Instead of attending a winery I decided to go to All Points West Distillery. The location is 73 Tichenor St, Newark, NJ. All Points West distillery is a very nice place to visit whether, it’s to attend one of their tours or enjoy some food in their quite small or rather petite restaurant, where they also host tastings. The tasting room is quite small as well, but it’s completely overlooked by the outstanding décor. Once everyone that was attending the tour came to the tasting room, we were taken to their factory where they have barrels of their whiskeys and where the distillery machines and fermenting barrels are located. First we were taken to their Boozeum room where our tour guide Lacey gave us all a lesson on how whiskey was started and the history behind All Points West Distillery. Next, we were taken into the production room where you can see their distill machines and huge barrels where they hold the fermenting process. First, the employees were working with one boiler but now they are going to start using their new boiler to fill up larger barrels to ferment the whiskey. During the tour, Lacey mentioned their goals and one of them was finally releasing their 750 milliliter bottle because right now at the moment they are just selling pint and half pint size bottles. The two main ingredients that they use in their whiskey distillery is 80% corn and 20% molten barley. All their corn and other ingredients that they use for infusions come from a farm called Lake Free Organic where 75% of their ingredients come from. And since the distillery has tons of land, they age all their whiskey in that facility. After we was shown and explained the process of how the whiskeys are made in the distillery factory, we were taken back into their shop where we was given to try 5 kinds of whiskeys that are produced by them. However by law for one single person they are allowed to be offered 4 shots of whiskeys in the tour that we was given. For the four shots of whiskey that I tasted where Moonshine, Straight bourbon, Peated bourbon, and Grapefruit with Jalapeno. The Moonshine I kinda enjoyed because it wasn’t way to strong and it didn’t leave me a after taste nor my throat burning. The second one, the straight bourbon wasn’t bad but it left my throat burning for a good while then I went on to tasting the Peated bourbon and I kinda enjoyed that one more than the other two that I had just had. Finally it was time to taste the last one which was the grapefruit with jalapeno whiskey which caught my attention because it was a weird combination that I heard and was curious to find out how it would taste. Unfortunately I did not enjoy it at all and the aftertaste that it left was the worst part. Not only was I the only one that didn’t enjoy it but I spoke to other people who were part of the tour and they told me as well that they didn’t enjoy that one as well and they was getting that after taste a lot too. Overall I really enjoyed my visit to All Points West distillery from learning the history on whiskey’s, how All Points came to be. The experience was grand I was finally getting to taste some of the whiskey’s that they produce. It’s a tour that I would for sure recommend to friends and family to go visit for they can as well learn about the history of whiskey’s.

Category Archives: Winery and Vineyard Visit Blog

Trip to Franklin Hill Vineyard and M&M Vineyard

Franklin Hill Vineyard was the location that I chose to visit. It is an estate located on Franklin Hill Road in Bangor, PA. (Pennsylvania) and is fifth in wine production in the United States. Franklin Hill has grown from 3,000 barrels their first year to 60,000 per year. They grow French American grape varieties such as Vida Blanc, Chardonnay, Merlot, Pinot Noir, Cabernet France, and Cabernet Sauvignon. Elaine Pivinski is the owner of the Franklin Hill Vineyard and has been operating the vineyard since 1976 with no viticulture knowledge. Her vineyard is the Lehigh Valley’s oldest winery and the third winery region in Pennsylvania. Elaine had no wine-making experiences before she went into the wine business. “As early pioneers in this industry, there was no instruction manual. With a lot of hope and plenty of luck, we guided these majestic vines into rows. They in return produced an amazing crop year after year, (E.Pivinski, 2019).” Her business is successful and is running with help from her families and friends. Her first planted vines are forty-two years old and took five years to grow, while her new acre of vines is seven years old and took three years. They experienced difficulty planting the new vines, they discovered that the grass growing on the land was stealing all the vines nutrients and had to be removed. The trouble didn’t stop there, a trickle system or irrigation had to be installed because it refused to rain.

Helen who was our tour guide, she showed us everything we needed to know about the winery. During our visit there we were able to observe the very beginning of the bud break stage of the vines. Harvest of these grapes usually occurs during the second week of September and takes around seven weeks.

She explained that Elanie started the wine business with older techniques, using the technique Brix to measure sugar levels of their grapes. (S. Guide 2017) The vineyard makes a variety of different wines including red, white, fortified and rosé with a list of specialties that are delicious as their names are stimulating.

Stainless steel tanks are used for their fermentation, as supposed to using neutral Barriques/oak (wooden barrels) having had trouble keeping the quality of the Barriques and keeping pace with the demand. Most of their blends feature an alcohol level of 10-12% except for port wines which are around 20%.

