Hello Everyone,

You all know that English is not my strength, so I apologize in advance if my notes are a little bit confusing. However, I will do my best though, do not worry.

Let’s start by the new knot we learned.

The Lark’s Heat or the Lanyard Hitch:

Note: I used an app called 3D Knot and it is pretty useful, check it out.

This hitch is commonly used in theater to connect a short section tie line to the ring of a curtain.

Pros: The two ends of the tie line will be the same length.

Cons: The hitch can loosen itself to easily

Solution to cons: loosen the hitch/twist it 180º/ grad the ends/ go through again. The hitch will be locked in place. You can even drop a little bit of white glue to avoid the tie line robbers to steal them.

Lesson of the day is about HEMP RIGGING

This is a sketch of a hemp rigging system

This is a sketch of a hemp rigging system

The hemp rigging system is a system that which uses rope for the lift lines to the pipe batten. It is the bas of all the other rigging system. When using natural fiber, manila is the most common, but synthetic rope are usually used in modern theater.

The batten we used are 1.5″ Schedule 40 pipe (but round shape are bad are carrying load).

Loft Blocks can be underhung or overhung.

Head Blocks can have more than one rope going through.

With this system, stagehands carry all the load, but it can be balanced with sandbags up to 50 or 100 pound under the load.

The person who operates the system was call the Flyman.

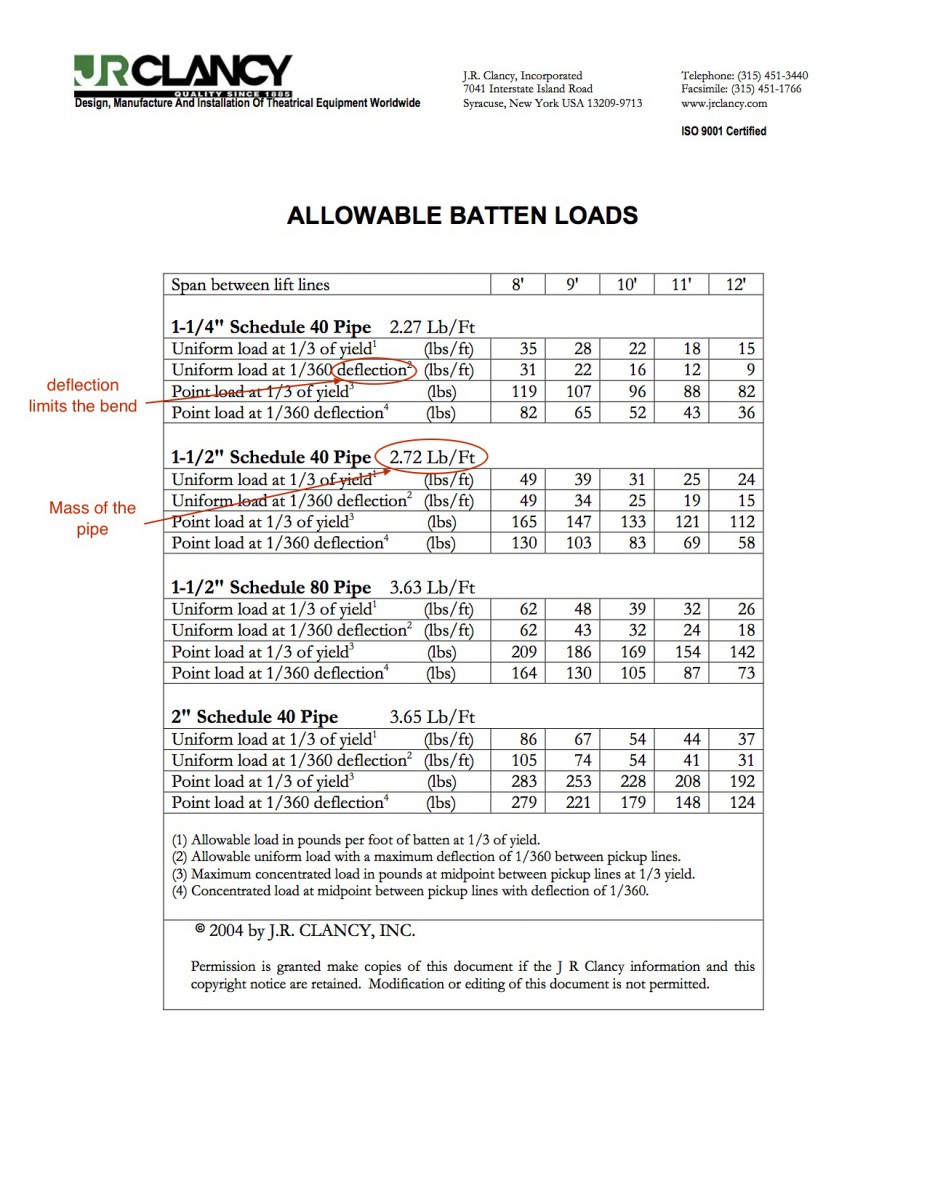

The allowable batten loads is the amount of load allowed on a batten (logic, but important to mention).

Below is a helpful chart for allowable batten loads:

To calculate the total load, here is the formula:

TOTAL LOAD = ALLOWABLE LOAD x LENGTH + PIPE

ROPE

Design factor

When working with fiber ropes, you want to use a 10:1 design factor.

