Stainless Steel Rainscreen Panel

Stainless Steel Rainscreen Panel

Rainscreens offer many benefits for exterior wall performance and maintenance. This reliable building envelope resists the elements, and protects against air and water infiltration-provided their connectors are specified correctly.

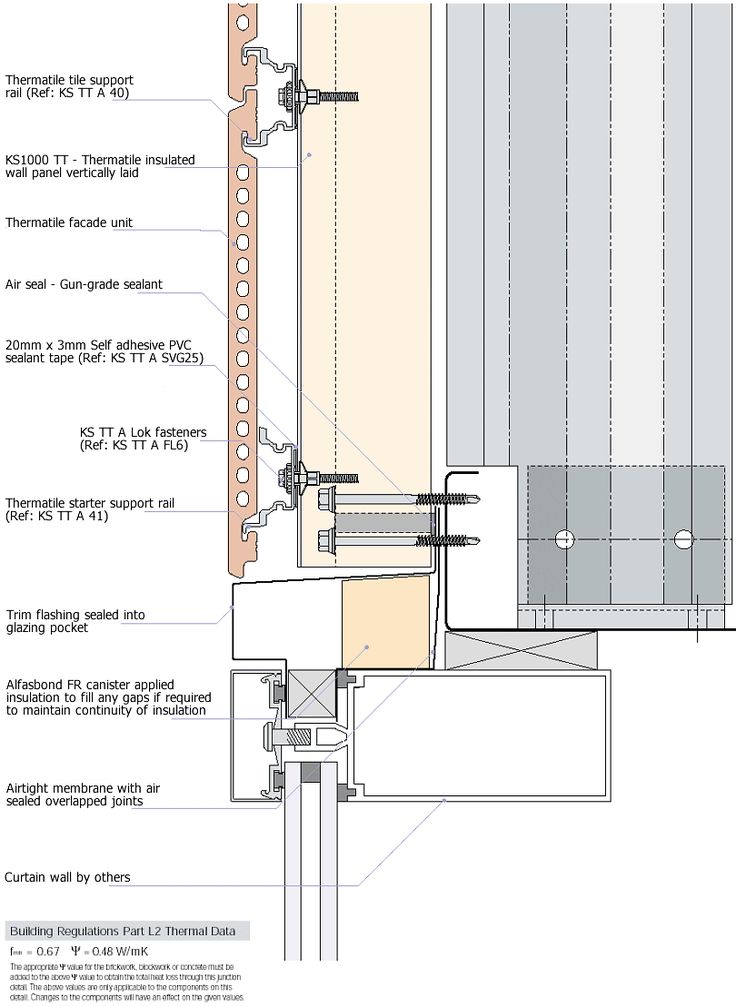

Will we need exterior insulation?

Yes. Exterior insulation has almost become the design standard in colder climate zones from North Carolina up the East Coast over to the Pacific Northwest. One of the most significant considerations we have seen for specifying the connection of rainscreen panels to the building is the emphasis on the effectiveness of the exterior insulation, as this design approach is so popular due to building codes according to Brian Nelson, general manager at Knight Wall Systems, Deer Park, Wash.

It’s important that the rainscreen connector be easily adjustable so workers in the field can easily fine-tune the installation to achieve precision. “The beauty of a rainscreen is that the waterproofing is taken care of behind the scenes-the rhythm of the rainscreen panels is independent of the waterproofing joints,” says San Francisco-based architect Charles F. Bloszies, FAIA.

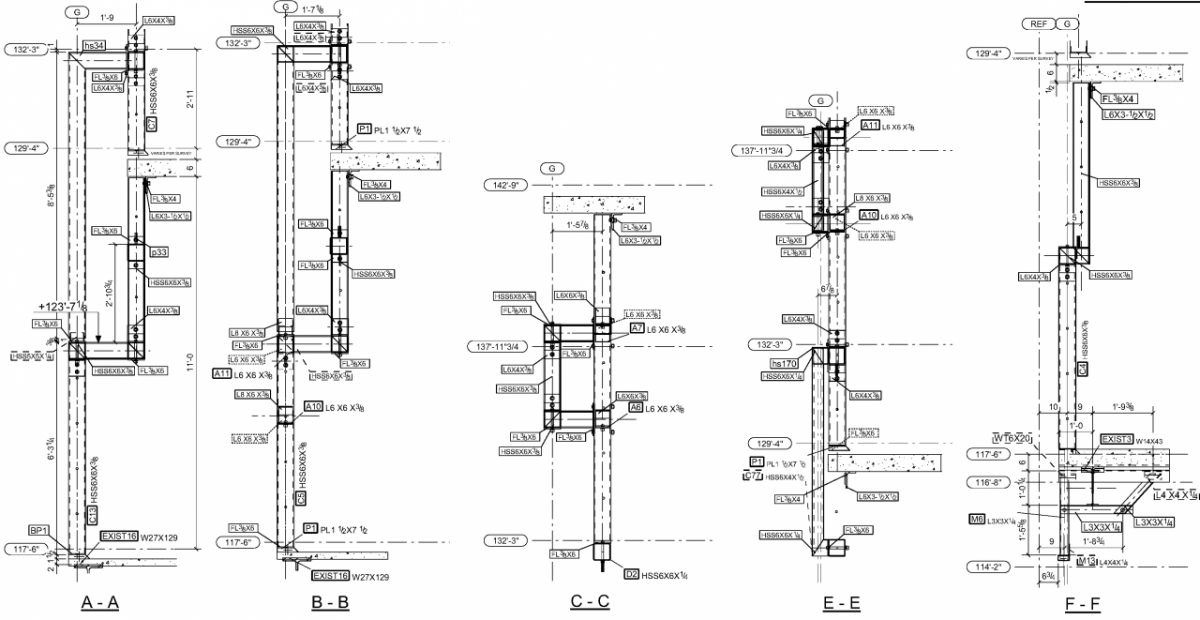

“I am more concerned with the structural components beneath the panel,” he says. “The quality of the connections you don’t see are often more important than the finished surface you do see.” says Christopher Costanza, RA, AIA, LEED AP, architect at 9X30 Design Architecture LLP, Rochester, N.Y.