Helen explained that Elaine had been producing the wines in a singular Destemmer, which is used to first crush wine grapes and then separate the grapes from the stems, multiple stainless-steel tanks, and Paper filters. However, when they discovered that not only were the paper filters unstainable but also depleting large amounts of the wine they switched to a filtration device obtained from Germany. (Fun fact, the filtration system was the same cost of the land purchased for the vineyard). Punching down the cap is a method for the vinification practiced at this vineyard along with cold stabilization for one of their wines called Evanswood. Adding oak flavors is achieved by using fabric like material filled with oak staves and chips that are attached to the bottom of the tanks.

After leaving Franklin Hill we journeyed to a vineyard called M&M Vineyard. This vineyard was only three years old. The owner and his wife were both microbiologists, they planted the grape vines in 2016.

They grow Vidal Blanc, Chardonnay, Cabernet Franc, Point Noir, Merlot, and Sauvignon Blanc. Their wine tasting only cost five dollars, and you can taste seven different types of wine. However, they only sell their wines locally, so you won’t have the chance to buy their wine unless you make the drive to their vineyard for a full wine experience. Unfortunately, we weren’t allowed to take a tour to see the inside of their winery because it is not open to the public.

From their website they describe the benefits of the land, they purchased after spending two years researching. “Nestled between the rolling hills of the Pocono Mountains and the Delaware Water Gap, our site was chosen through extensive land and soil analyses conducted throughout Northampton County. Our Vineyards’ ideal south-facing slopes made of rocky, well-drained soil, rich in weathered shales, balanced micronutrients, and generous mineralogy, provide an exceptional terroir for producing the most highly expressive wines. Also, the small batch, handcrafted, winemaking practices that we employ produce the most captivating wines in the region.”(S. Mohinder, 2019)

I really enjoyed my trips to these vineyards and have gained a large amount of knowledge and fascinating stories from the workers that we met.

References

Certified Specialist of Wine: Study Guide 2018. Washington, DC: Society of Wine Educators, 2018. Vocabulary words.

Lehigh Valley’s Oldest Winery │Franklin Hill Vineyards. (n.d.). Retrieved from https://franklinhillvineyards.com/

M&M Vineyards. (n.d.). Welcome to M&M Vineyards. Retrieved from https://mmvineyards.com/

Warwick Valley Winery

If looking for a winery to attend I would recommend the Warwick Valley Winery. The Warwick Valley Winery is a family owned business that has over 5 acres of land producing more than 100 bottles of wine a day.

As shown below this is the entrance to Warwick Valley. Since being up relatively far I would suggest this as a day trip. While driving into the place you can see the grapes and other trees growing such as apples, pear, and oranges also made into different hard liquors.

The process of making wine and all liquor starts with the viticulture. Viticulture is the process of making wine. Warwick Valley relies heavily on the process of vinification. Fermentation wise Warwick Valley uses classic oak barrels for fermentation. Vessels are used as well to produce sparkling wines. Most of there wines are racked and then left for purchase. Their wines are not typically long-aged wines that are racked for many years and purchased by the crate.

Walking through the winery on the tour was interesting to do as the tour guide was very knowledgable from the types of grapes to the crus on the branches. some varieties of grapes grown as Cabernet Franc, Chardonnay, Riesling, Pinot Gris and many more. these are all types of grapes varieties that we learned about throughout the semester and are defined within the textbook. The winery itself has a trail like process through.

the tasting room was connected to the dining hall and the store. it was a small crowded area that was run by one bar back. He was a very busy man that was doing a tasting of about 8 wines that day. You had the option to choose your vintage and your blend and then you were able to taste them. one disappointing factor of the wine tasting that is it quite cramped as its a small area.

A major highlight of this winery was the food and music. The food there was absolutely amazing serving hand made fire oven pizzas that were delicious, and crispy homestyle french fries tossed in truffle oil. And the live music was from a local band. it’s a cute place that is family friendly and just an overall fun time. If you’re looking for a winery I would recommend Warrick Valley Winery.

Bunker Hill Vineyard and Winery

The Vineyard in which I visited was Bunker Hill Vineyard and Winery in Parrish, Florida. I chose to go to this Vineyard in Florida because this was near my Tampa vacation destination. Bunker Hill was fairly easy to find on Google, but when driving, very hard to navigate, as it was surrounded by many farms. Bunker Hill was the only winery and vineyard within a 60 mile radius of Tampa. Bunker Hill was a gem, I learned so much information which will further help me in my wine education in the future, including how this was a family operated business which thrived from faith.

