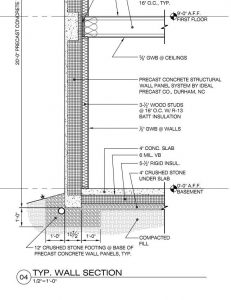

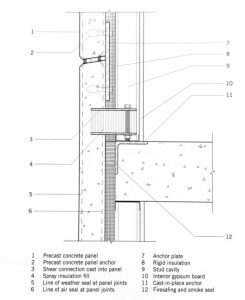

From interior to exterior a precast concrete wall begins with a group of layers consisting of a ½” of gypsum wall board, a 2×4 stud wall and 2” of rigid insulation for thermal protection. This connects to a precast concrete panel through an anchor plate, bolted into the precast panel. At this point of connection two precast panels meet with backer rod and inner sealant and outer sealant for waterproofing. A concrete slab connects to precast panel by a two layers of shear connection cast into the precast panel filled with spray insulation fill. This anchored into the slab and shelf angle on the corner of the slab. Between the shelf angle and precast panel is a space for the fire safing and smoke seal to protect against fires.

CaseStudyGrid_Yocelyne_Portillo_Final_8.03