Tom:

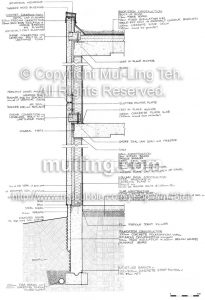

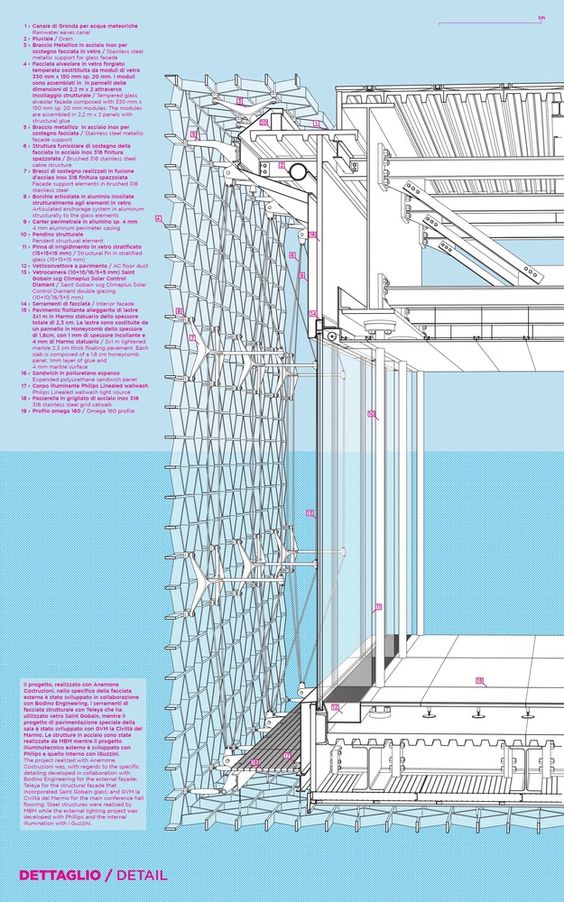

- (Image Wall) Perforated Stainless Steel Rainscreen

- Stick Glass Curtain Wall system

Yocelyne:

- Metal Panel Wall

- Concrete Wall

Chandanie:

- Anodized aluminum wall

- Brick veneer wall

Tom:

Yocelyne:

Chandanie:

WALL PANEL: A non-structural element that forms a curtain wall with loads transferred from the wall panel to a structural frame.

WALL PANEL ADVANTAGES: The cost and maintenance is low for metal wall panels since there is possibilities for customization and availability. It is quick and easy to install and there is a small amount of scrap after it is installed. Its lifespan is from 20 to 40 years and doesn’t require as much replacement as other wall systems. They are strongly resistant to fire so insurance cost is lower for metal panels and lower cost of utility since they are insulated to resist heating and cooling. If constructed right, the metal panel seams help keep water out. Another great benefit is its lightness compared to materials like brick. It is also sustainable and energy efficient because it can be 100% recycled and still remains strong as its original state.

COMPOSITE WALL PANELS

https://www.pac-clad.com/products/wall-panels/composite-wall-panels/

INSULATED METAL PANEL

http://fmlink.com/articles/metl-span-white-paper-lists-benefits-of-insulated-metal-panels/

https://www.pinterest.com/pin/444660163193234017/

http://northclad.com/products/zn/zinc-composite/details/

https://www.pinterest.com/pin/445363850624923973/

https://www.pinterest.com/pin/479140847849370601/

TRADITIONAL METAL PANEL(SECTION)

A traditional metal panel system is connected to a metal wall stud. On the exterior of this wall system is the metal panel and on the interior is a piece of gypsum board. In between these two is a layer of air permeable waterproofing. Then there is a sheathing layer and stud cavity insulated with batt insulation. Following the batt insulation and metal studs is a vapor barrier/air barrier to block off moisture from entering the wall.