The viticulture practices in which Bunker Hill facilitated are plentiful. To begin, Bunker Hill makes wine out of many different fruits and even vegetables. Blueberry, lemon, lime, mango, onion and even coffee wines were made at Bunker Hill. Bunker Hill grows all of the fruit in which they make, which makes them a significant Vineyard because not many vineyards can execute this strategy. Not only do the owners grows majority of the fruit used to make their wines, but they have also been able to recycle over 90,000 wine bottles. Bunker Hill practices eco friendly production and execution in order to be track their carbon footprint. Bunker Hill abides by the Federal Law of making authentic “Natural” wines. All of the wines made at Bunker Hill are labeled, “ Grown, Vinted, Produced and Bottled”. I learned that this is very rare amongst the wine industry. Bunker Hill’s noble, which means the older wines, were typically grape wines.

When it comes to the vinification practices of the winery and vineyard, Bunker Hill grows about 95 percent of the fruit used to make their wines. The only grapes in which they use are 100 percent muscadine grapes, which are native to Florida and Georgia. These muscadine grapes are wind pollinated, which means the wind transports the pollen to allow the flowers to grow. Instead of aging their wine in oak barrels or tanks they use carboys, which are glass tanks in which they ferment the wine in. Once the must and yeast are added to the carboy, the carboy is then airlocked to prevent any oxygen or bacteria getting in and ruining the aging. Bunker Hill ages all their wines, other than the noble wines for one year. As far as the cellar, or where the wine was aged, the owners insisted that the temperature in the room is the temperature of the earth because that’s how nature thrive’s. The owners typically make natural jams from the fruit in which they made the wine, to pair with different meals. For example, I tasted about a teaspoon of strawberry jam inside the strawberry wine and was told to think of the drink as a sangria; in fact it tasted exactly like a sangria.

Being that Bunker Hill is so Eco friendly, they also advertise that they are one of the only Vegan friendly wineries in America. This is because all of their wines are unfiltered. Unfiltered wines are natural in the sense that nothing is added to the wine such as preservatives or “strainers”. Many wineries filter their wines with egg whites which now makes the wine non vegan friendly. This process can be related to raking, which is transferring wine and or filtering the wine from the following rest place. Bunker Hill’s bottling process is they use recycled glass bottles all 750ml. Once the wine has aged in a room temperature “wine cave”, for a year,the wine is then transferring directly into the bottle. One thing that I was told during my tour is that since the wines are unfiltered, when they are transferred into the bottle, they are vinted and aging continues.

This is one of the only photos I was able to capture in the wine tasting room. there was currently another group in which I did not want to take a photo of.

Citations:

Home. (n.d.). Retrieved from http://www.bunkerhillvineyard.com/

Learn about Wine. (n.d.). Retrieved from https://winefolly.com/

Society of Wine Education Textbook.

Bunkerhill Vineyard and Winery

Over spring break, I had the opportunity to visit a mom and pop vineyard/winery in Parrish, Florida. Larry and Lenora Woodham both run Bunkerhill Vineyard and Winery. This establishment has been open for over 20 years. The Woodham’s are the sole owners and built their land from the ground up. This couple was very humble, gracious, uncensored, and happy to inform us on how the establishment runs, and everything we need to know about the wine industry. The Woodham’s opened up our eyes to sustainability in the beverage and hospitality industry.

Firstly upon arrival Mr.Woodham brought us into the retail wine cave. In this cave were bottles ready for sale, and a tasting area. Mr.Woodham first broke down the wine laws to us that he had posted freely on the wall for customers to see. All of their wine is grown, produced, vinted and, bottled on the establishment. They gave us a keynote when reading wine labels, to look for those words (In the United States). Not only do they produce grape wine, but they produce wine from local fruits and vegetables. Only 3% of their fruits are outsourced. Due to them making wine from whole fresh fruit, they put natural on all of their wine bottles except for grape wines, which it is illegal. Also on their wine label includes the vintage year and various titles of local animals.

Though at Bunkerhill they do various fruit wines, they do specialize in their grape wine. The only grape variety that they use is the Muscadine grape also known as vitis rotundifolia. According to Crfg, the muscadine grape is native to southeastern United States.These grapes naturally have a thicker skin that can handle this AVA’s naturally maritime climate. In Florida they are surrounded by many lakes which moderates the heat. Florida does get some rain but when it is not enough, they use drip irrigation, with the help of solar panels according to their site. The Woodham’s informed us that harvest for them is in early august. In the specific time that we visited, the vines were just waking up from dormancy. We asked the Woodham’s about pests and how they control it. All of their practices are organic and they are also sustainable. They mentioned their main pests are racoons, whom with their hands can damage the trained vines. Therefore thy capture them unharmfully, and release them into wildlife.

