Stainless Steel Rainscreen Panel

Stainless Steel Rainscreen Panel

Rainscreens offer many benefits for exterior wall performance and maintenance. This reliable building envelope resists the elements, and protects against air and water infiltration-provided their connectors are specified correctly.

Will we need exterior insulation?

Yes. Exterior insulation has almost become the design standard in colder climate zones from North Carolina up the East Coast over to the Pacific Northwest. One of the most significant considerations we have seen for specifying the connection of rainscreen panels to the building is the emphasis on the effectiveness of the exterior insulation, as this design approach is so popular due to building codes according to Brian Nelson, general manager at Knight Wall Systems, Deer Park, Wash.

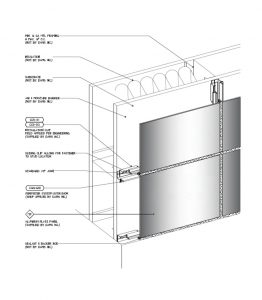

It’s important that the rainscreen connector be easily adjustable so workers in the field can easily fine-tune the installation to achieve precision. “The beauty of a rainscreen is that the waterproofing is taken care of behind the scenes-the rhythm of the rainscreen panels is independent of the waterproofing joints,” says San Francisco-based architect Charles F. Bloszies, FAIA.

“I am more concerned with the structural components beneath the panel,” he says. “The quality of the connections you don’t see are often more important than the finished surface you do see.” says Christopher Costanza, RA, AIA, LEED AP, architect at 9X30 Design Architecture LLP, Rochester, N.Y.

Metal’s Weatherability

Open-joint rainscreen systems are designed to let limited moisture in, so architects must pay close attention to metal’s weatherability when specifying their connectors. A combination of dissimilar metal materials can cause cathodic corrosion. In some cases materials such as aluminum; will corrode if it is near dissimilar metals such as copper which leads to corrosion.

“Aluminum weathers well, as long as it’s not placed up against another dissimilar metal,” says John Barbara, AIA, LEED AP, senior associate at LEO A DALY, Washington, D.C. “If steel and aluminum are used together, a coating is needed to separate the two. Steel-only connectors need to be either coated or galvanized.

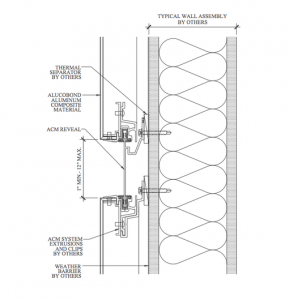

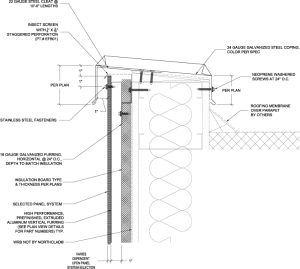

Reducing Thermal Bridging

“In a perfect world, we would use a fiberglass clip, which is a localized thermal break you attach to a hat channel,”says, Alex Terzich, AIA, of Minneapolis-based Hammel, Green and Abrahamson “But these are expensive and it’s often not in the cards for us to do that. So we look at different scenarios. Do we use intermittent Z-girts? These localized points of penetration through the insulation work well thermally, but they require a lot more layout and time. Do we use two lines of Z-girts? [They are] horizontals, with verticals on top of that, and where they cross is the one thermal bridge, which helps reduce thermal transmission. It’s a good option but also more material, more time, more cost. What we usually specify is a conventional, continuous linear Z-girt that’s bridging through the insulation, then we take that thermal bridge into account when we specify the insulation type and thickness to make sure we still meet the code-required system Uvalue requirement for the wall.”

Obviously, there are many details to rainscreen connector specification and many others not discussed in this article. Barbara believes it’s these details that often make or break a project, and bring it to the next level. “It really comes down to getting those details finessed,” he says. “The quality of the design documents is critical, but even more important is the builder’s ability to execute them, so good detailing that is buildable and resolved in the studio is essential.”

