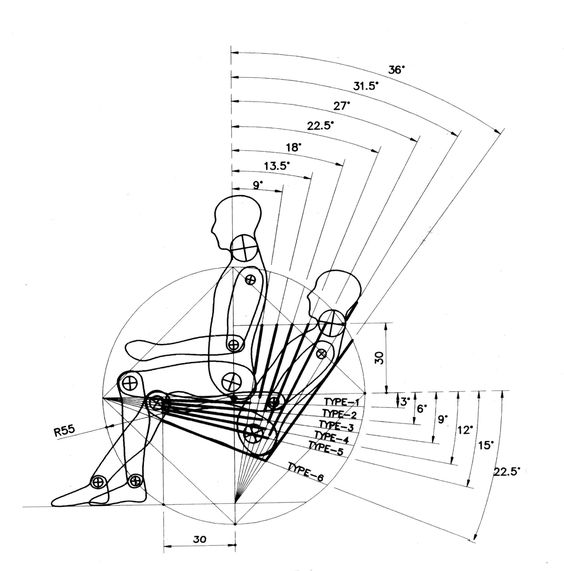

I decided to go in dept with the chair first and see if I could actually physically build it. I first started researching chair angle details and diagrams. The diagram below was taken from www.disenodelmueble.com. I deiced to give the seat a 3 degree pitch with a 13.5 degree back rest pitch. I did not want to give a large pitch because the chair is small at 16x16x16in and may tip over if someone were to lean on the backrest, it may tip over.

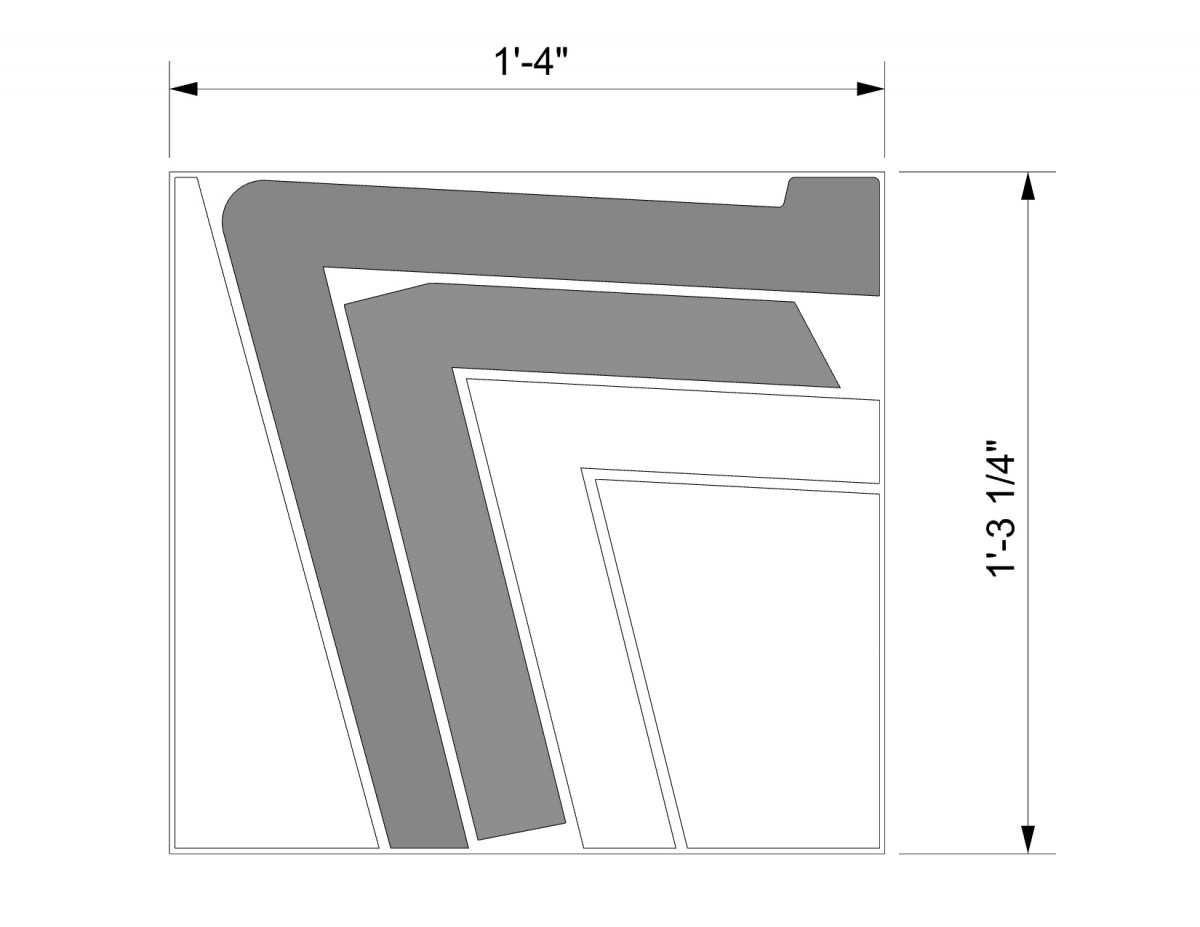

I narrowed down many design options and finally came up with an iteration that could be made. I changed the original cut line diagram with one that would work better with the pitch. The gray pieces are the one i will use on the chair. Notice that some extra angled cuts were made. That is because I need both pieces to attach better.