The Woodham’s vinify their wines in a carboy glass inert vessel. This is done because eventually steel releases chemicals into wine and, oak barrels are very porous and unsustainable in their opinion. I inquired about the temperature of the wine cave. Mr.Whoodam said that they do not refrigerate their wine cave because they prefer their wine to be at the temperatures of the Earth. The wine case was made out of steel. The interior is made from storm damaged trees that keeps the cave from getting too warm. Only when completely necessary they use refrigeration, just to keep the wines from being too warm. As far as their sparkling wine, they prefer to do it the traditional method. According to the Society of Wine Educators, the traditonal method originated in France and is the most pricey way to sparkle wine. As usual they make their base wine in a carboy, then for the second fermentation, they do it in 750 mL bottles (which are 100% recycled from returning customers), and riddle the bottle, disgorge it, and reserve it for at least a year. Their base wines are also reserved for minimum one year in a carboy. After taking a tour of the Wine Cave, we went back to the tasting room/ retail shop and got to analyze some wines. We also had the chance to wax bottles. I didn’t get to taste but Massiah did. She tasted a sparkling red, and white. Also she got to taste a blueberry and mango wine. Ms.Lenora Woodham assisted with the wine tasting and was very knowledgeable. She even paired some of their homemade jam to pair with one of their dry wines.

Overall the experience was amazing and i’m very thankful to the Woodhams for being very informative and open.

Works Cited

Bunker Hill Vineyard and Winery, retrieved from http://www.bunkerhillvineyard.com/Home.php

Muscadine Grape, retrieved from https://www.crfg.org/pubs/ff/muscadinegrape.html

Society of Wine Educators, Certified Specialist of Wine Study Guide. 2018, Print.

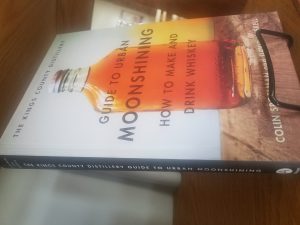

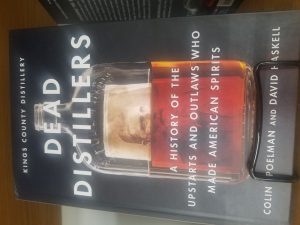

Kings County Distillery

Kings County Distillery is New York City oldest, largest and premier whiskey distillery. They started the business in 2010 in a tiny spot in Bushwick and then moved to the Brooklyn Navy Yard in 2012. At the Navy Yard I took the 3pm tour the distillery offered for 16 dollars. The first part of the tour was the experiment wall. This wall shows all the spirits that they tried that were successful, as well as the ones that never made it on the market. Then we proceeded with the whiskey war history. Where the tax distiller Clinton Gilbert was shot and killed (Poleman & Haskell 2015) page 72. Kings County distillery has 9 years of service since prohibition.

Spirits and Ingredients:

Straight Bourbon: is their main type of whiskey. The technique Kings County Distillery uses are the grain mixture which is made up of 80 percent of New York State corn and 20 percent U.K barley. It is combined with the fresh corn and then stored in the oak barrels. It has 45 percent alcohol. Aged for 2 years.

Chocolate flavored whiskey: is infused with moonshine. The flavor and the aroma from the nose comes from the shell or the husk of the coco beans, then sits 3 to 4 months in stainless steel pot still.

Moonshine: Other known as whiskey before aged in a barrel. The moonshine corn whiskey ingredients are corn make from 80 percent New York State corn and 20 percent malted barley. The moonshine is double distilled. It has 40 percent alcohol.

Peated Bourbon whiskey: Is made from malted barley that has been exposed by peat smoke. It is made up of 45 percent alcohol, from 75 percent corn and 25 percent Scottish grown peated malt.

Grape fruit jalapeno flavored moonshine: Both fruits are processed in a separate thank. However the seeds from the jalapenos are removed. The moonshine is infused with citrus, bitterness and heat on the palate.