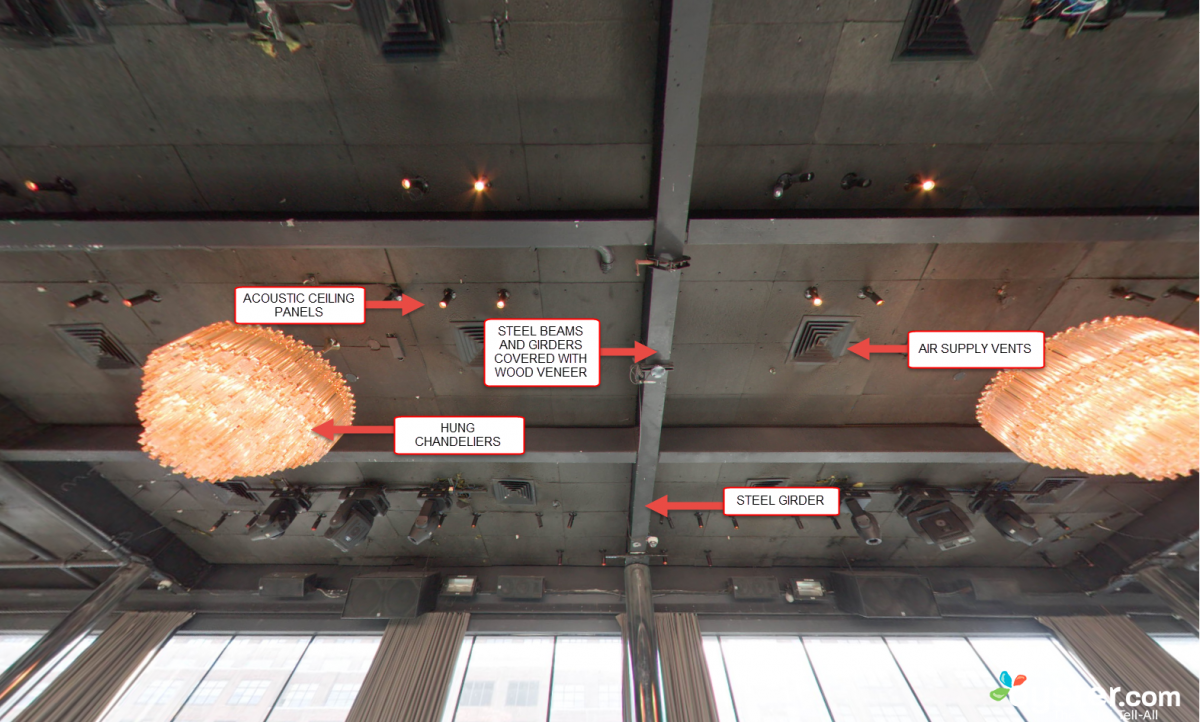

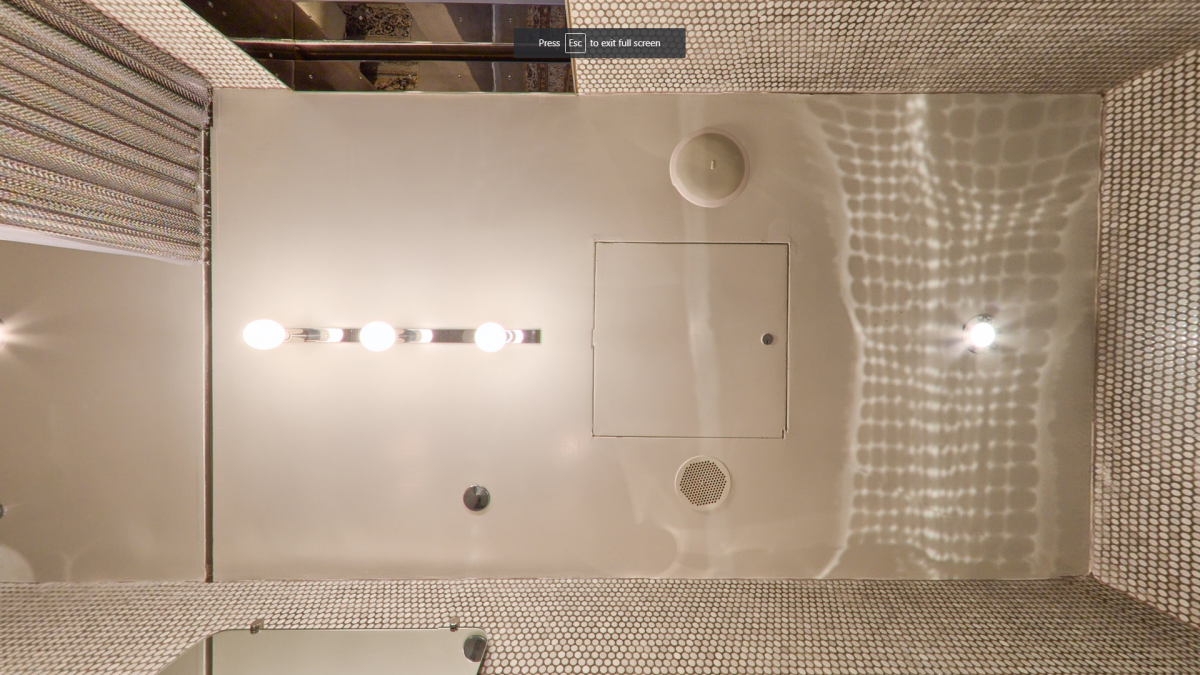

Reflected Ceiling Details and Information

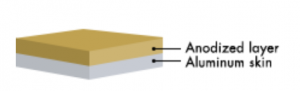

Anodize Aluminum Paneling

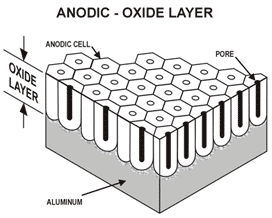

WHATS IS ANODIZING?

It is an electrochemical process that converts the metal surfaces into decorative, durable, corrosion- resistance, anodic oxide finish.

DRI DESIGN

SLOGAN :

“NO SEALANTS, GASKETS OR BUTYL TAPE IN THE PANEL JOINTS MEAN NO DIRTY STREAKS OR MAINTENANCE.”

Anodize Aluminum Panels:

Overview:

Successfully combines science and nature to create a great form of metal finish. The dense surface of the Aluminum is created utilizing the natural oxidation process and adding electricity and chemical to enhance the process and well as the outcome. This Aluminum process bring out the natural variation in colors which is expected.

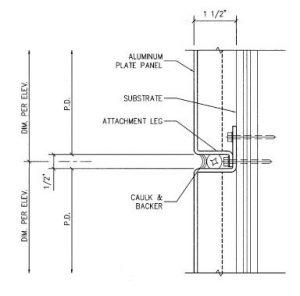

PANEL INFO

Specification:

System Dimension: 1-1/4” Nominal

Material: Aluminum

Material Thickness: .08” standard (other gauges available)

Panel Joint: ½” Nominal Standard (1/8” to 1”)

Finish: Clear, Bronze, Champagne, and Black Anodizes

Weight: Less than 2 pounds per square foot

PRO:

- Exceptional abrasion Resistance, corrosion, chemical and solvents.

- Cost efficient

- Available in one-part or two-part panels.

- The anodize panel reveals the natural beauty of Aluminum while enhancing it strength and it aesthetic abilities.

CONS:

- Requires special processes to be welded.