Metal’s Weatherability

Open-joint rainscreen systems are designed to let limited moisture in, so architects must pay close attention to metal’s weatherability when specifying their connectors. A combination of dissimilar metal materials can cause cathodic corrosion. In some cases materials such as aluminum; will corrode if it is near dissimilar metals such as copper which leads to corrosion.

“Aluminum weathers well, as long as it’s not placed up against another dissimilar metal,” says John Barbara, AIA, LEED AP, senior associate at LEO A DALY, Washington, D.C. “If steel and aluminum are used together, a coating is needed to separate the two. Steel-only connectors need to be either coated or galvanized.

Reducing Thermal Bridging

“In a perfect world, we would use a fiberglass clip, which is a localized thermal break you attach to a hat channel,”says, Alex Terzich, AIA, of Minneapolis-based Hammel, Green and Abrahamson “But these are expensive and it’s often not in the cards for us to do that. So we look at different scenarios. Do we use intermittent Z-girts? These localized points of penetration through the insulation work well thermally, but they require a lot more layout and time. Do we use two lines of Z-girts? [They are] horizontals, with verticals on top of that, and where they cross is the one thermal bridge, which helps reduce thermal transmission. It’s a good option but also more material, more time, more cost. What we usually specify is a conventional, continuous linear Z-girt that’s bridging through the insulation, then we take that thermal bridge into account when we specify the insulation type and thickness to make sure we still meet the code-required system Uvalue requirement for the wall.”

Obviously, there are many details to rainscreen connector specification and many others not discussed in this article. Barbara believes it’s these details that often make or break a project, and bring it to the next level. “It really comes down to getting those details finessed,” he says. “The quality of the design documents is critical, but even more important is the builder’s ability to execute them, so good detailing that is buildable and resolved in the studio is essential.”

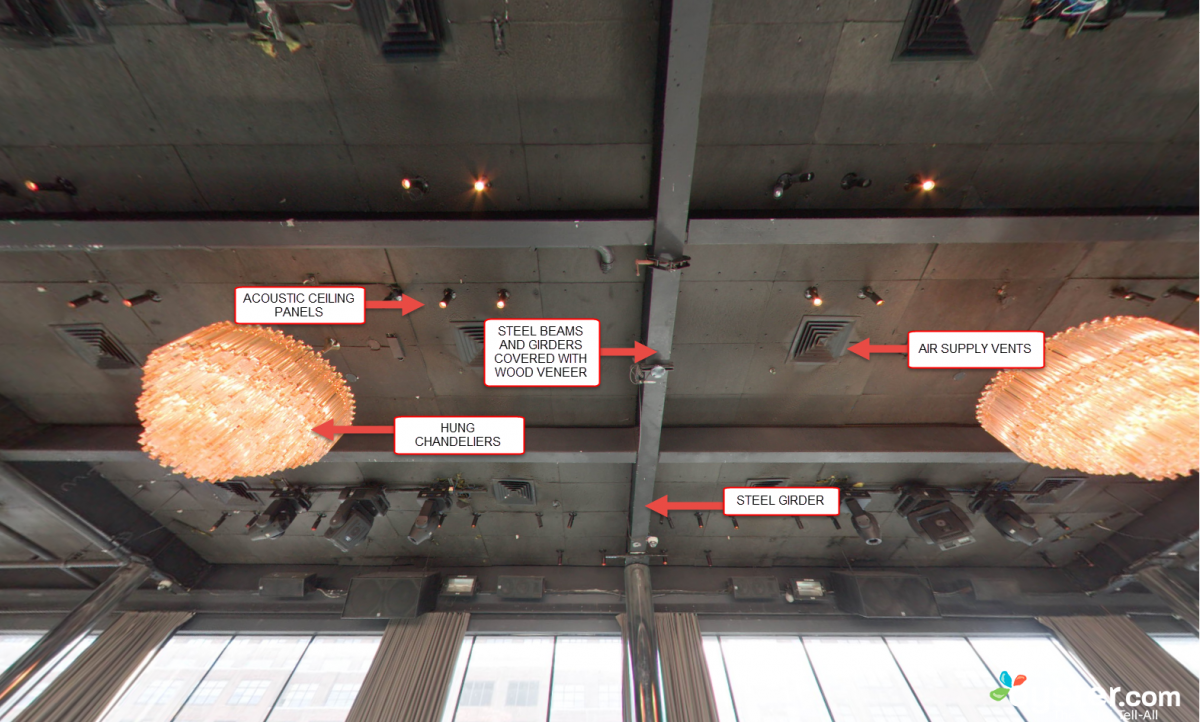

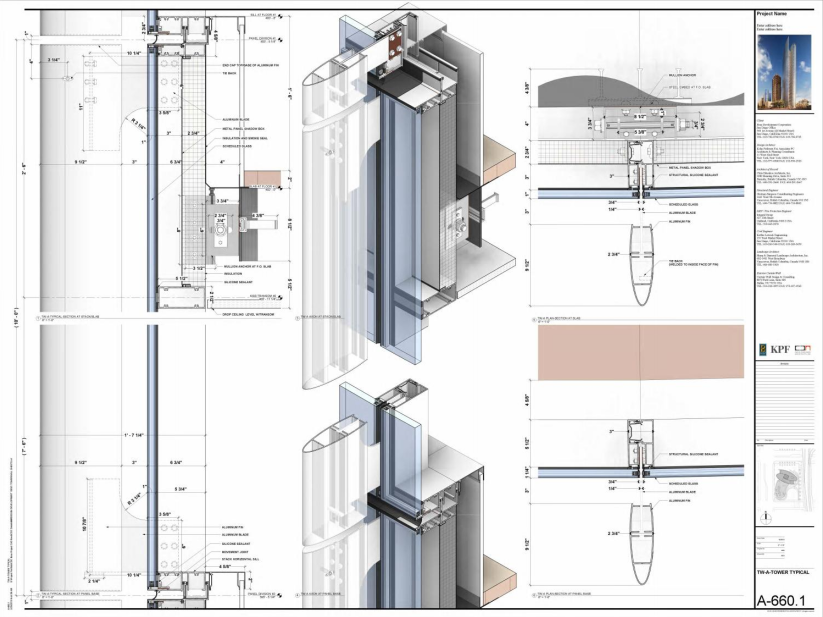

Reflected Ceiling Details and Information

Stainless Steel Paneling and Curtain Wall Connections

After our research we noticed a few corrections we should make:

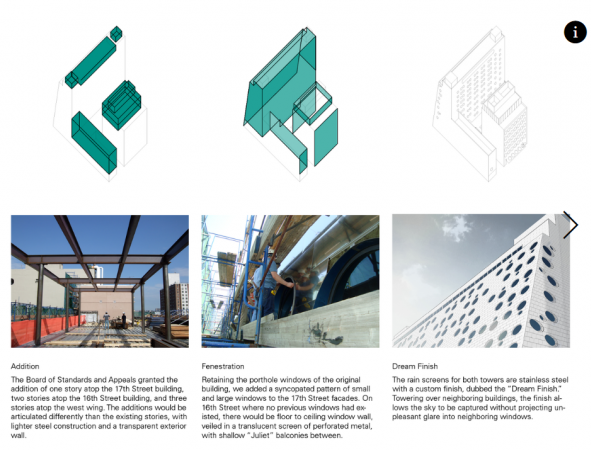

* Head architect : Frank Fusaro Jacqueline Ho

Frank Fusaro is only the partner and the company is Handel Architects.

Her project website is:

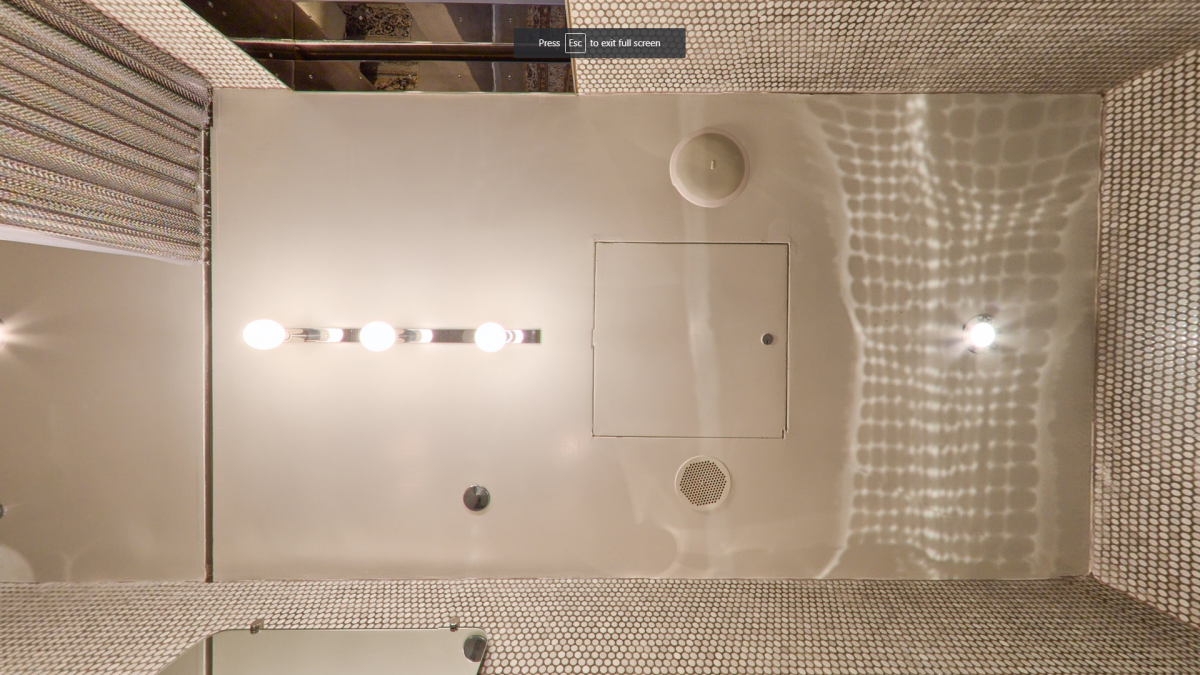

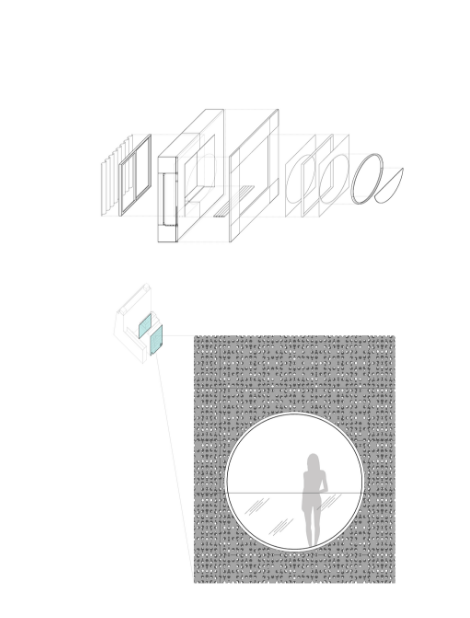

- The pool looks like this:

- And if you’re interested what it’s like to stay in one of these rooms in the hotel it would look like this:

Click here to take a virtual tour of the room!