Farming, Fermenting and distilling practices:

Kings county whiskeys are process includes mash,fermenting straining, stripping run, spirit run, proofing and aging on site. (Poleman & Haskell, 2013) page 130 to 144. Using 24 liters stainless steel stills and 5 oak fermenters made from roof tops water top which holds 40 gallon each. The straight bourbon is distilled twice in copper pots still and aged in new charred oak barrels. First they must choose the barley or corn, then malt the desired grain, extraction of the sugar (corn or barley). They are then combined with warm water also known as the mash, the reduction of carbohydrates creates sugar to activate the yeast. The result is called wort. The draff is the husk or any particles which is used for farming. Follows by fermentation which is yeast + sugar + alcohol = coz+ ethanol + heat. The yeast is then doubled to help absorb the sugar which creates the beer . It is then fermented in oak barrels. Then comes distillation where the uses copper still known spirit run as to help extract contaminants from the spirit. There are 3 alcohol that is produced from this process foreshots high in alcohol followed by the head, feints very low in alcohol and heart which is high proof alcohol right before the heart is 70 percent proof the tail is distilled water at the end. The transformation from beer to whiskey, maturation of the whiskey is where the spirit sits in charred oak barrels. Then aging in the oak barrels which adds flavor, texture on the palate and color in the appearance. Over all the experience was knowledgeable because the tour guide was familiar with his history and the AVA’s, his spirits, the fermenting process and he was able to answer random questions connecting the question to the lesson in the tour.

Reference list:

Poleman, C., & Haskell, D.,(2015). Kings County Distillery: Dead Distillers.

In-text reference: (Poleman & Haskell, 2015)

Poleman, C., & Haskell, D.,(2015). Kings County Distillery: Guide to Urban Moonshining.

In-text reference: (Poleman & Haskell, 2013)

Beverage Production Experiential Learning Analysis- Brooklyn Roasting Company

For the Project, I chose to visit a coffee roaster instead of a vineyard with a winery. I went to the Brooklyn Roasting Company, this coffee roaster expanded from a single location at 25 jay street to now three different locations. (Eldredge 2015)

The entire place looks like a warehouse and built-in coffee machines. When I spoke with the staff at the front, he was willing to talk but was kind perfunctory. Maybe there were students visit the company every year, therefore, the staff is impatient about what I was about to ask. Despite the attitude, I was able to get enough information out of his mouth because I at least made a purchase so I was a customer. I purchased a Nitro Cold Brew, I think this is a new trend about coffee because I only saw this kind brew recently. Cold brewed coffee with the infuse of Nitrogen can bring a hint of sweetness, however, I found a hint of sourness instead.

Brooklyn Roasting Company only selects the finest Arabic coffee beans from the suppliers they trust and have a direct relationship with. All beans before the roasting process will have a moisture check, only the beans with the moisture content within 11%-13% will be kept and roasted. All BRC coffee roasting process is done by fully computer programmed roasters, therefore, they were able to track the progress and control every roast. The machines they use are also environmentally friendly and more efficient than others. When the beans are roasted to the ideal roast it will be canned or bagged at the same facility, this is also part of the quality control. (BRC 2019)

After the roasting, they also send the beans to their retail store to sell. They also sell all kind of equipment needed to brew coffee.

BRC source their beans all over the place and work with all types of farmers but only when they have met with the member of the coffee co-ops and built a direct relationship because they want to make sure the coffees beans are sustainably grown and harvest. BRC also work with the Fair Trade USA to make sure the farmers they purchased the beans from are paid with a proper wage.

What makes this company unique are the combinations of all trait of them. 100% Arabic beans, Fairtrade, reusable containers, and environmentally friendly coffee roasters, all these together makes the company a great reputation company.

I like that they work with the fair trade to provide proper pay for the farmers because some companies work with the partner that pays barely anything to the farmers and uses child labor at the farm.

Reference:

About Us. (n.d.). Retrieved from https://www.brooklynroasting.com/about

Eldredge, B. (2016, March 24). Sneak Peek at the New Brooklyn Roasting Company HQ. Retrieved from https://www.brownstoner.com/brooklyn-life/sneak-peek-brooklyn-roasting-companys-new-hq-brooklyn-navy-yard/

Brooklyn Roasting Company | Brooklyn | Restaurants. (n.d.). Retrieved from https://www.nycgo.com/restaurants/brooklyn-roasting-company

Beautiful Bedell

BEDELL CELLARS

36225 Main Road, Cutchogue, New York, 11935, USA

Located in North Fork of Long Island AVA(American Viticultural Area), Bedell Cellars is home to artisanal and sustainable quality wine. Spanning over 80 acres, the friendly team at Bedell Cellars offers tours, tastings, and even event planning to host the perfect dreamy wedding. Family owned and critically acclaimed, this estate winery exhibits nothing but the best: wine, environment, service, aesthetics.

Consisting of three vineyards; Bedell, Corey Creek, Wells Road; sustainable practices throughout all ensure that the land and all surrounding it are protected. Certified sustainable for many years by the Long Island Sustainable Winegrowing organization, Bedell Cellar takes prides in all it’s viticulture and vinification practices. Grapes are grown without pesticide, hand picked for what is only needed, then made into small batches of wine. All the grape seed and skin is then composted back into the land with all the vine cane prunings to use as natural fertilizer. With these processes, there are minimal chemical affecting the land, the grapes, the farmers, and the society.