- Prone to sever spring break.

- Abrasive to tooling.

Team Member Materials

Tom:

- (Image Wall) Perforated Stainless Steel Rainscreen

- Stick Glass Curtain Wall system

Yocelyne:

- Metal Panel Wall

- Concrete Wall

Chandanie:

- Anodized aluminum wall

- Brick veneer wall

Metal Panel Walls

WALL PANEL: A non-structural element that forms a curtain wall with loads transferred from the wall panel to a structural frame.

WALL PANEL ADVANTAGES: The cost and maintenance is low for metal wall panels since there is possibilities for customization and availability. It is quick and easy to install and there is a small amount of scrap after it is installed. Its lifespan is from 20 to 40 years and doesn’t require as much replacement as other wall systems. They are strongly resistant to fire so insurance cost is lower for metal panels and lower cost of utility since they are insulated to resist heating and cooling. If constructed right, the metal panel seams help keep water out. Another great benefit is its lightness compared to materials like brick. It is also sustainable and energy efficient because it can be 100% recycled and still remains strong as its original state.

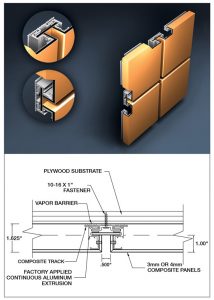

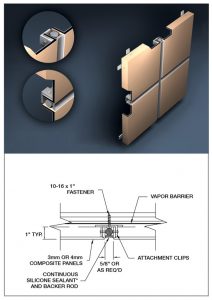

COMPOSITE WALL PANELS

https://www.pac-clad.com/products/wall-panels/composite-wall-panels/

INSULATED METAL PANEL

http://fmlink.com/articles/metl-span-white-paper-lists-benefits-of-insulated-metal-panels/

