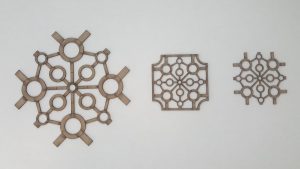

CNC MACHINE

AFTER FINALIZING THE PROCESS OF MY CONCLUSIVE PATTERNS, I CHOSE THE ONE I FOUND TO BE THE MOST INTERESTING ONE AND TOOK IT TO THE CNC ROOM TO START A NEW PROCESS.

STEP #1

FINAL PATTERN DESIGN

STEP #2

APPLIED ALL NECESSARY CHANGES FOR THE PATTERN TO BE CUT IN THE CNC MACHINE IN RHINO (WITH HENRY’S HELP. THANKS HENRY!!)

STEP #3

SELECTED THE EQUIPMENT NEEDED FOR THE CNC MACHINE TO DO THE CORRECT CUTTING ON A 2″ THICK FOAM

STEP #4

AFTER EVERYTHING WAS SET UP THE CUTTING PROCESS INITIATED

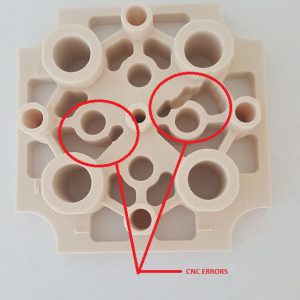

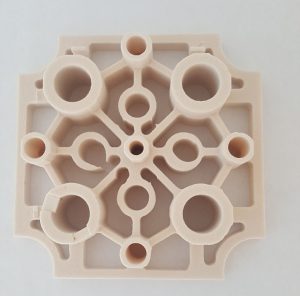

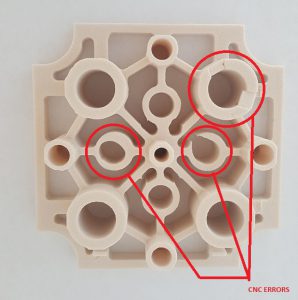

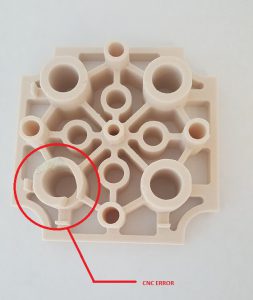

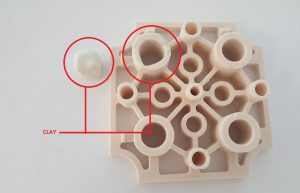

FINAL FOAM MODELS

DO TO THE MOVEMENT OF THE FOAM DURING THE CUTTING PROCESS THERE WERE ERRORS IN ALL 4 MODELS

MODEL #1

MODEL #2

MODEL #3

I ATTEMPTED TO COVER THE ERROR WITH CLAY IN MODEL #3

FOR THE 4th MODEL I ATTEMPTED TO DO A SILICON MOLD