North Fork Long Island AVA consists mainly of terroir derived of glacial soils surrounded by a cool maritime climate (LIWCNY, 2015). Bedell Cellars portrays that exact of its’ AVA, with vines planted into loam and sandy gravel. Typical to the grape varieties of Long Island (Harris, 2015), Bedell produces wines from Sauvignon Blanc, Chardonnay, Cabernet Franc, Merlot, Malbec, and even some unique varieties such as Viognier, Petit Verdot, Albariño, Pinot Gris, and Syrah. Most of their wine features a light to medium body, moderate acidity and refreshing taste, that of the North Fork style. To make their wine a bit more interesting and unique to North Fork, Bedell uses 100% natural yeast indigenous to the land, derived from local fruits and flowers. Everything is hand produced, from harvesting to sorting to juicing, using solely gravity to produce wine such like the ancient times. Musts are then aged in 3 different barrels, oak barriques, stainless steel inerts, and imported clay vessels, also known as qvevri (Weltman, 2018). For blends, over 50 batches of different vintages are created to carefully and meticulously create their distinct taste. In the end, all of their wine beautifully portray North Fork’s terroir and climate, refreshingly crisp and slight mineral taste.

Arriving upon the vineyard, guests are greeted by the large and open tasting room located in their main building. Walls are shelved to hold their collection of bottles for sale, along with other merchandise such as honey specifically bottled for Bedell and souvenir items. To the right of the entrance is where the office is located, along with stairs that lead up to the intimate fire place and crow’s nest. View of the aging and bottling room cause be seen through glass panels, along with a panoramic window view of the entire vineyard. Guests are welcome to enjoy their tasting in any of these areas, along with the bar where all the wine and snacks are served.

Bedell offers a tasting flight of 5 wines for $20. Additional wine are offered for tasting at $5, with the option of a full glass, take home, or enjoying in site, all at additional charge. The tasting flight includes a rose, 2 white varieties, and 2 red varieties. A menu of snacks is offered as they do not allow outside food, but do provide the basics such as cured meats and cheese or popcorns. The tasting room personnel is extremely knowledgeable with the practices of the vineyard and how everything is done.

Many of Bedell’s bottles are labeled with beautiful artworks, while some were not. Asking the tasting personnel, he was able to explain that only the blends are labeled with an artwork, while the single grape varietal wines were just labeled as is. Furthermore, the artworks come from the owner’s private collection in the MoMa museum, thus chosen to make its presentation onto the labels.

Although the tasting room personnel was extremely helpful with any questions regarding the wine and the vineyard, there were some detailed questions that he was not able to confirm. The vineyard does offer a tour at $100 per person, in which one would have to reserve 24 hours ahead of time. For people who are not able to afford such a tour, information might be missed due to this fact. No one was able to fully describe in detail facts about the vines or give a walk through of the aging and bottling room. Even so, guests are still able to self tour around the vineyard and sit at their patio and enjoy the place. Overall, Bedell cellars is an extremely picturesque vineyard and winery but also produces quality wine that all can enjoy, having a little something for everybody.

Citations

Harris, M.. (2015). Inside New York Wine County. Wine Folly. Retrieved

from https://winefolly.com/review/guide-to-new-york-wine-country/ .

N.A.. (N.D.). Long Island Wine Country. Retrieved from https://liwines.com/terroir/

Weltman, P.. (2018). Why Ancient Winemaking Technique is Making a Comeback. Seven Fifty Daily. Retrieved from https://daily.sevenfifty.com/why-an-ancient-technique-is-making-a-comeback/

Circa Brewing Co.

This is me at Circa Brewing Co. I’ve blurred my face since I don’t like taking selfies.

For my project, I went to Circa Brewing Co. The person I spoke to is Drew, who is the head brewer. He has taught me a lot about beer and the malt used for making it.

Circa likes to stay local, so they try to get their supplies from local vendors rather than large chain suppliers.

This is how malt looks like up close.

This is malt. It is a grain and can be replaced with wheat or oats. There should be a 10% moisture level to maintain quality. If you eat it just like that, you’ll taste a burst of sweetness for a few seconds. After that, it starts to taste bitter due to the tannin. The malt has a smooth texture on the outside. When you chew it, its rough like cereal. Malt tastes dry.

This is the inside and outside of a roller mill. The aren’t any see through parts on the outside so I couldn’t get any other pictures of the inside. It grinds the malt and separates the shell. It is hooked through a pipe into a hot liquor tank.