Stainless Steel Paneling

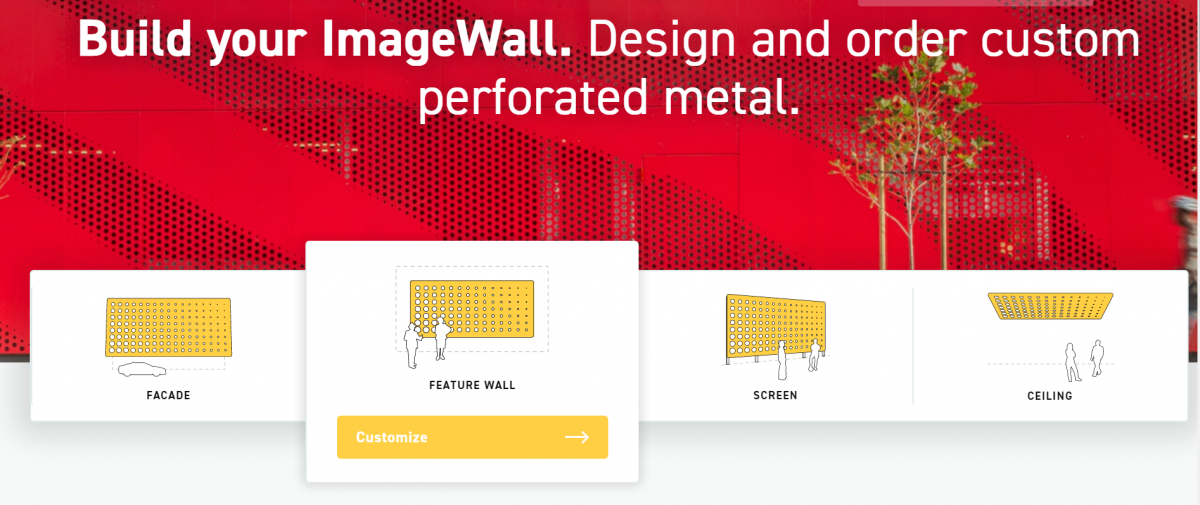

The dream hotel uses a perforated aluminum paneling system developed by Zahner called ZIRA™. Zahner has developed systems like Zira, Imagewall, inverted seam, and ZEPPS to combat the difficulties of complex steel geometry many buildings require. It allows architects to develop useful and quick prefabricated materials for buildings that need steel systems.

Zahner is very knowledgeable in the use of many materials and espcially zinc, steel, and aluminum.

Stainless Steel

According to Zahner, Stainless is:

“Stainless steels are naturally reflective. Oxidation does not develop very rapidly and the surface remains very smooth. Having a tight, smooth surface enhances the corrosion resistance of stainless steel. The more the surface is polished, the better the long-term performance.

During the production of stainless steels, the mill surface of the thick plate is cleaned of scale using strong acids. This process, known as pickling, dissolves the heavy oxides and free iron carbides that rise to the surface of the hot plate.

Further reduction of the stainless-steel thickness is performed on cold semi-polished rolls. These rolls impart a smooth, reflective sheen on the surface of the metal… Annealing the stainless steel in a controlled atmosphere will create a mirrorlike surface known as Bright Annealed…The reflective character of the various stainless-steel finishes can be divided into three categories … The Reflective Finishes can be described as those that reflect light similar to a mirror.

Disturbing the even reflective surfaces with minute surface fractures or indentations, which scatter the reflected light slightly, produces the Diffused Reflective Finishes. Because these finishes are typically applied over the Reflective Finishes, they possess a brightness, an almost glowing behavior when in strong light.

The Low Reflective Finishes possess a dull reflection. Light is effectively scattered by the rough surface. and these surfaces appear flat in most light.

Because of its chrome content stainless steel reflects 49 percent of the visible wavelength of light. It is much more heavily weighted toward the blue wavelength and captures well the tone of the sky. On cloudy days, stainless steel will appear with very little luster. This is due in part to the scattering effect of the clouds, which reduces the blue segment of the wavelength of light reaching the stainless-steel surface.

Because of the specular nature of stainless steel surfaces, slight variations in plane can affect the relative color. Moving around the surface changes the angle of view from one surface of a plate or panel relative to another. The more direct the reflection, the lighter the color. The panel that is slightly askew will appear darker in strong light. A stainless-steel surface can look dark from one angle of view, then light in color from a different angle of view. The difference can be only a few degrees out of plane. This faceted reflection is common in stainless steel thin-plate surfaces. This is also why “oil-canning” tendencies are greater in reflective metals such as stainless steel. The relative high and low points in a stainless-steel surface reflect light back to the viewer at varying angles, which create apparent visual distortions in the surface.

When fabricated and installed correctly, the reflection is not distorted by the undulating surface. Light washes over the diffused reflective surface in straight lines. The mirror reflective surfaces show straight lines as straight images and not curved images.”

