let me know so that the material is ready for you guys to use. Also feel free to contact me via email for any questions you have regarding the casting process.

TFuger@citytech.cuny.edu