Hot liquor tank

This is the hot liquor tank. This is where the ground malt goes to. It is important to know that a lot of water is invested into making beer. An example would be needing 2-3 cups of water to make a cup of beer. Since there is so much water being wasted (low yield), Circa tries to reuse that water for things like washing. The water can also be sterilized so it can be reused. Recycling is a big factor in the beer industry.

The mashing process takes place in this tank. For this certain tank, it can make about 200 gallons each time. The mashing process is mixing hot water and grain. It’s basically like tea, but pulling out the sugar instead of a tea bag. This process takes around an hour or so.

Above is a picture from Circa’s website. I’ve circled the kettle in red. There are slats at the bottom inside the kettle. The slats allow water to drip out. After the sugar is transferred, it becomes what we call wort. The residue left behind is sugarless and rich in protein. You can mix it with water and eat it like porridge. The kettle is hot, so it also sterilizes the sugar water. After the kettle is done processing the sugar out, you get wort. That wort is ready for hopping and boiling. The kettle takes about 30-60 minutes. It can make the beer have higher alcohol content, because it makes liquids/mixtures more concentrated.

This is called a heat exchanger. It is hooked to a tube, which can transfer beer into the conditioning tanks. The exchanger helps keep the temperature of the beer the same while it is being transported. Wasted water goes back into the hot liquor tank. The beer in the conditioning tanks are left for aging. Co2 is hooked to the tanks and the smaller the bubbles, the easier it can be absorbed. The Co2 is for the carbonation levels. From there, the beer can be canned or put into a keg.

There are 2 categories of beer, which are ales and lagers. Ale beers use top fermenting yeast, which is good at 68 degrees and lager beers use a different type of yeast at 53 degrees. A major difference between these two is the time required for production. Ale takes 11-14 days while lager takes 30. You can put the yeast to sleep at 33 degrees. The yeast can be used for several generations, but don’t use the same batch too much or you’ll get mutations. Yeast is used for fermentation.

Drew mentioned something called the NY State farmville brewery bill. This bill serves to help increase demand for local products and encourages local businesses. One of the rules on the bill is “January 1, 2024, no less than 90% of the hops and 90% of all other ingredients must be grown in New York State.” As you can see, this has a major positive effect on locals.

Circa practices the grain and hop farming. Hop can come from Yakama Valley (Located in Washington), Idaho, and other areas.

In terms of quality, some beers are cheap and others are more exquisite. The quality can affect taste and aromas. Some can taste like bourbon, water, etc. Essential oils in hops can give fruity flavors in cold beers, which people seem to love. Not only to the tongue, but beer can also be fruity to the nose. These flavors aren’t present in non-cold beers, because the flavors evaporate if boiled. Beer can have different styles and can be full-bodied, light, or etc.

There is a beer judge certification program (BJCP) for judging beer quality.

Circa is special because it has some of the freshest beer in NYC,strives to make something enjoyable, but not too overwhelming, and wants to have something for everyone.

Sources

Beer Judge Certification Program (BJCP). (n.d.). Retrieved from https://bjcp.org/

Beverage Production Experiential Learning Analysis: Franklin Hill Vineyards

The vineyard my classmates and I decided to visit for this project was the Franklin Hill Vineyard located in Bangor, Pennsylvania. The vineyard belongs to the Lehigh Valley AVA and features a mesoclimate similar to that of northern Europe giving way to produce French-American hybrid grapes. Their climate is mainly “influenced by the area’s proximity to the Atlantic Ocean and the Chesapeake inlet” (Simon, pg. 132) that ultimately moderates the climate of the AVA. Despite the size of the AVA, only about “500 acres are used under vine despite the AVA growing steadily” (Sokolin, pg. 56). Initially however, as explained to us during our tour there, the land that Elaine Pivinski, founder of the vineyard had bought in 1976 was actually not suited for grape production. The land’s main issues were the soil of the area as well as the land being too flat and plain-like featuring no hilly features to expose the grapes to sunlight evenly. Luckily enough, she was able to discover Cornell Geneva’s vineyard experiment program which helped her with starting up her business by introducing her to their grape experiments allowing her to grow in these areas. Despite the risk behind running her business based on these newly invented grapes, she went through with her goal of producing wine in Pennsylvania successfully producing 3,500 gallons of wine in her first year. She was then hit unfortunately with a long period of lack of rainfall as well as a struggle to sustain and expand her business with no viticultural experience and virtually just working by herself. Through meeting with Bonnie Pysher and recruiting mothers at school bus stops, she was able to obtain the help she needed and pull through these times. Today the winery has expanded from where it once was producing around 55,000 gallons annually.