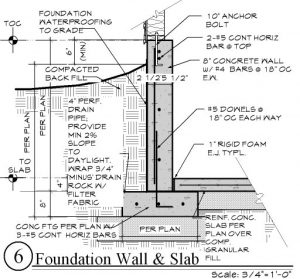

Concrete Walls can be constructed from precast concrete, poured concrete, concrete block, stucco concrete, stamped concrete and colored concrete. Precast walls can be reinforced with steel ribs. Poured concrete walls can be used for a foundation or as a retaining wall. Concrete block walls can also be used in a foundation or as a retaining/decorative wall. Stucco walls serve more as texture. It is made of a thin concrete layer that is used over an existing wall. Stamped walls are similarly created to poured concrete walls in the way it is molded. Colored concrete walls also are created by poured concrete techniques.

https://www.pinterest.com/pin/795870565369065360/

http://www.lifeofanarchitect.com/graphic-standards-part-2/

http://www.yourhome.gov.au/materials/precast-concrete

http://www.greenbuildingadvisor.com/blogs/dept/musings/foam-under-footings

After our research we noticed a few corrections we should make:

* Head architect : Frank Fusaro Jacqueline Ho

Frank Fusaro is only the partner and the company is Handel Architects.

Her project website is:

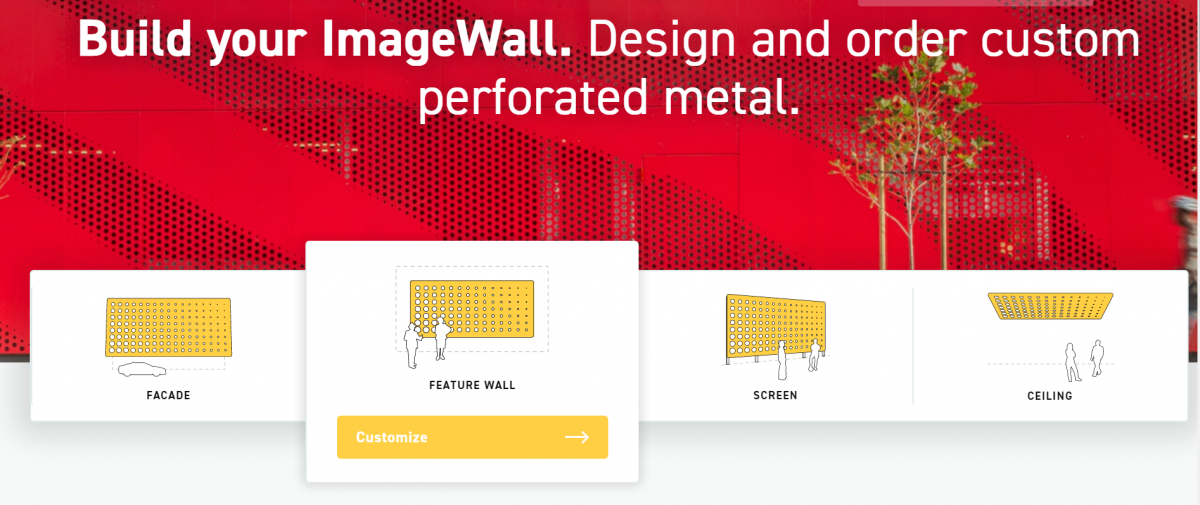

The dream hotel uses a perforated aluminum paneling system developed by Zahner called ZIRA™. Zahner has developed systems like Zira, Imagewall, inverted seam, and ZEPPS to combat the difficulties of complex steel geometry many buildings require. It allows architects to develop useful and quick prefabricated materials for buildings that need steel systems.

Zahner is very knowledgeable in the use of many materials and espcially zinc, steel, and aluminum.

Stainless Steel

According to Zahner, Stainless is:

“Stainless steels are naturally reflective. Oxidation does not develop very rapidly and the surface remains very smooth. Having a tight, smooth surface enhances the corrosion resistance of stainless steel. The more the surface is polished, the better the long-term performance.

During the production of stainless steels, the mill surface of the thick plate is cleaned of scale using strong acids. This process, known as pickling, dissolves the heavy oxides and free iron carbides that rise to the surface of the hot plate.

Further reduction of the stainless-steel thickness is performed on cold semi-polished rolls. These rolls impart a smooth, reflective sheen on the surface of the metal… Annealing the stainless steel in a controlled atmosphere will create a mirrorlike surface known as Bright Annealed…The reflective character of the various stainless-steel finishes can be divided into three categories … The Reflective Finishes can be described as those that reflect light similar to a mirror.

