Latest Entries »

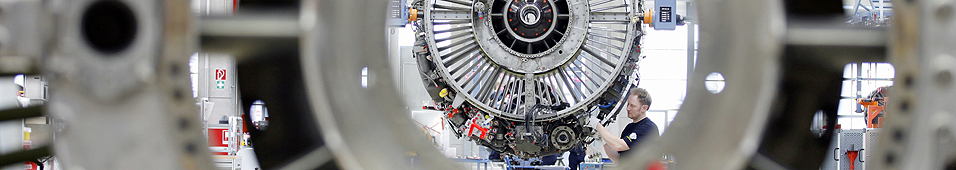

One of the most popular airliners in the sky today is the Airbus A320 twin engine aircraft. I currently work on these aircraft as an Aircraft Engineer.

One of the most popular airliners in the sky today is the Airbus A320 twin engine aircraft. I currently work on these aircraft as an Aircraft Engineer.

This airliner is manufactured by the French behemoth Airbus, who is in direct competition with Boeing. Maintenance wise the aircraft uses metric specifications and has tighter tolerances, but is a dream to work on. By the use of an extensive maintenance program, most maintenance tasks are easily doable under quick turnaround times. This benefits on time departures as well, which is an attractive thing for time constraint airlines.

These aircraft being 94 million dollars a pop says something about their quality of material, methods of manufacturing, and technology that are put into making one of these. The flight deck is a glass cockpit, which means there are no analog instruments, but instead an avionics suite with six monitors that display engine parameters, aircraft status, and the flight path. Two quiet fuel efficient engines manufactured by International Aero Engines propel the aircraft forward at 33,000 pounds of thrust.

The A320’s skin is made up of a combination of light weight aluminum and composite. This material is very critical not to get damaged during day to day operation and during ground time when the aircraft is susceptible to damage from airport vehicles. Any surface damage can lead to the grounding of an aircraft until repairs are made.

The passenger cabin takes a lot of beating from constant use and day to day stresses on seats, inflight entertainment, and carpets. These may not effect the aircraft’s ability to fly, but it gives off an image of how the airline operates or wants itself to be seen in the public’s eye. A lot of maintenance focus is placed on the interior to update the seats and services because passengers rarely see the outside of the plane, so airlines need to make a lasting impression.

With redundant systems of hydraulics, pneumatics, electrical power, and two engines; the aircraft is all about safety and reliability. Almost no interaction is required by pilots, all is controlled by logic from hundreds of onboard computers. When the computers fault out, maintenance is alerted and troubleshooting is required. Although we know the great risks of using air transportation, flying is the safest method of travel for the amount of people planes move. The A320 is one of the most used aircraft around, flying almost twenty hours a day. To keep it in shape, maintenance overseas its lifeline and extends it.

My experience working on this aircraft has been a positive learning curve. The aircraft share similarities with other aircraft I’ve worked on, but makes itself unique in respect to a unified alert system and easy access to maintenance on the engines and the fuselage. The parts are bigger and heavier but the aircraft is sturdier. Link

Growing up loving to disassemble and reassemble things shaped what I would do in my future. I had a passion for understanding the inner workings of mechanisms. Coming from a family of architects and engineers, I gained the abilities of problem solving and utilizing the resources that were available to me.

Growing up loving to disassemble and reassemble things shaped what I would do in my future. I had a passion for understanding the inner workings of mechanisms. Coming from a family of architects and engineers, I gained the abilities of problem solving and utilizing the resources that were available to me.

So I attended Aviation High School in Long Island City to learn several types of trades and exit with an FAA license. Those trades included welding, riveting, soldering, and other valuable skills which would come in handy in my future job. After high school I started attending New York City College of Technology in hopes to become an engineer. After a year of searching for a job in the licensed field, I was hired by American Eagle Airlines as an aircraft technician. I expanded my knowledge and skills in the field while doing the same with my engineering classes in college.

