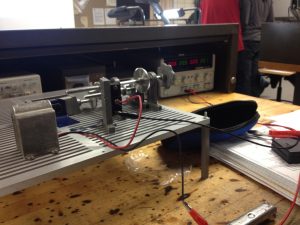

This sample above shows how it may not be recommended to set up gear wheel shafts with respect to the grooves/slots in the breadboard(note when shafts mounted on pillowblocks are parallel to the grooves, there is difficulty aligning different shafts across the “gap” space between the grooves; but if the shafts are at 90 degrees/perpendicular to the grooves then there are numerous ways to adjust the spacing from the pillowblocks sliding along the grooves to either move the shafts/gearwheels closer to other shafts/gearwheels or more distant

The picture just above these words shows shafts perpendicular to the breadboard slots/grooves so that there is easier adjustment between gearshafts spacing closer or farther (which is not depending on the standard “gap” of the breadboard as in the prior initial picture)