https://www.pinterest.com/pin/444660163193234017/

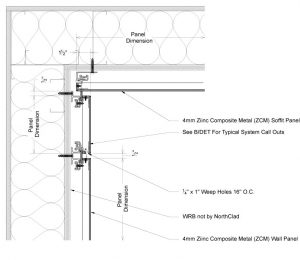

http://northclad.com/products/zn/zinc-composite/details/

https://www.pinterest.com/pin/445363850624923973/

https://www.pinterest.com/pin/479140847849370601/

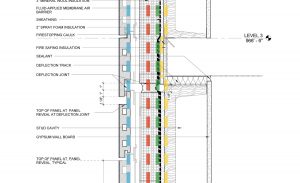

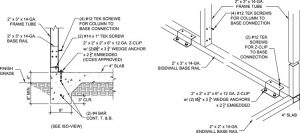

TRADITIONAL METAL PANEL(SECTION)

A traditional metal panel system is connected to a metal wall stud. On the exterior of this wall system is the metal panel and on the interior is a piece of gypsum board. In between these two is a layer of air permeable waterproofing. Then there is a sheathing layer and stud cavity insulated with batt insulation. Following the batt insulation and metal studs is a vapor barrier/air barrier to block off moisture from entering the wall.

Porthole Window/ Bull Eye Window

WHAT ARE PORTHOLE WINDOWS?

History:

In the 15th century King Henry Vlll ordered new cannons for his warships. An openings had to be cut in the sides of the vessels to accommodate them. The openings were given the name of porte. In the French language porte refered to an door or an opening. Soon the openings became known as portholes. A circular opening has greater structural stability than a square one.In some instances, ordinary glass can be replaced by hi-tech and pressure-resistant materials, such as acrylic or quartz.

In architecture, a circular window is known as an oculus and can be found in many Renaissance and Baroque buildings.

HOW ARE PORTHOLE WINDOW MADE?

Structure:

The material generally used for building porthole are steel, aluminum, brass, bronze and iron. The glass used is created through a process called Sand-Casting, which is a mixture of silica, lime and ashes. It is heated and cooled at a consistent pace until the texture of the glass shows. Porthole is primarily a circular glass disk, known as a ‘portlight’, encased in a metal frame that is bolted securely into the façade of a structure. Portholes also consist of metal storm covers that can be securely fastened against the window when necessary. Porthole can typically measure up to two feet and weight about 100 pounds.

RAIN SCREEN [Research]

What is a rain screen?

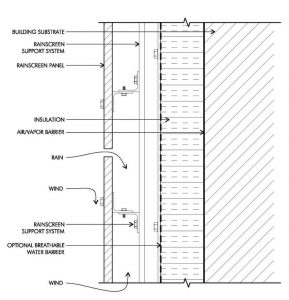

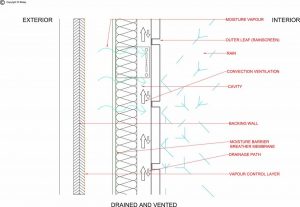

Our project site, the Dream Hotel in NYC, consists of a stainless steel rain screen. A rain screen is essential to manage moisture in a facade. A rain screen wall should include a water-resistant barrier, an air gap between the water-resistant barrier and the back of the siding, flashing at vulnerable penetration areas, and weep holes at the bottom of the wall.

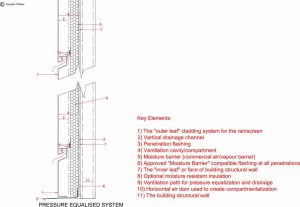

Types of rain screens.

A rain screen can be a “pressure equalized system” or a “drained and vented system.” The first type of rain screen deals with external wind loads and pressure equalization within the cavity. This system minimizes force on the wall and moves moisture through the outer wall.

The second type if rain screen system requires water to be collected and drained out of the wall. Water that penetrates the outer wall is collected and directed out of the cavity by using flashing and weep holes. If the outer wall is more airtight, pressure builds up and causes water to penetrate the interior wall and can cause decay.

Research

The Dream Hotel

Welcome to our project of our case study analysis of the Dream Hotel located at 355 W 16th St in Chelsea. The building has its historical roots as well as modern renovations where our team members, Tom, Mikayla, Yocelyn, and Lisa will be analyzing the structural details of the building with the guidance of Professor Paul King at City Tech. These studies will focus on the building technlogy of Dream Hotel, we will be learning how to research a building and to study every component via the tool of Revit and our understanding of architecture so far.

Please stay tuned for future posts and feel free to leave us a comment or contact us directly.

-Tom