These two sources of experience and knowledge enlightened me to one day expand into a hybrid career field of the space exploration industry. Since starting out I have come a long way. I have moved on to a better job and I am slowly getting closer to achieving a bachelors degree. My hopes are to learn all I can from both places and make myself a well rounded individual.

Hey Readers, I have made a guest post on Henry Tam’s “Food Adventure” blog (Link). The post is about growing vegetables in Space. Through the use of a chamber with LED lights and an environmentally controlled environment, astronauts will be able to enjoy fresh veggies. Soon to be sent up to the International Space Station, the cargo will include vegetables and the chamber to join the space team, where they will study how plants grow in weightlessness. Besides the benefits of having healthy food in space, the veggies will also recycle air and water. Read more about this on Henry’s blog.

What’s up readers?! Henry Tam here, from Henry’s Food Adventures. Today, I’m going to be guest blogging about the use of Robot Machinery and food production and it’s pros on Husaan Iqbal’s blog.

Have you ever thought about how that piece of steak you’re eating for dinner ended up on your plate? Chances are that the piece of cow you’re eating has been part of robot machinery processing. The use of robot machinery plays a significant role in the food industry in terms of processing speed, and how fast the unfinished parts of the foods end up on the shelves of supermarkets and later onto the plates of the consumers.

The use of robot machinery will also cut down on the labor hours of factory workers. Let’s face it…sooner or later, a majority (if not all) of human labor is going to be replaced by robot machinery. The food management wouldn’t have to pay its factory workers anymore, and flawed human error in factories will eventually diminish. We wouldn’t have to worry as much about viruses appearing in the stomachs of consumers anymore, since there is less human hand interaction with animal meats. From a human worker’s perspective, injuries like chopped off arms and worry about blood getting into the food supply will also diminish. Everything will be done with machinery. Also, machines can work for a much longer period than any human can. There are only 24 hours in a day, we need our sleep. Let the machines and robots do it’s work.

All these points are clearly explained in the following Robotworx article.

http://www.robots.com/blog/viewing/how-robots-are-changing-the-face-of-food-production

This is an example of complex machinery that can produce 360 gourmet burgers in one hour!

This burger was made completely by robot machinery.

Being a guest poster, I may not be very knowledgeable about the robot machinery industry and how food is produced but, you can check out my food blog since we’re on the topic of food.https://openlab.citytech.cuny.edu/htam1993/

I’m pretty sure that the foods provided in New York City’s restaurants and food carts have somehow been involved in the robot machinery process!

