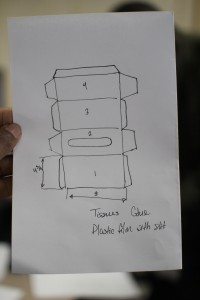

My team started the project off running to the table and picking up the box. We examined it thoroughly looking at how the corners and edges over lapped which sides interlocked. We then got a pencil and paper from a different member then Marc given the title “engineer” began to draft up a two dimensional blueprint for the box. We then went back to our groups area and determined how the pieces were connected and the different size proportions. We used a ruler app on a group member’s iPhone to measure the exact dimensions of the box.

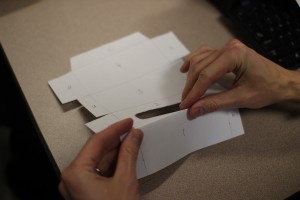

After this we began our “beta” test of building the box. This was done by Dmitry, Marc, and Samantha. The rest of the members were assigned the role of the note taker. Lesean used his camera to document the building process.

One of our members had glue and we found a pair of scissors to cut out our box template. Carrol went to the bathroom to get tissue the final component needed before closing the last end of the box.

Our team name “diversity” was a great way of defining our team. We were lucky to have someone majoring in engineering to help draw the blue print, we had individuals excellent with their hand to do precise cutting. We had grade note takers by camera and on paper. This helped making our technical manual a lot easier. Things that could’ve been improved as always was communication, slow response to emails and text messages made the process a little long but we eventually got it all together.