Disturbing the even reflective surfaces with minute surface fractures or indentations, which scatter the reflected light slightly, produces the Diffused Reflective Finishes. Because these finishes are typically applied over the Reflective Finishes, they possess a brightness, an almost glowing behavior when in strong light.

The Low Reflective Finishes possess a dull reflection. Light is effectively scattered by the rough surface. and these surfaces appear flat in most light.

Because of its chrome content stainless steel reflects 49 percent of the visible wavelength of light. It is much more heavily weighted toward the blue wavelength and captures well the tone of the sky. On cloudy days, stainless steel will appear with very little luster. This is due in part to the scattering effect of the clouds, which reduces the blue segment of the wavelength of light reaching the stainless-steel surface.

Because of the specular nature of stainless steel surfaces, slight variations in plane can affect the relative color. Moving around the surface changes the angle of view from one surface of a plate or panel relative to another. The more direct the reflection, the lighter the color. The panel that is slightly askew will appear darker in strong light. A stainless-steel surface can look dark from one angle of view, then light in color from a different angle of view. The difference can be only a few degrees out of plane. This faceted reflection is common in stainless steel thin-plate surfaces. This is also why “oil-canning” tendencies are greater in reflective metals such as stainless steel. The relative high and low points in a stainless-steel surface reflect light back to the viewer at varying angles, which create apparent visual distortions in the surface.

When fabricated and installed correctly, the reflection is not distorted by the undulating surface. Light washes over the diffused reflective surface in straight lines. The mirror reflective surfaces show straight lines as straight images and not curved images.”