———————————————————————————

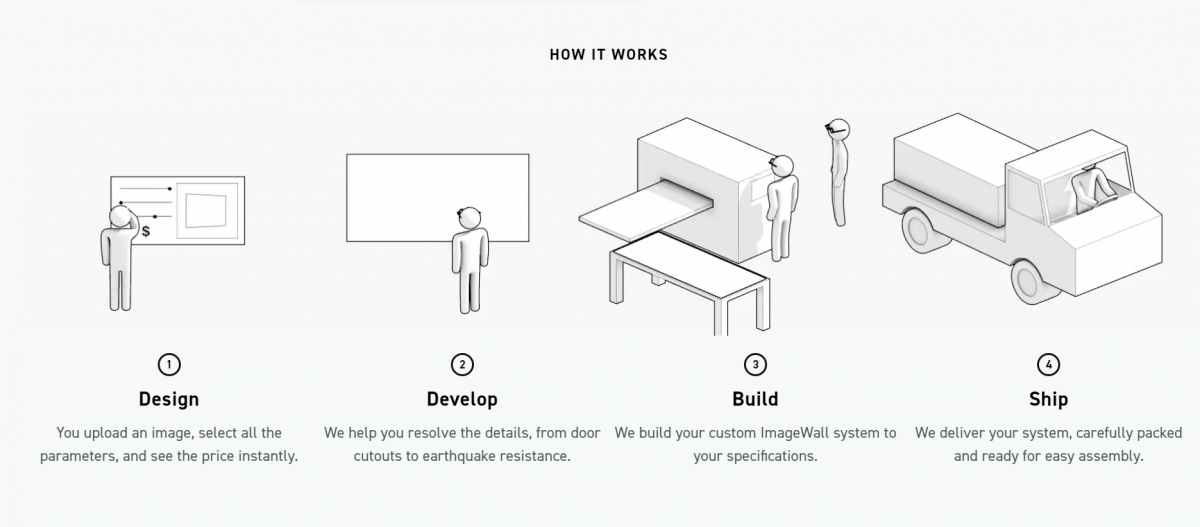

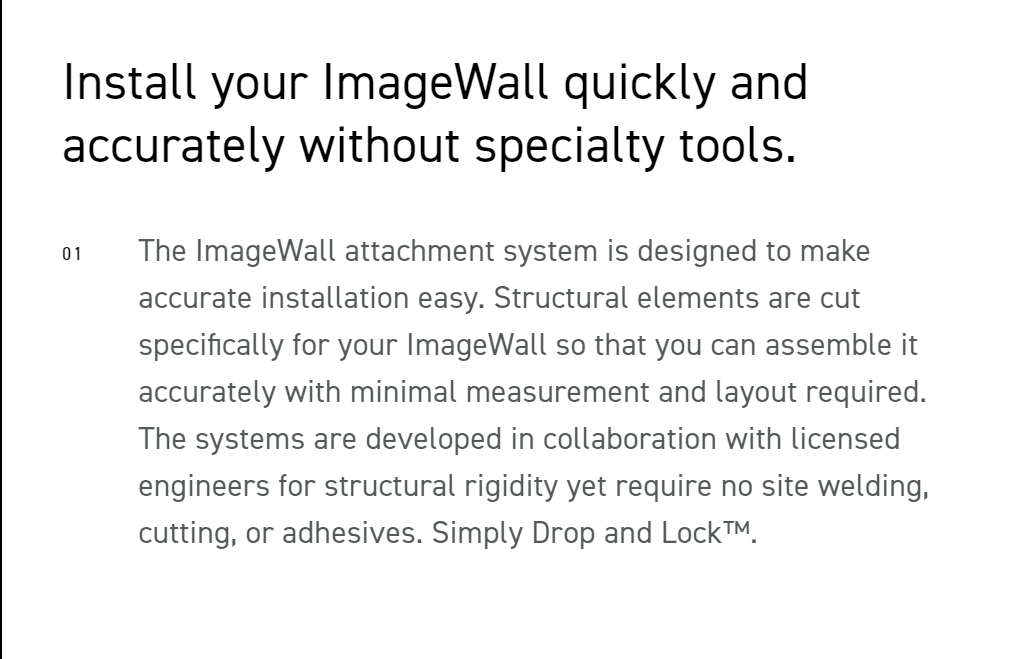

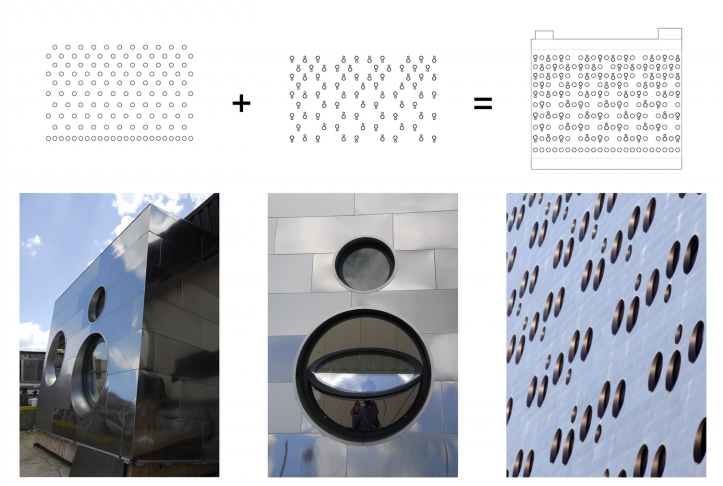

The Zira technlogy is an advanced version of the imagewall technlogy used by Zahner. They even have an app that anyone can order a metal panel with the image they desire and is prefabricated and shipped to you. Below is some images explaining the process and how it is connected.”