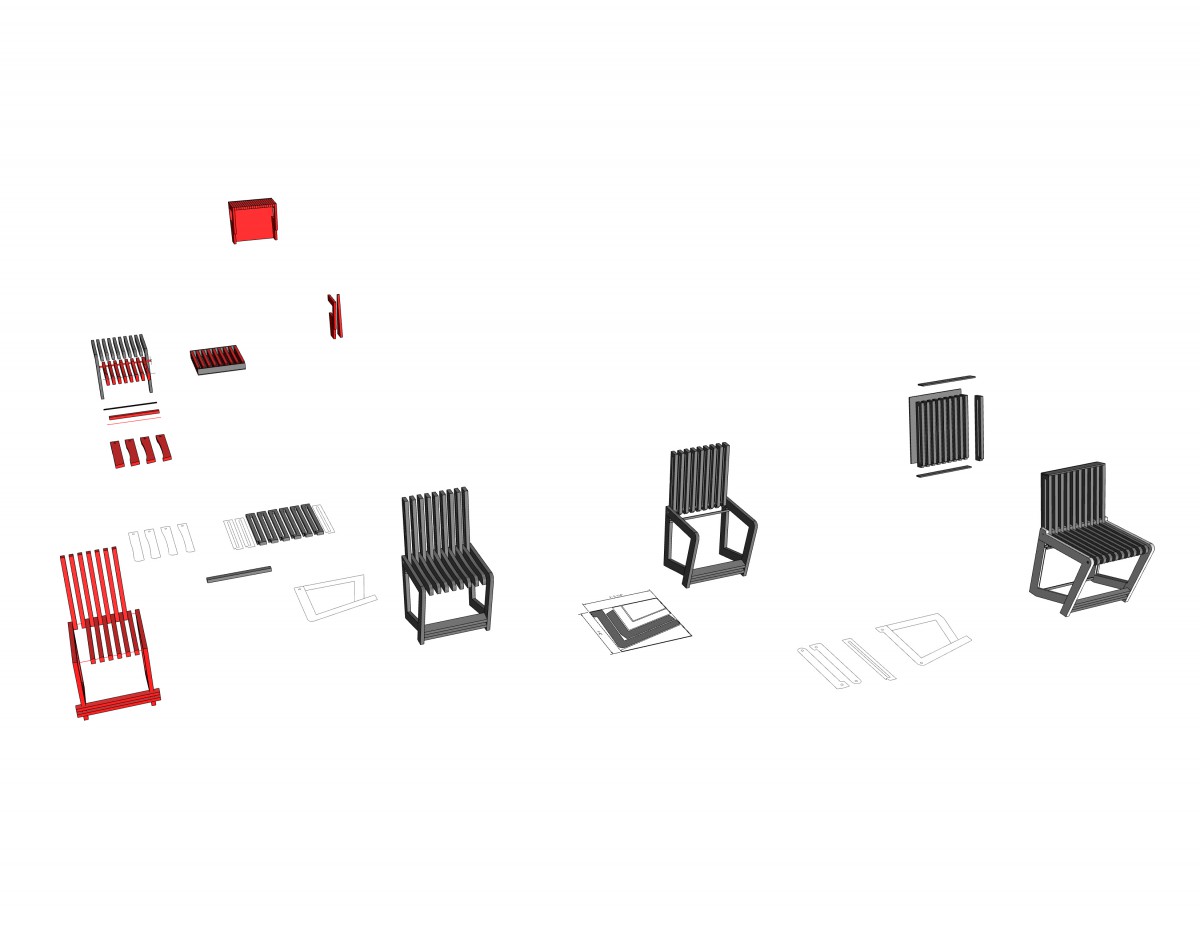

Then I started 3D Modeling the chair even further with more detail. I spaced out every piece a little over 3/4″ apart. It needs some wiggle room just in case to the movable portion does not get stuck.

This is the portion that took the most time. I made about 10 iterations of the chair with very slight changes to the angle, size, thickness, and connections.

After, I found the best version of the chair that fit all of my required dimensions. I also managed to incorporate students pattern iterations onto the chair.

The following image show a step by step process of how i will attempt to build the chair.

1st: I will cut the frame of the chair. There are two pieces to each side of the chair.

2nd: I will figure out were to place all of the metal which will hold the seat and backrest of the chair.

3rd: I will assemble the seat using the metal rods and space them out evenly. They are space about 0.77 in apart. slighter bigger than the thickness of the wood material.

4th: I will add bracing on the bottom of the chair for both support and it will also act as a foot rest.

5th: Assembly of the backrest component. Each layer of wood will be supported from 3 sides; the top, the bottom and the back. I cannot put any rods through these pieces because it will have to rotate and it cannot collide with the seat. The backrest is designed to fold over the seat to become a model display area.

6th: I will assemble the entire chair together.

7th: Install the student pattern iteration. I’ve made sockets on the inside of the chair. the sockets provide a space for any material less then 3/8″ thick. This way we can incorporate students patterns into the chairs and it will also make every chair look unique.

This step is optional if it does not look good.

The image bellow is a rendering of what the chair should look like in all of its positions. I am very happy with the outcome. The chair looks great and it is definitely multi functional.

Image with patterns.

Total time EST: 8 hours