The topics discussed in our third class meeting included:

- Knot of the day

- Homework #1 notes/common mistakes/questions

- Homework #2 questions

- Mechanical advantage

- Block and fold system lab

- Block and fold system lab calculations

1. First off, knot of the day!

Figure 8 knot.

This knot is perfect for preventing the end of a rope from slipping through a hole or pulley.

Link to figure 8 knot how to:

http://www.animatedknots.com/fig8_/#ScrollPoint

Link to figure 8 knot followthrough how to:

http://www.animatedknots.com/fig8follow/#ScrollPoint

2. Homework #1 notes/common mistakes/questions

Notes from McCollough concerning HW #1

-Units! Pay attention to units and make sure to label all units.

-Check your work.

-Don’t ignore distributed loads (References: Stage Rigging Handbook pg.5-12 and pg.10)

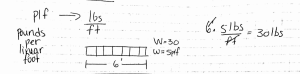

As for questions concerning HW #1 we reviewed/discussed distributed loads. Below is a picture of the example used in class:

3. Homework #2 questions:

-Pertaining to question #7 on HW#2 we went over allowable tensile load

P all= Ft*A

-Pertaining to question #6 on HW#2 we went over area of a circle (in regards to the material used)

Area of a circle = πr²

4. Mechanical Advantage (a.k.a the ability to lift heavy objects without exerting all the force on your own!)

“Mechanical advantage is the ratio, or comparison, between the force required to move a load and the force of the load.” (Stage Rigging Handbook 3rd edition pp. 49)

Mechanical Advantage incorporates the following elements:

-ratio of effort put in vs. effort put out

-the load

-friction force – proportional to what the load is

Trivia

Question: Does a single pulley create mechanical advantage?

Answer: No, due to friction. A single pulley can only change the direction of a rope.

Friction

When referring to Table 2.1 (Stage Rigging Handbook 3rd edition pg. 52) we can see that when adding 1 to 10 lines/rope, the mechanical advantage increases as the load remains the governing factor.

When adding anywhere between 10 to 15 lines/rope mechanical advantage decreases as friction becomes the governing factor.

……………………………………………………………..

TMA – Theoretical Mechanical Advantage

AMA – Actual Mechanical Advantage

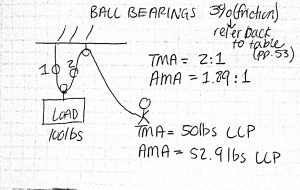

Below is some work that we did in class pertaining to TMA and AMA.

Trivia

Bronze has a low coefficient of friction. Materials with low coefficient of friction are more expensive!

We can calculate:

–LLP (Lead Line Pull) – Required to lift a load

–Lines required to lift a load with LLP

–MAX load for given system

We do all the above calculations in order to:

-Know what you need for your mechanical advantage system

–Know if we have the man/woman power needed to supply the required force

–Figure out the type and strength of rope needed for your system

Knowing the LLP limit supplies us with:

–the amount of people needed and WLL (Working Load Limit) of rope

Knowing the MAX load supplies us with:

– the fixed LLP (Lead Line Pull)/ the x amount of pounds that can be lifted

……………………………………………………………..

Formulas

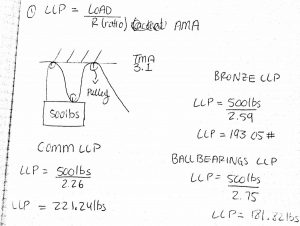

LLP= LOAD/R (ratio)

-Ratio in the above and below formulas pertain to the AMA found on the appropriate table (2.1-2.4) in pages 52-54 in the Stage Rigging Handbook 3rd edition.

Below is a sample problem completed in class.

When trying to decide how many people you need to lift a load you must consider the following:

-situation, use judgement

-is lifting the load the first or last thing scheduled in a 16 hour day?

-fatigue, etc.

-average is 50lb per person

Lines required to lift a load w/LLP

LOAD/LLP=AMA min

ex: 1,000lbs/250lbs=4

Note: LLP can be the WLL of the rope or force you apply

Maximum load, given system

MAX LOAD=LLP*AMA

5. Block and fold system lab

For lab this week we headed downstairs into the scene shop were we worked with the I-beam, rope, 2 pulleys, a green cart, a genie, 170 pounds of sandbags, crocheting, and a lot of hands.

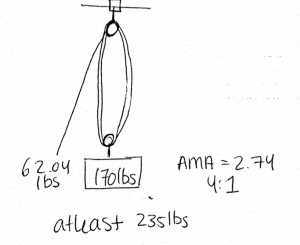

First we calculated the TMA (Theoretical Mechanical Advantage) of our system. System uses plain bearings with 10% friction.

Drawing of pulley system used for lab

TMA= 4:1

We then attached a green cart to the block closest to the floor (lower block), we quickly noticed that there was a lot more pulling of rope involved than there was increased height of the load.

Next, we retrieved 170 pounds of sandbags and attached them all to the block on the floor. The line pull (rope) measured 5/8″ diameter so it was easy for the volunteers to grab onto and pull comfortably.

After completing the lifting of the load demonstration we proceeded to learn the proper handling and care that must be taken when striking a block and fold system.

When striking a block and fold system you must:

- You need 2 people. Each person grabs a block (person who grabs the floor/lower block must hold on to the end of all the extra rope to prevent an unwanted knot to occur) and pull away from each other.

- Continue to pull away from each other until all rope is straight and all rope has been feed through the blocks.

- Lay it down on the floor, and crochet! Making a loop closes to the lower block to start and feeding the rope in the same direction (to prevent any unwanted knots) until you reach the other block.

- Properly store the system.

Note: I know this may be hard to understand, I was unable to get a picture of the final product but it lives right my McCullough’s office if you want to take a closer look.

After the lab, we went back upstairs into the classroom and performed some calculations.

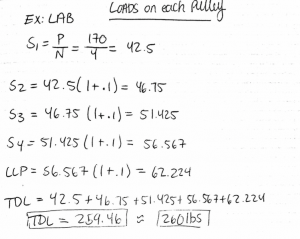

6. Block and fold system lab calculations

Loads on each pulley, where:

F=friction, P=total load, N=number of ropes, S₁=furthest one away from lead line, and S=sections/parts of rope, LLP=Lead Line Pull, TDL=Total Distributed Load

S₁=P/N

S₂=S₁* (1+F)

S₃=S₂* (1+F)

S₄=S₃* (1+F)

LLP= S₄* (1+F)

TDL=S₁+S₂+S₃+S₄+LLP

Note: You can continue to add more sections, as long as you follow the above samples ex: S₅=S₄* (1+F) , S₆=S₅* (1+F), etc. Follow through with TDL formula.

Below are my calculations for the lab pulley system used.

Hope this brings a little more clarity to you if you were having some problems.

Feel free to shoot me a question through here or in person.

– Yarie