The “old vines” at Franklin Hill Vineyards. The trickle irrigation system in place was used in times where rainfall was lacking.

During our tour, Helen who was our tour guide showed us just how much Franklin Hill Vineyard really had grown since 1976 showing us the “old vines” which were the surviving vines from 1976, and showing us the trickle irrigation system that they had implemented in order to sustain the vines during the period that had no rainfall. She then showed us their more recent vines featuring a five-acre field of 7-8-year-old grape vines and another fifteen acres they are currently working on. She explained the importance of the shale like soil used to grow their grapes as it eliminated the competing grass and greenery from stealing their resources as well as allowing the grape vine roots to grow more openly. During our visit there we were able to observe the very beginning of the bud break stage of the vines and was told that harvest of these grapes usually occurs during the 2nd week of September. They grow a variety of grapes including Vida Blanc, Chambourcin, Cayuga, Chardonnay, Zinfandel, Cabernet Franc, Pinot Noir and Cabernet Sauvignon.

The original vinification facility for Elaine featuring the stainless steel tanks, filtration system and destemmer.

An automatic bottling tool that replaced their old handmade tool and caps their bottles with screw caps.

We were then bought to their vinification facilities where again we were able to see just how much the vineyard had grown as a whole. The facility was split into multiple rooms and were essentially in order of when they were added. The first room featured Elaine’s first processing area featuring multiple tanks and filtration systems as well her “refractometer and the more old fashioned hydrometer” (Ewing-Mulligan, 2006) they used to measure the Brix levels of their grapes. She explained that the vineyard produces red, white, fortified and rosé wines on top of their specialties and uses stainless steel tanks for their fermentation, where they found that ultimately using neutral barriques in the past wasn’t able to sustain them through the demand for their wine. Most of their wines are blends and feature an alcohol level of 10-12% except for their port wines which fall around 20% alcohol level. Before obtaining their additions to their production facility, Elaine had produced all her wine in just that one room containing a singular destemmer, multiple stainless-steel tanks and a filtration device they had obtained from Germany after finding our just how unsustainable using paper filters were. When they had initially started, they bottled everything using a handmade bottling device and corked each of them by hand until obtaining their bottling machine and switching to screw caps. We were shown pictures of Elaine and her crew punching down the cap and Elaine learning how to use cold stabilization for one of their wines called Evanswood which featured tar traits and also how they use oak staves and chips as well in their wine production.

Finally, we arrived at the tasting room where we were able to taste six different wines. The wines I chose were the White Jade, Katie’s Creek, Redhead, Sir Walter’s Red, Catawba and Cake. Out of these six the one I enjoyed the most and found the most interesting was ultimately the Redhead which was a blend of Chambourcin and Merlot and was dry to the mouth with a strong vanilla and oak taste to it. Another wine that was also interesting was their vineyard’s most popular wine called Sir Walter’s Red which featured a blend of Cabernet Franc and the Concord grape producing a grapey acidic wine that tasted like strawberry jam.

After visiting Franklin Hill, we also visited M&M vineyards as well afterwards which was about a 10 minute drive away. While much smaller and newer than Franklin Hill, the owner Mohinder Sidhu and his wife who were both previously microbiologists pushed themselves to achieve their dream of opening a winery prepping their land for 7 years after an initial 2 years of research. They were able to transform the corn field that they had bought into their dream winery using different soils as well as creating 15 degree slopes to provide equal sunshine as well as grafting different vines to the rootstocks they had established.

Overall, visiting the vineyard really put into perspective everything we had learned in class and learning about the of history behind Franklin Hill was definitely an experience. Being able to meet Bonnie and listening to her stories of how she and Elaine self-taught themselves how to survive in the business as well as learning all there is to know in the winemaking business was truly phenomenal and is definitely someone you should talk to when visiting Franklin Hill vineyards.

References

-Certified specialist of wine: Study guide 2017. (2017). Washington, DC: Society of Wine Educators.

-Ewing-Mulligan, M., & McCarthy, E. (2006). Delicate differences make New World Pinots difficult to identify but an adventure to try. Nation’s Restaurant News, 40(15), 50. Retrieved from http://search.ebscohost.com.citytech.ezproxy.cuny.edu/login.aspx?direct=true&db=hjh&AN=20497331&site=ehost-live&scope=site

-Simon, A. L., & Allen, H. W. (1972). Wines of the world. London: McGraw-Hill.

-Sokolin, W. (1987). Liquid assets: How to develop an enjoyable and profitable wine portfolio. New York: Macmillan.

that is the cafe, where you can sit.

that is the cafe, where you can sit.