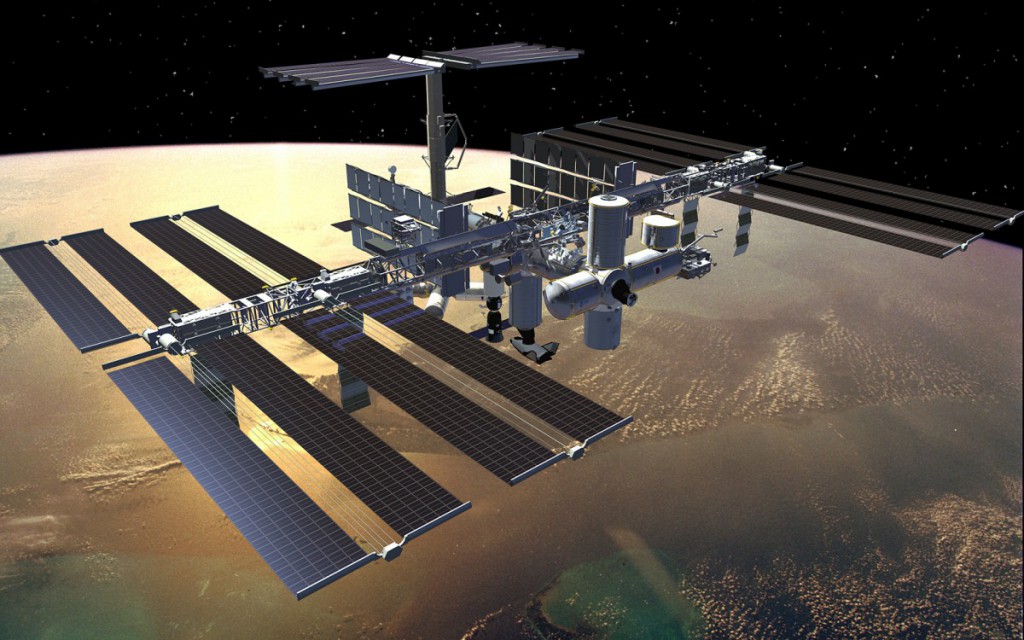

Today’s blog topic concerns our depiction of Space as an alien environment, cold and shallow. As the majority of Humans have never experienced the conditions of Space and probably never will, we can’t say we haven’t been there. The closest thing Humans have to living in Space is the International Space Station, which lives in low Earth orbit. The image of the ISS is intimidating and lifeless, but shows our accomplishments to build and occupy a lab in Space the size of a football field. The Space Station is a border-less collaboration of many nations that build and experiment for the sciences. It is the longest occupied human presence in Space, yet is peaceful and unaffected by human relations down on Earth. All the violence, all the bias motives, and all the politics don’t reach the ISS, everything remains quite and neutral up here. A person can literally get away from it all up in Space. This image is from one of NASA’s renderings that show their great accomplishments of sending and building the parts and people that make the ISS possible. The image shows the completed International Space Station in all its glory, which is available as wallpaper for desktops of Space enthusiasts. What’s appealing to me about this image is its calmness. With all the extravagant efforts and restless nights planning and executing every peace of the Space Station, it finally floats finished but not forgotten. Although the Space Station is a technology mecca itself, the work being performed inside it is also revolutionary. Unlike other visual media in my blog, this one displays something that already orbits Space, a reliable and proven machine which has made other discoveries possible. The image encourages me to keep working towards a field with potential to build something like the ISS and bring us closer to Space. What I hope others will find appealing about this image as i do is that Space has no ceiling, and neither should our ambitions to grasp it.

Today’s blog topic concerns our depiction of Space as an alien environment, cold and shallow. As the majority of Humans have never experienced the conditions of Space and probably never will, we can’t say we haven’t been there. The closest thing Humans have to living in Space is the International Space Station, which lives in low Earth orbit. The image of the ISS is intimidating and lifeless, but shows our accomplishments to build and occupy a lab in Space the size of a football field. The Space Station is a border-less collaboration of many nations that build and experiment for the sciences. It is the longest occupied human presence in Space, yet is peaceful and unaffected by human relations down on Earth. All the violence, all the bias motives, and all the politics don’t reach the ISS, everything remains quite and neutral up here. A person can literally get away from it all up in Space. This image is from one of NASA’s renderings that show their great accomplishments of sending and building the parts and people that make the ISS possible. The image shows the completed International Space Station in all its glory, which is available as wallpaper for desktops of Space enthusiasts. What’s appealing to me about this image is its calmness. With all the extravagant efforts and restless nights planning and executing every peace of the Space Station, it finally floats finished but not forgotten. Although the Space Station is a technology mecca itself, the work being performed inside it is also revolutionary. Unlike other visual media in my blog, this one displays something that already orbits Space, a reliable and proven machine which has made other discoveries possible. The image encourages me to keep working towards a field with potential to build something like the ISS and bring us closer to Space. What I hope others will find appealing about this image as i do is that Space has no ceiling, and neither should our ambitions to grasp it.