Reasons Why using 10:1 DF:

- More susceptible to damage

- Strength is variable all the way through

When a knot is made, it reduces the efficiency of the rope by 50%, so anytime you work with a rope and a knot, a design factor of 20:1 has to be applied.

10:1 (using rope) + Knot (-50%) = 20:1 DF

Warning: Always find the rope specs before working in a new venue.

Advantage and disadvantage of three-Strand twisted rope

Pros:

- Shock absorption

- Cheap

Cons:

- Length changes with load

- Any damages affect the entire structure of the rope

Advantage and disadvantage of parallel-core rope

Pros:

- Very Strong

Cons:

- The inside can slip out

Loads

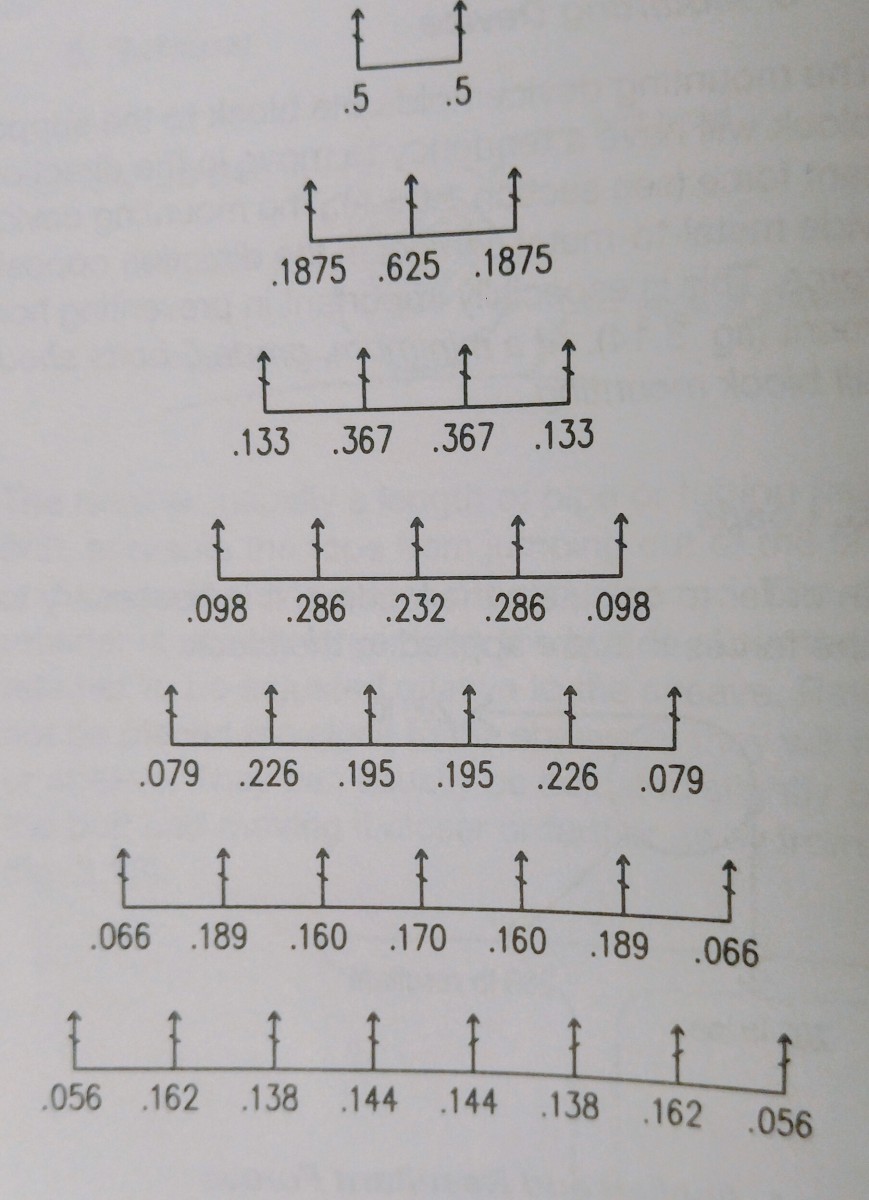

For a heavenly spaced line, the load on the ropes are different on different points.

Formula for choosing the adequate rope :

UBS = Load x DF

ex:

- DF of 20:1

- Load 425 lbs

UBS = 425# x 20 = 8500 lbs

You could use a 1″ Manila twisted.

When choose a rope, go with Manila, Nylon, or Polyester (Best).

Note: Polypropylene floats.

Anytime a rope is bent, you have a resultant load. The factor depend on the angle (1.41 for 90º)

Ex: 425 lbs x 1.41 (for 90º) = Resultant 600 lbs.

Sand Bags

When balancing the hemp system with sand bags, attach them progressively to not have to carry the entire load at once.

Pin Rail

Pin rails need to be strong enough to stay on the floor.

Manage your ropes

- Inspect periodically your rope for any sign of damage.

- When using your system, look, smell, listen for anything different than usual

- Every year, check all components of your rigging system (anything found, take the part away and replace it)

- create a log

Notes: the best height for a rigging system is 2.5 time the proscenium height.

Max