This week I spent most of my time on casting concrete for my chair design.

After last weeks failed attempt at casting (concrete hardened too quick) I took extra precautions to make this attempt more successful.

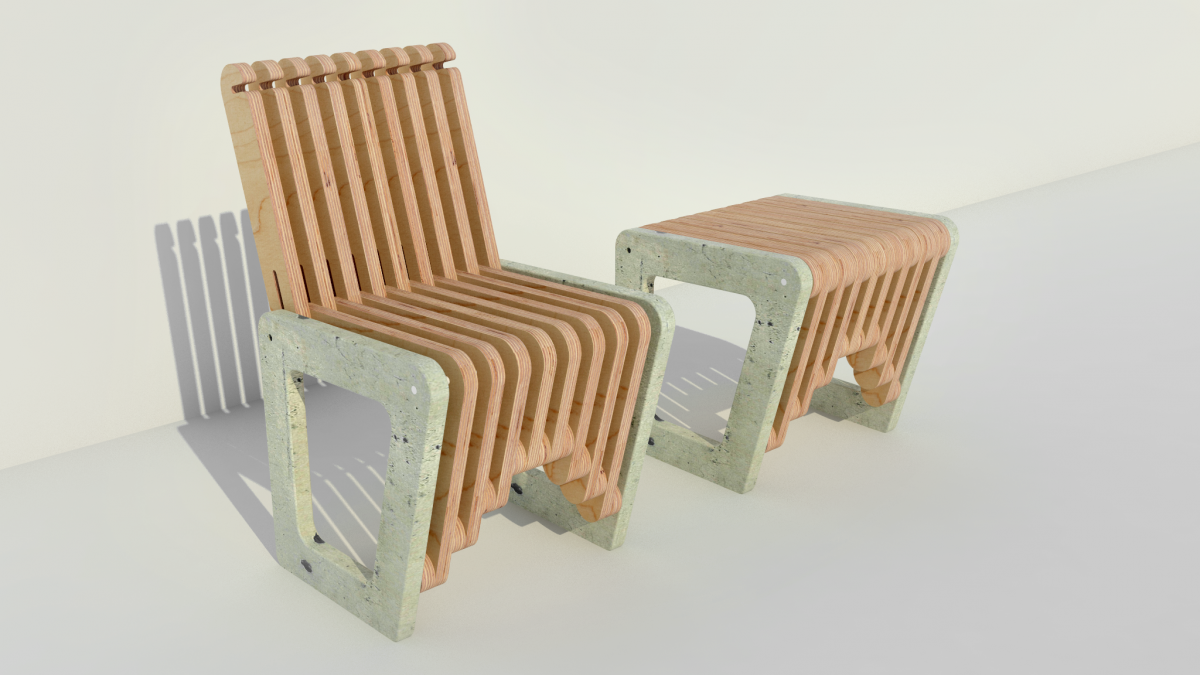

I finished modeling the chair v2 on rhino to get an accurate understanding of what I am attempting to accomplish.

This chair design is much sleeker than the previous. It is also much more sturdier if the concrete comes out correct of course.

I choose to focus on the concrete cast. Base off of my last chair design v1, CNC milling the wood pieces was successful so I should not have a problem making the new wood pieces.

I started with 2 concrete molds made of foam. Each piece of foam was milled with tapered edges so that the concrete does not attach to the mold.

Then I applied vegetable oil to the mold to act as a release agent. I did not have paste wax on hand so I took a risk and tried to oil, knowing that it may not work.

I then places stopper nuts on the correct position so that the 3/8″ threaded rod would fit exactly in place when the time came. The nut will be secured into the concrete making a better bond.

I then strained the concrete to get rid of the larger aggregates. Since my mold is only 1.25″ thick, I cannot have large aggregates because the concrete will not be able to settle correctly.

I substituted the large aggregates with fiber glass strands. In theory the stands will provide tensile strength to the concrete and make it a lot more stronger.

I poured the concrete into the mold. Taping and shaking the mold so that the concrete would settle correctly.

I then took the concrete out of the mold. The vegetable oil worked!! I will be able to use the mold again.

The second cast was not successful. The piece cracked when I attempted to take it out. Maybe the concrete was not cured enough. After all I only waited about 48h.

I will able to use the molds again so this time I will wait longer for the cure. One piece will be useful for the final prototype.

Next step is to CNC the wood pieces and start assembly.