———————————————————————————

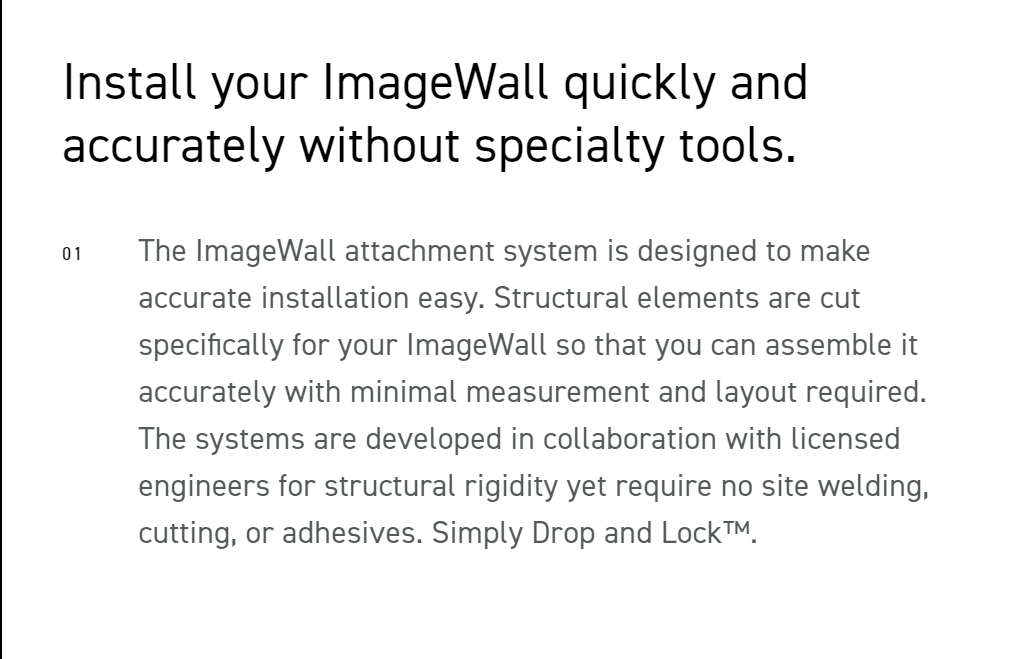

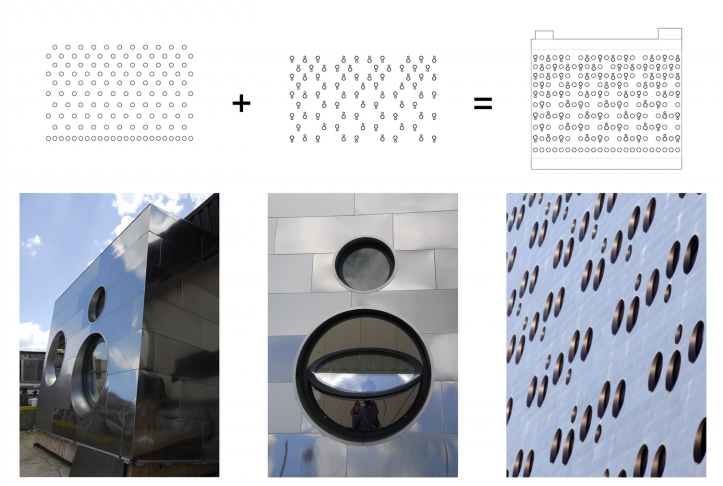

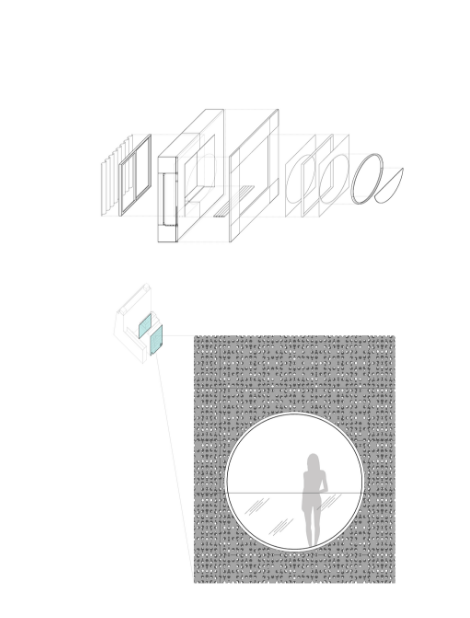

The Zira technlogy is an advanced version of the imagewall technlogy used by Zahner. They even have an app that anyone can order a metal panel with the image they desire and is prefabricated and shipped to you. Below is some images explaining the process and how it is connected.”

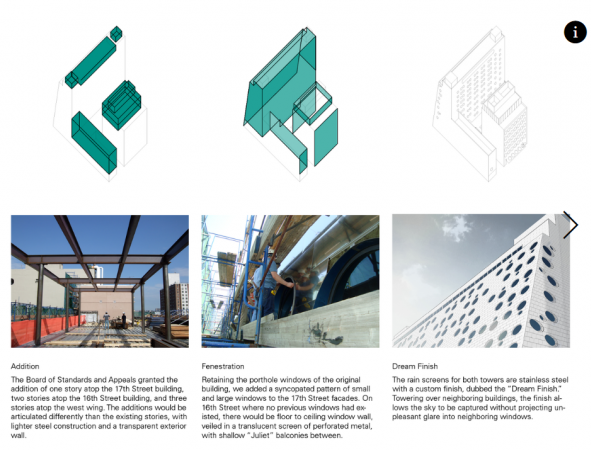

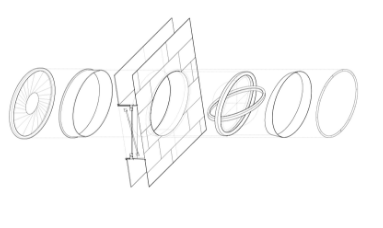

We also noticed that in the Dream Hotel, behind the aluminum paneling there is a glass curtain wall beneath the skin of the building. On other sides of the building is another type of facade system that might be a dry wall that is blanketed by a steel panel with portholes cut out. On our investigation we found some images that might give us that kind of information.

We’ve also found more research on the construction and development of this building.

