Hello Everyone,

I would like to take the opportunity to thank everyone for his or her help on October 31, 2019 for the Candies and Bonbon class of chocolate bark. We produced all the chocolate barks successfully. I would like to also Thank Michelle Mai who was our Steward for making sure we had all the ingredients before we started our production. Here is the recap of a wonderful day.

Chef Diane’s demonstration of Lemon curd

Double boiling method

Slowly stirring the mixture

Whipping butter to get the finish product

Tempering Chocolate: Demo by Professor Hoffman

Mixing and melting chocolate before tempering

Demonstrating the tabling method

Final Product by Professor Hoffman

Tempering chocolate using tabling method on the marble table

Paper used for testing the chocolate

Milk Chocolate

Milk Chocolate temperature 82°F – 86°F (28°C – 30°C)

Tempering milk chocolate

Spicy Milk Chocolate Bark with Cherries

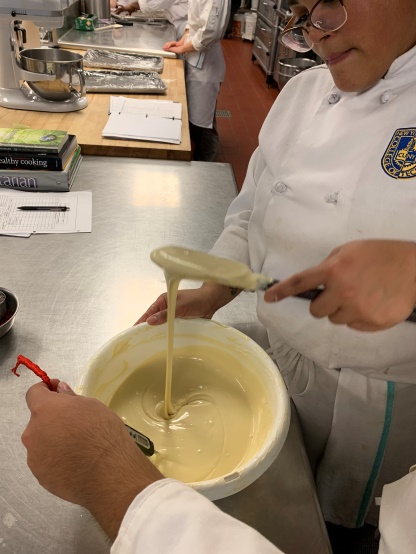

Mixing the tempered chocolate

Spreading cherries & chili powder

Final Product

Dark Chocolate

Dark Chocolate temperature 84°F – 89°F (29°C – 32°C)

Tempering dark chocolate

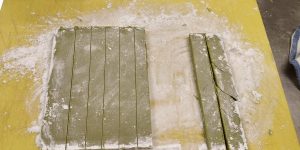

Dark Chocolate Ginger Bark

Mixing the tempered chocolate

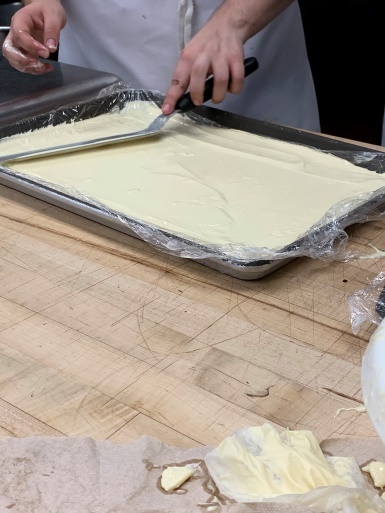

Acetate Sheet with plastic wrap used to spread chocolate

Tapping the sheet tray to remove bubbles

Final Product

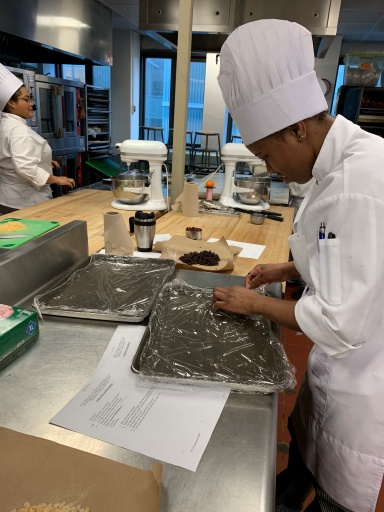

Chocolate Crispy Rice & Fruit Bark

Plastic Wrap used to spread chocolate

Mixing in the rice krispies

Spreading the chocolate on the sheet pan

Final Product

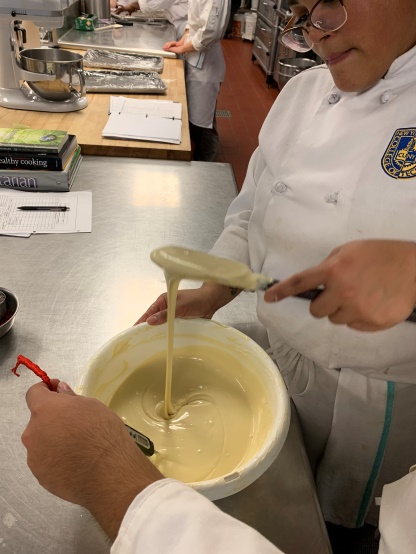

White Chocolate

White Chocolate temperature 79°F – 82°F (26°C – 28°C)

Tempering white chocolate

Due to the weather, the white chocolate took a very long time to get to the correct temperature. Different areas of the kitchen was used to get the chocolate to the correct temperature