CHANG’E-5

C hang’e-5 will be an unmanned Chinese Lunar Exploration mission, which will be landing on the moon in 2017. The mission will be a sample return one, which will return 2 kilograms of moon soil and rock samples back to Earth. The probe will be launched into orbit by the Long March 5 rocket from Hainan Island. By the assistance of landing cameras, optical cameras, a gas analyzing instrument, other sampling instruments, and a drilling rig; the probe will softly land on Moon’s surface and dig to collect lunar soil 2 meters below the surface. Once the probe has what it needs, it will launch back into orbit and return to Earth in a return module. Chang’e-3 and Chang’e-4 probes will be sent on a separate mission in 2015 to not return, but set the stage for Chang’e-5 successful mission of returning moon sample in 2017. Link

hang’e-5 will be an unmanned Chinese Lunar Exploration mission, which will be landing on the moon in 2017. The mission will be a sample return one, which will return 2 kilograms of moon soil and rock samples back to Earth. The probe will be launched into orbit by the Long March 5 rocket from Hainan Island. By the assistance of landing cameras, optical cameras, a gas analyzing instrument, other sampling instruments, and a drilling rig; the probe will softly land on Moon’s surface and dig to collect lunar soil 2 meters below the surface. Once the probe has what it needs, it will launch back into orbit and return to Earth in a return module. Chang’e-3 and Chang’e-4 probes will be sent on a separate mission in 2015 to not return, but set the stage for Chang’e-5 successful mission of returning moon sample in 2017. Link

NASA’s MAVEN ORBITER

MAVEN, short for Mars Atmosphere and Volatile Evolution, is a Martian climate change probe capable of making unprecedented observations of the planet’s atmosphere. Launched on November 18th 2013, the orbiter will be inserted into areocentric elliptic orbit of Mars on September 22nd 2014. As part of the Mars Scout Program, the $671 Million MAVEN spacecraft will study Mars’ upper atmosphere to explore how the planet may have lost its atmosphere and water over time. Nine instruments will make up the probe, which was built in collaboration with UC Berkley, University of Colorado Boulder, and Goddard Space Flight Center. MAVEN’s instruments will measure characteristics of Mars’ atmospheric gases, atmosphere, ionosphere, and their relationship with solar winds. MAVEN will perform measurements while in orbit over a period of one Earth year, with five low altitude passes to sample the upper atmosphere. Link

https://www.youtube.com/watch?v=n7Pyj8A5vn4

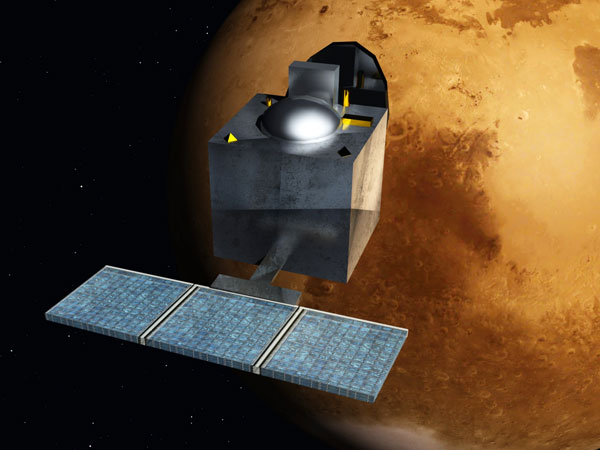

MARS ORBITER MISSION (MOM)

India’s first orbiter to Mars, Mangalyaan, is closing in on its final destination through a 300 day mission traveling at 28 km/s. Launched in November of 2013, the 1337 kg spacecraft is carrying five instruments that will study a range of things including early signs of life on the red planet and its atmosphere. This particular mission is a demonstration mission to test the technologies required for design, planning, and operation of future Space missions. The orbiter is equipped with a Photometer, Composition Analyzer, Color Camera, Methane Sensor, and a Thermal Infrared camera. All the information procured from these instruments will be down-linked to Earth through Antennas during regular communication sessions. Hopes are to explore Mars’ surface, morphology, and mineralogy as well as to exercise the capabilities of deep space communication, navigation, and management. If all goes well, the Mangalyaan Orbiter will arrive into Mars’ orbit on September 24th of this year, 2 days after NASA’s Maven Orbiter; which will be the next topic of this series. Link