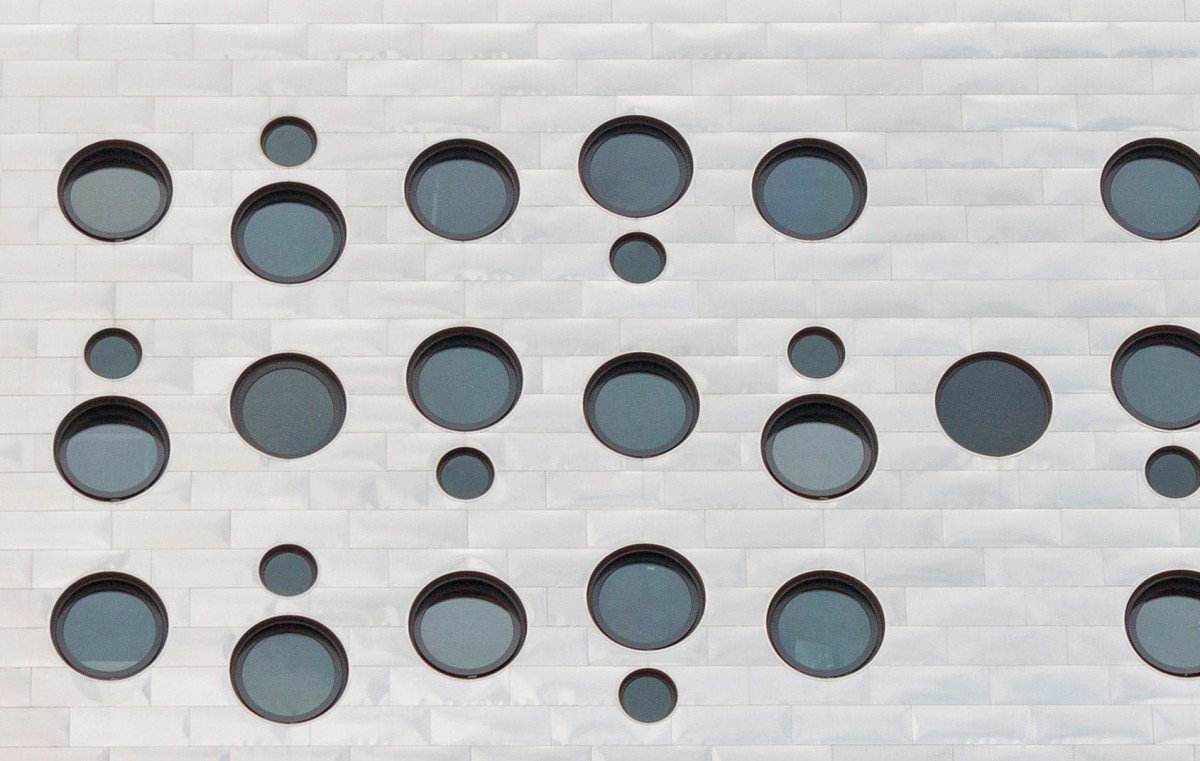

According to the managing architect this is the porthole design that is in the building.

For the sill of the windows it might look like this.