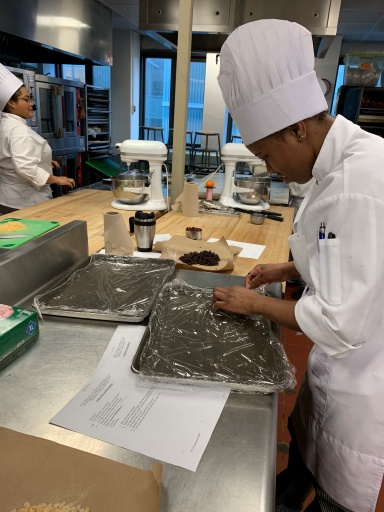

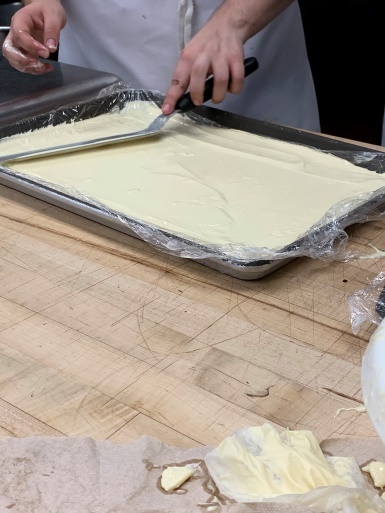

White Chocolate Cranberry & Pistachio Bark Production

Pistachios to add to the final product

Melting chocolate in the microwave before tabling

Spreading the white chocolate

Final Product

Display of final barks

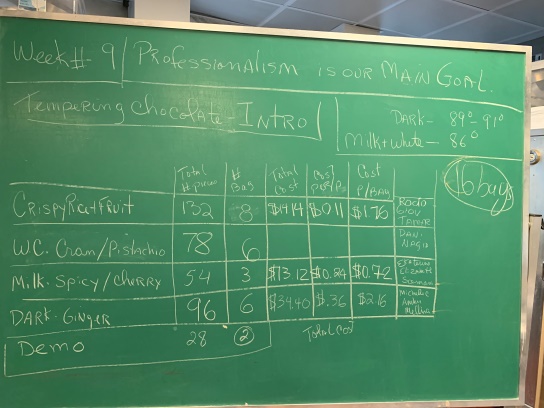

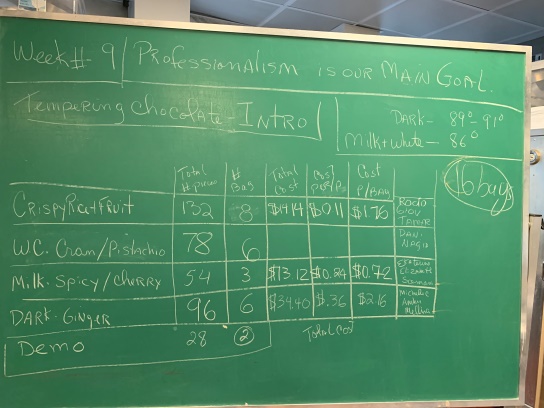

Costing of the product by each team

Candid Shots

Everyone enjoying tempering chocolate

Cleaning the marble table

Some helping with packaging

Some helping with the boxes

Not forgetting cleaning

Washing and sanitizing

Michelle the steward costing out the items for us

Professor Hoffman helping us to finish our late day

Hope everyone enjoyed the day and photographs.

These are candied grapefruit rinds, they were reduced in simple syrup and left to soak for two week prior to today. They were then removed from the syrup and left to dry out. After which they were tossed in sugar and then dipped in dark chocolate.

These are candied grapefruit rinds, they were reduced in simple syrup and left to soak for two week prior to today. They were then removed from the syrup and left to dry out. After which they were tossed in sugar and then dipped in dark chocolate.

Some of the rinds after they were tossed in sugar and they dipped in chocolate. They were then left so that the chocolate could harden or set up and be ready to be boxed up.

Some of the rinds after they were tossed in sugar and they dipped in chocolate. They were then left so that the chocolate could harden or set up and be ready to be boxed up.

These are candied pineapples they were also reduced in simple syrup. They were left over the same two week period to soak. Then they were removed left to air dry, tossed in sugar and dipped in dark chocolate.

These are candied pineapples they were also reduced in simple syrup. They were left over the same two week period to soak. Then they were removed left to air dry, tossed in sugar and dipped in dark chocolate.  The candied pineapples after they were tossed in sugar an then dipped in dark chocolate then the were left to harden and set up.

The candied pineapples after they were tossed in sugar an then dipped in dark chocolate then the were left to harden and set up.  A student from the class tempering the milk chocolate using the tabling method.

A student from the class tempering the milk chocolate using the tabling method.

Milk chocolate mendiantes piped using a cornet after the chocolate was tempered. Then they were topped with cranberries, coffee grinds, pistachios and chocolate curls.

Milk chocolate mendiantes piped using a cornet after the chocolate was tempered. Then they were topped with cranberries, coffee grinds, pistachios and chocolate curls.

A student tempering the dark chocolate stirring it constantly to ensure that it reaches the correct temperature in order to be used for dipping the fruits and piping the mendiantes.

A student tempering the dark chocolate stirring it constantly to ensure that it reaches the correct temperature in order to be used for dipping the fruits and piping the mendiantes.