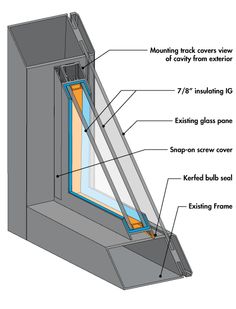

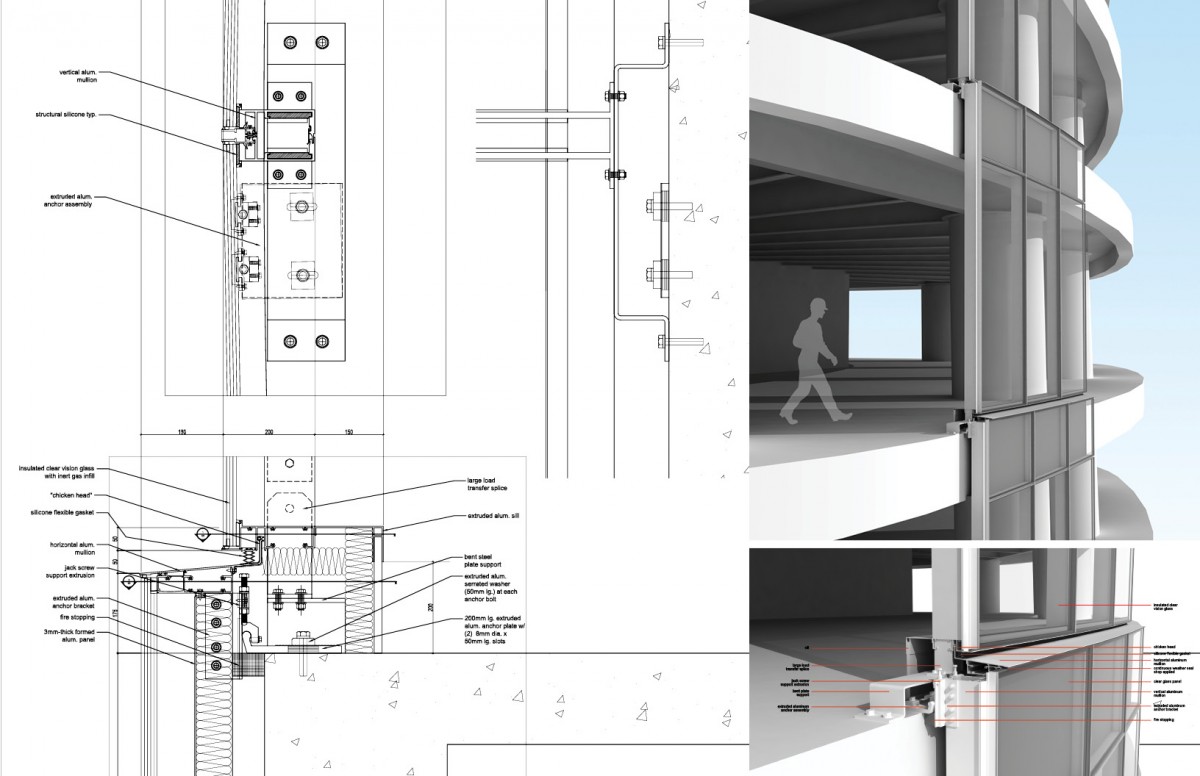

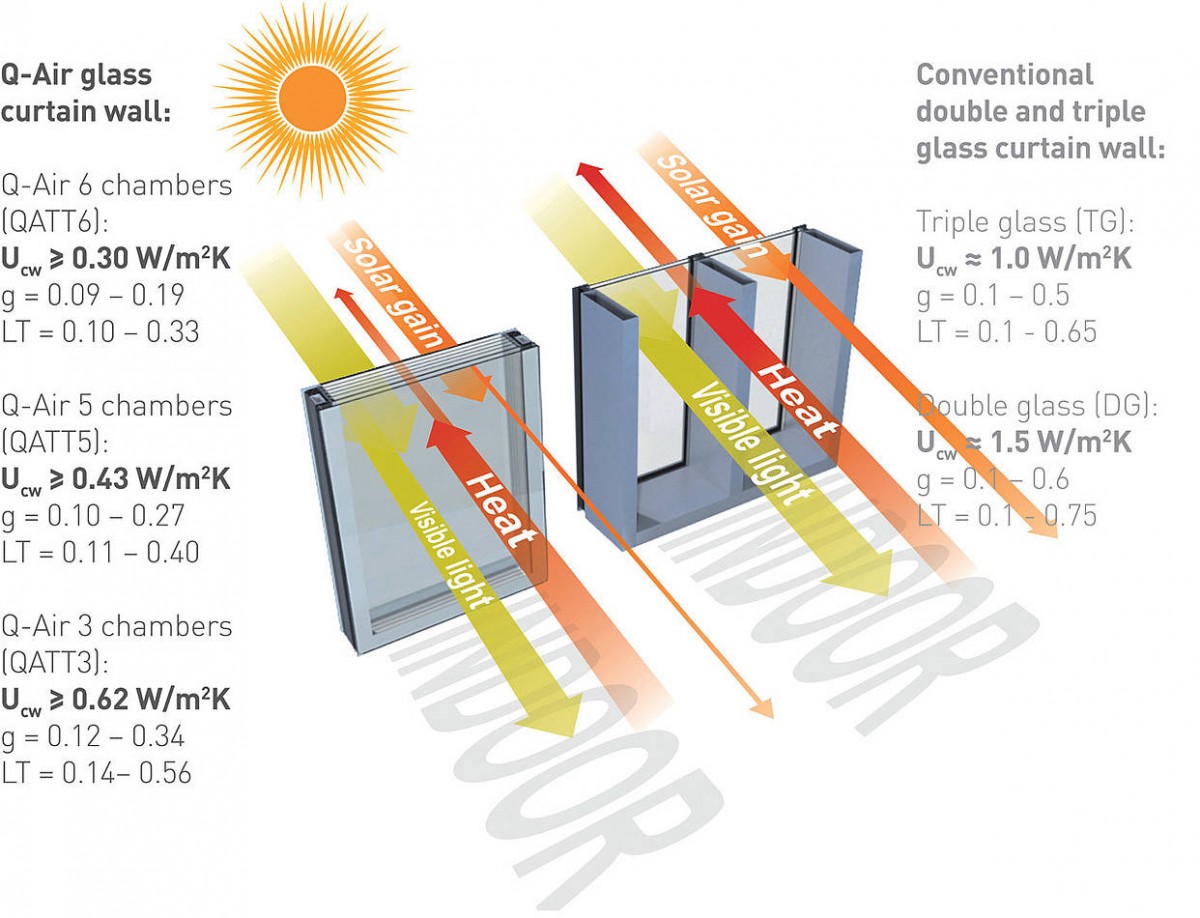

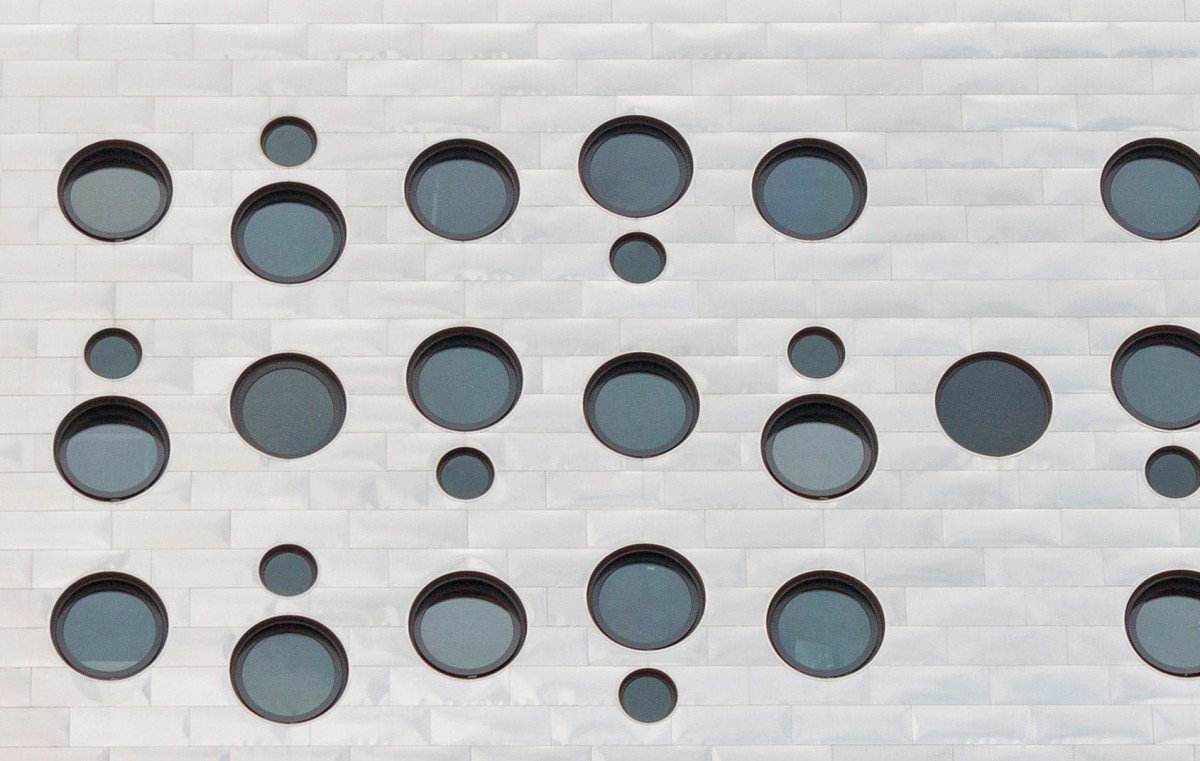

We also noticed that in the Dream Hotel, behind the aluminum paneling there is a glass curtain wall beneath the skin of the building. On other sides of the building is another type of facade system that might be a dry wall that is blanketed by a steel panel with portholes cut out. On our investigation we found some images that might give us that kind of information.

We’ve also found more research on the construction and development of this building.

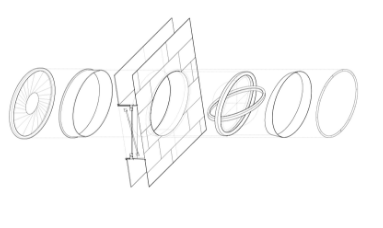

According to the managing architect this is the porthole design that is in the building.