Aluminum Panel Connections

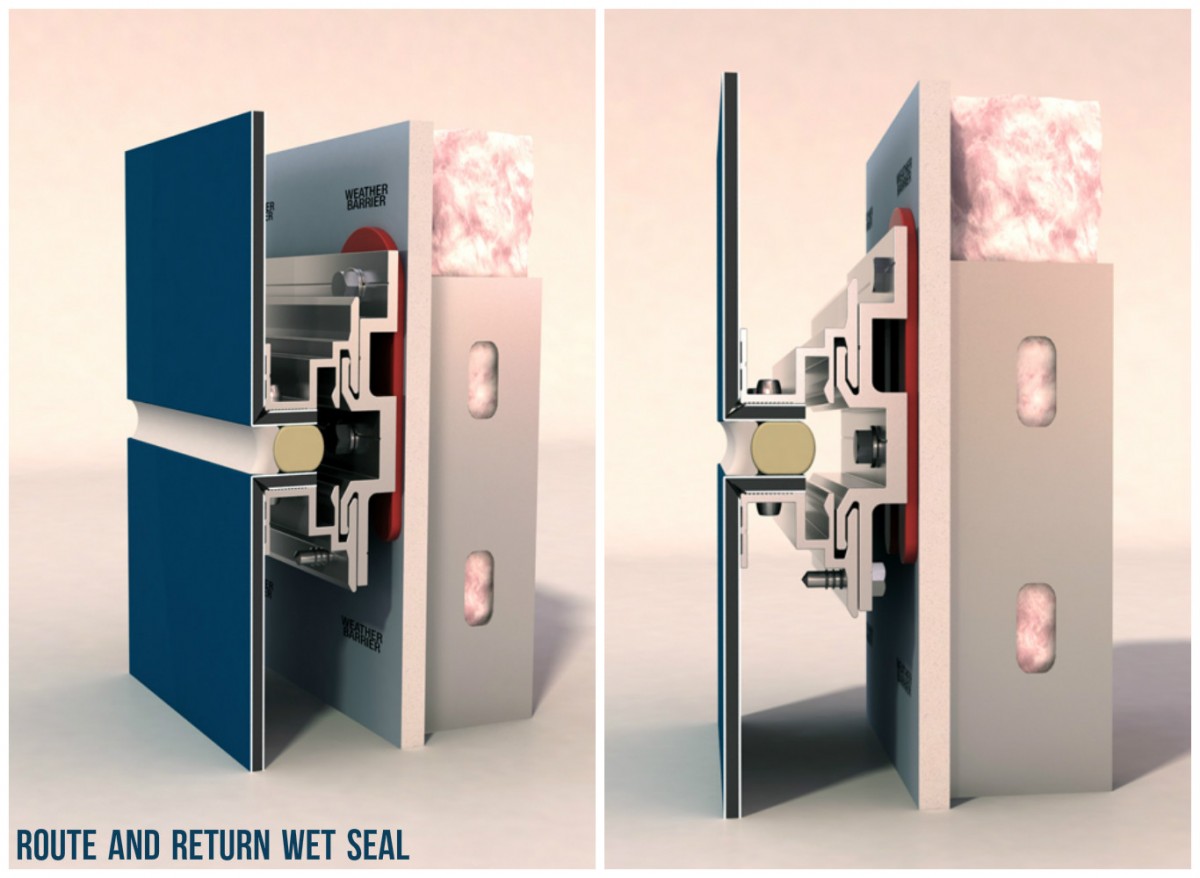

We’ve also found some information on different systems of aluminum panel connections, in our building it is a rain screen aluminum panel that allows water in, however these are other methods of having aluminum panels.

In the 15th century King Henry Vlll ordered new cannons for his warships. An openings had to be cut in the sides of the vessels to accommodate them. The openings were given the name of porte. In the French language porte refered to an door or an opening. Soon the openings became known as portholes. A circular opening has greater structural stability than a square one.In some instances, ordinary glass can be replaced by hi-tech and pressure-resistant materials, such as acrylic or quartz.

In architecture, a circular window is known as an oculus and can be found in many Renaissance and Baroque buildings.

The material generally used for building porthole are steel, aluminum, brass, bronze and iron. The glass used is created through a process called Sand-Casting, which is a mixture of silica, lime and ashes. It is heated and cooled at a consistent pace until the texture of the glass shows. Porthole is primarily a circular glass disk, known as a ‘portlight’, encased in a metal frame that is bolted securely into the façade of a structure. Portholes also consist of metal storm covers that can be securely fastened against the window when necessary. Porthole can typically measure up to two feet and weight about 100 pounds.

Our project site, the Dream Hotel in NYC, consists of a stainless steel rain screen. A rain screen is essential to manage moisture in a facade. A rain screen wall should include a water-resistant barrier, an air gap between the water-resistant barrier and the back of the siding, flashing at vulnerable penetration areas, and weep holes at the bottom of the wall.

A rain screen can be a “pressure equalized system” or a “drained and vented system.” The first type of rain screen deals with external wind loads and pressure equalization within the cavity. This system minimizes force on the wall and moves moisture through the outer wall.

The second type if rain screen system requires water to be collected and drained out of the wall. Water that penetrates the outer wall is collected and directed out of the cavity by using flashing and weep holes. If the outer wall is more airtight, pressure builds up and causes water to penetrate the interior wall and can cause decay.

Dream Downtown Hotel hired Zahner steel engineers to design stainless steel paneling with circular portholes cut with a specific patterns. The facade is constructed out of a Stainless steel perforated sheet metal that is overlayed and held in place in front of the windows and mullions on the facade. This kind of metal patterned facade is Zahner’s technlogy called Image-Wall that can use parameters to determine the patterned steel facade.

The entrance to the Dream hotel also has cantilevered canopy that filters light and has a glass inset which

The use of stainless steel paneling for the skin of the building allows for the building to blend naturally and almost disappear. However with different angles the facade seemingly changes color, from light to dark with its reflective attributes.

Links to original photographs and information. All copyrighted images belongs to A. Zahner, Dream Hotels LLC and Handel Architects.

https://www.azahner.com/works/dream-downtown