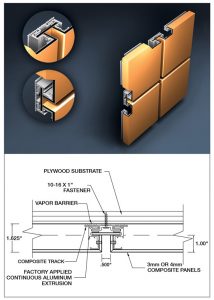

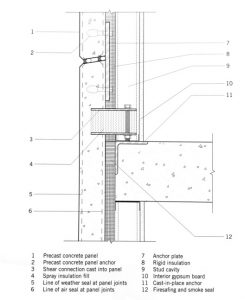

WALL PANEL: A non-structural element that forms a curtain wall with loads transferred from the wall panel to a structural frame.

WALL PANEL ADVANTAGES: The cost and maintenance is low for metal wall panels since there is possibilities for customization and availability. It is quick and easy to install and there is a small amount of scrap after it is installed. Its lifespan is from 20 to 40 years and doesn’t require as much replacement as other wall systems. They are strongly resistant to fire so insurance cost is lower for metal panels and lower cost of utility since they are insulated to resist heating and cooling. If constructed right, the metal panel seams help keep water out. Another great benefit is its lightness compared to materials like brick. It is also sustainable and energy efficient because it can be 100% recycled and still remains strong as its original state.

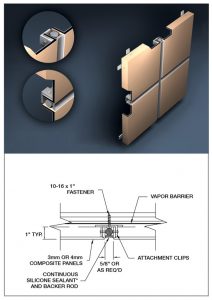

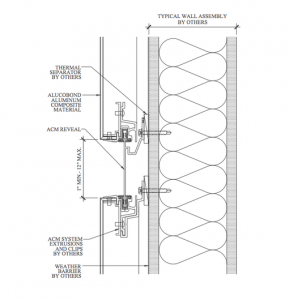

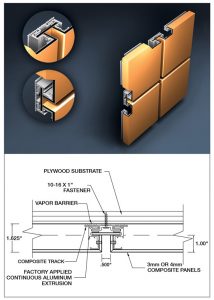

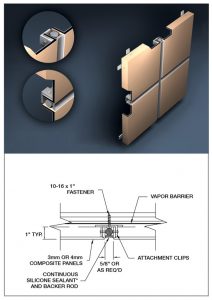

COMPOSITE WALL PANELS

https://www.pac-clad.com/products/wall-panels/composite-wall-panels/

INSULATED METAL PANEL

http://fmlink.com/articles/metl-span-white-paper-lists-benefits-of-insulated-metal-panels/

https://www.pinterest.com/pin/444660163193234017/

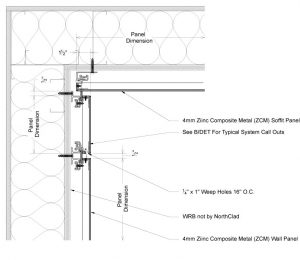

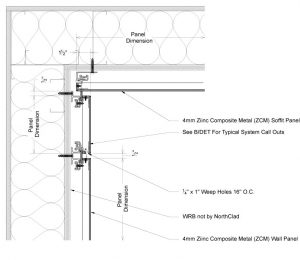

http://northclad.com/products/zn/zinc-composite/details/

https://www.pinterest.com/pin/445363850624923973/

https://www.pinterest.com/pin/479140847849370601/

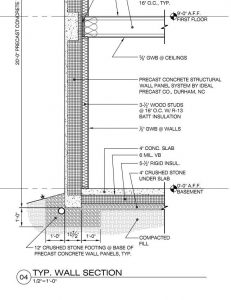

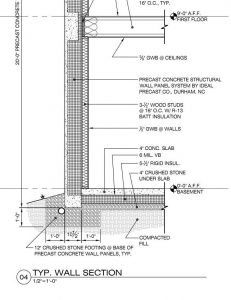

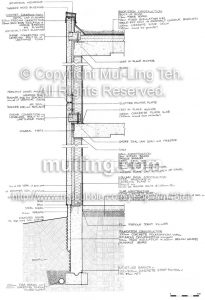

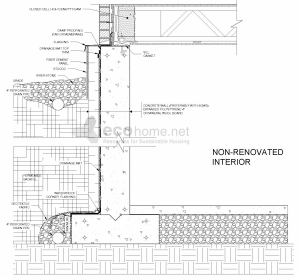

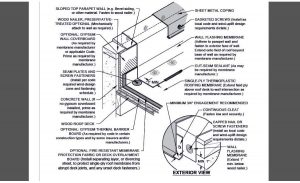

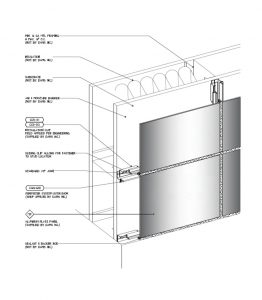

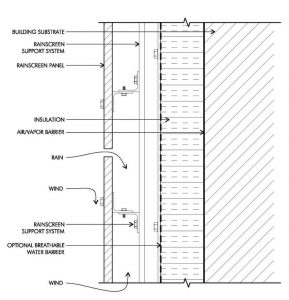

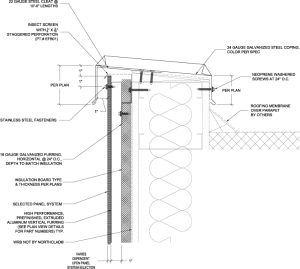

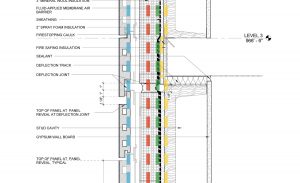

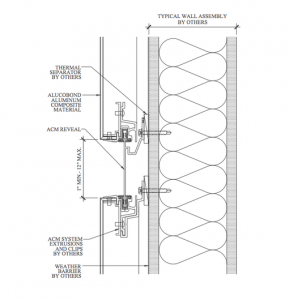

TRADITIONAL METAL PANEL(SECTION)

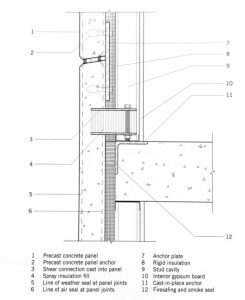

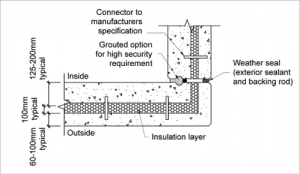

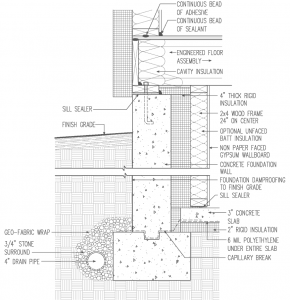

A traditional metal panel system is connected to a metal wall stud. On the exterior of this wall system is the metal panel and on the interior is a piece of gypsum board. In between these two is a layer of air permeable waterproofing. Then there is a sheathing layer and stud cavity insulated with batt insulation. Following the batt insulation and metal studs is a vapor barrier/air barrier to block off moisture from entering the wall.

http://www.philipluo.com/architecture/building/index.shtm

http://acpexpress.com/products-h-100.php