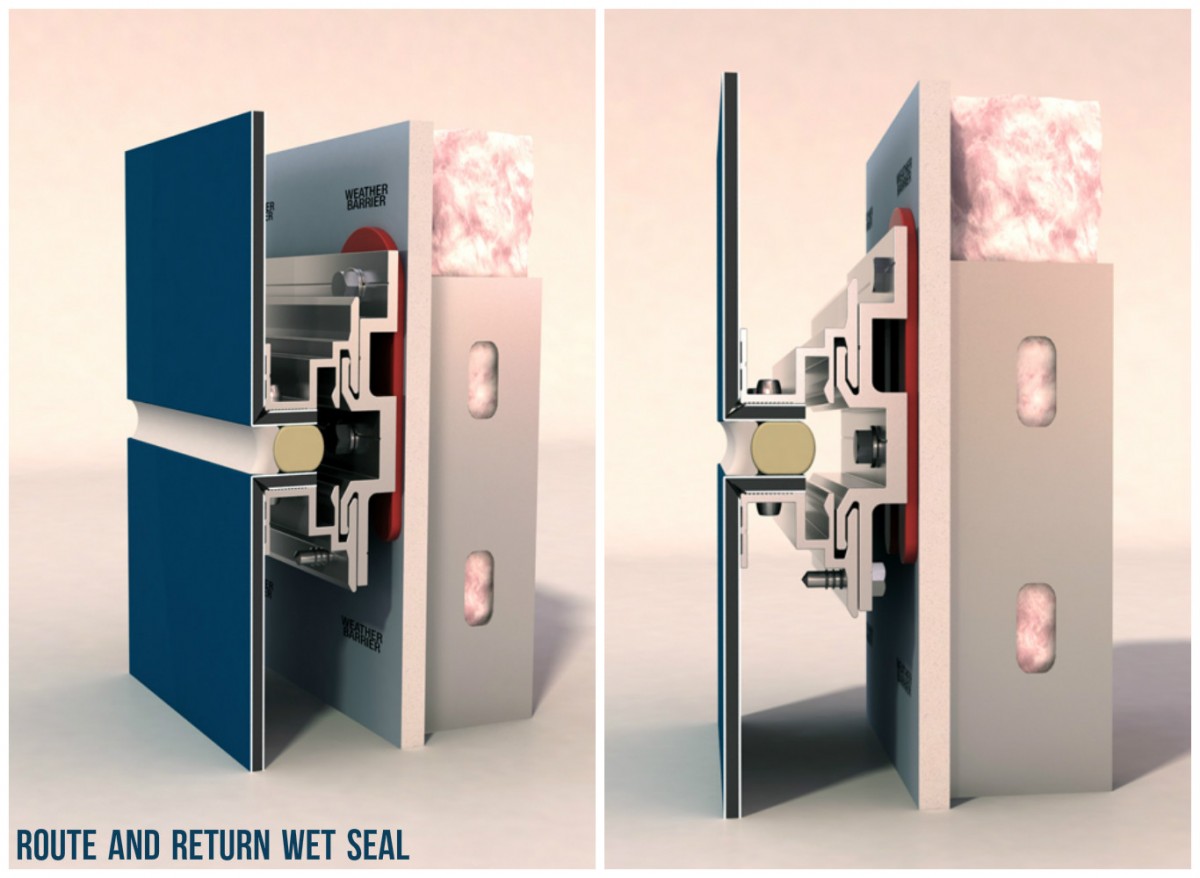

For the sill of the windows it might look like this.

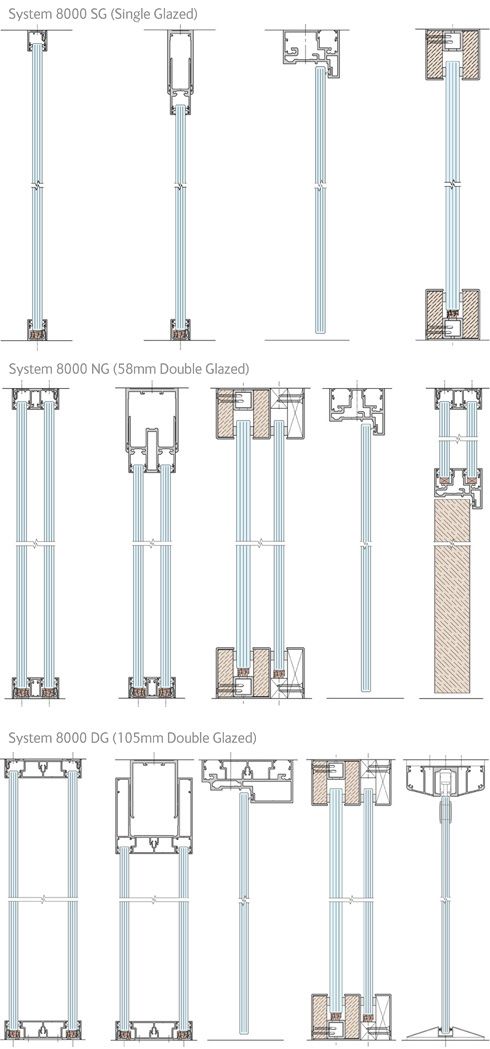

Aluminum Panel Connections

We’ve also found some information on different systems of aluminum panel connections, in our building it is a rain screen aluminum panel that allows water in, however these are other methods of having aluminum panels.

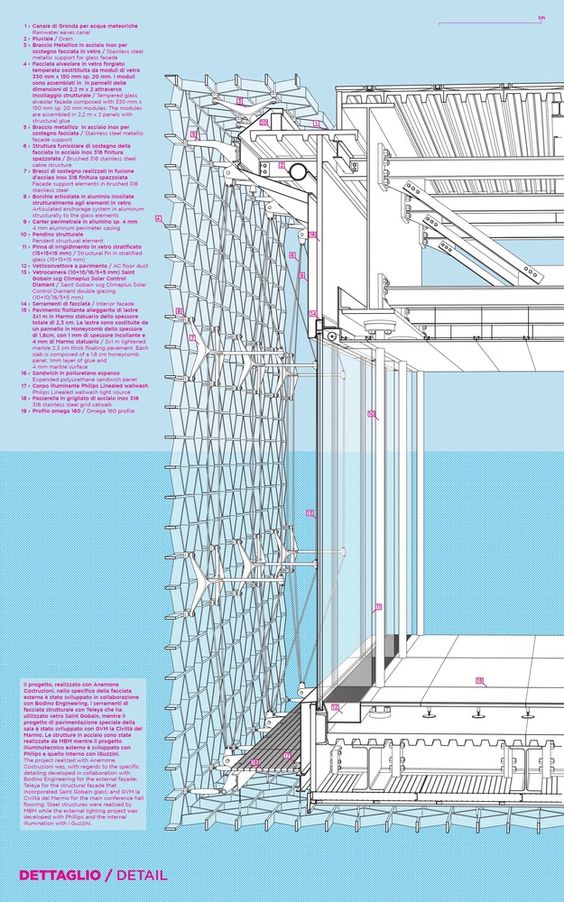

Facade Detail Information

What is a facade?

Dream Downtown Hotel hired Zahner steel engineers to design stainless steel paneling with circular portholes cut with a specific patterns. The facade is constructed out of a Stainless steel perforated sheet metal that is overlayed and held in place in front of the windows and mullions on the facade. This kind of metal patterned facade is Zahner’s technlogy called Image-Wall that can use parameters to determine the patterned steel facade.

The entrance to the Dream hotel also has cantilevered canopy that filters light and has a glass inset which

The use of stainless steel paneling for the skin of the building allows for the building to blend naturally and almost disappear. However with different angles the facade seemingly changes color, from light to dark with its reflective attributes.

Links to original photographs and information. All copyrighted images belongs to A. Zahner, Dream Hotels LLC and Handel Architects.

Building Heights

Case Study Assignment 1

The Dream Hotel

Welcome to our project of our case study analysis of the Dream Hotel located at 355 W 16th St in Chelsea. The building has its historical roots as well as modern renovations where our team members, Tom, Mikayla, Yocelyn, and Lisa will be analyzing the structural details of the building with the guidance of Professor Paul King at City Tech. These studies will focus on the building technlogy of Dream Hotel, we will be learning how to research a building and to study every component via the tool of Revit and our understanding of architecture so far.

Please stay tuned for future posts and feel free to leave us a comment or contact us directly.

-Tom