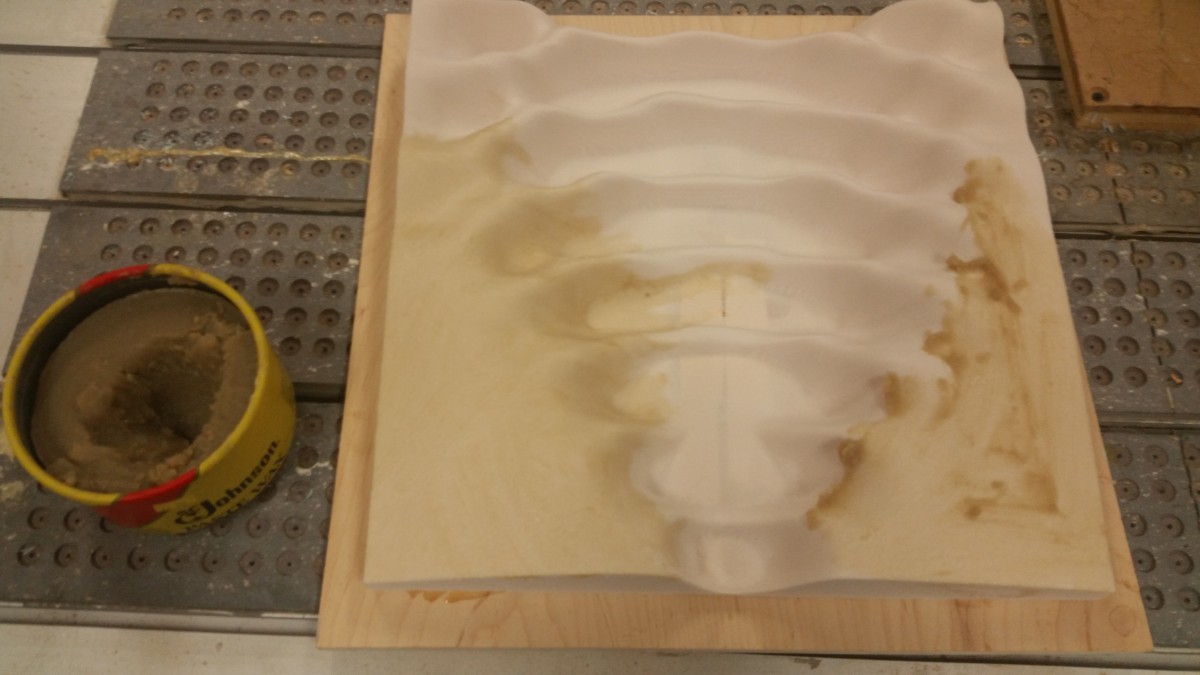

I first started with a negative mold which was designed on rhino can milled on the cnc machine. I made sure that the mold had somewhat tapered corners so that the extraction process would work properly. I also gave the mold a coat of Johns paste wax which acts as a releace agent.

Next I built a frame all around the mold which will act as a boundry box for the concrete pour. The height of this box will determine the thickness of the case. I also applied more johns paste wax to the frame and screwed everything together tight.

After I poured the concrete into the mold. I made sure the mold was leveled. I also made sure that the concrete was spread evenly and vibrated the material so that concrete would seep into every valley.

After I poured the concrete into the mold. I made sure the mold was leveled. I also made sure that the concrete was spread evenly and vibrated the material so that concrete would seep into every valley.

After 3 days, I removed the frame. The concrete was still a little brittle so I had to handle it very carefully.

Then I removed the concrete from the mold. It was an easy task due to using the release agent.

The mold was re-useable, so I made another cast for addition practice. I placed to two pieces of concrete next to each other and placed a piece of glass over it so that the glass would act as the top sufrace. This piece can become a table, stand or shelf.