A City Tech OpenLab ePortfolio

____________________________________________________________________________________

112 Shepherd Ave, Brooklyn, NY 11208

Cell:(718) 663-1142 Email: Jeoffreyforde@yahoo.com

Objective: to obtain a position as a Drafter / Scenic Carpenter / Painter

SUMMARY OF QUALIFICATIONS

Skills: Microsoft Office, Power Point, Stagehand and Basic Rigging, Scenic Construction, Auto Cad, Avid Media Composer, Vector Works, Programming / Python, Basics of video and Watchout.

Education: Beach Channel High School, Franklin Career Institute

New York City College of Technology Spring 2016 – present

Bachelor Degree Fall 2021

Experience: STUDENT CREW MEMBER, NEW YORK CITY COLLEGE OF TECHNOLOGY

Load-in and set up truss, rigging, constructed platforms, painted and built scenery.

Work History:

Shop Dog NYC

Brooklyn, NY

Carpenter/ Painter (2/2020 – current)

Sets & Effects

1239 Dekalb Ave

Carpenter Apprentice / Painter (6/2019 – current)

UPS

1040 Foster Ave, Brooklyn, New York

Pre – Loader (5/4/2018 – 6/2019)

Food Kick

Brooklyn, New York

(3/2018 – 5/2018)

Duties: preparing deliveries

MERCY HOME CARE

Brooklyn, New York

Warehouse Worker (3/9/2015- 3/2018)

Salmagundi Club

47 Fifth Avenue, New York, NY 10003

Part time Bartender

The Metropolitan Museum of Art Warehouse (Tuttle Agency)

Middle Village, Queens

Fall Seasonal (2011- 2017)

Job duties and Responsibilities:

Shipping:

• Prepare orders for shipment in accordance with the pick ticket and customer requirements.

• Pick and ship in accordance with packaging guidelines and accepted methods.

Receiving:

•Receive and unload incoming materials and compare information on packing slips with purchase orders to verify accuracy of shipment.

• Sort, count, package, label and unpack inventory that is received.

• Inspect shipments for damages, loss or defects.

MEDICAL AT WINSTON

Manhattan, New York

Temporary Phlebotomist

WINSTON STAFFING SERVICE

Westbury, NY 11590

516-333-3222

(8/3/2014 – 2016)

Duties: Temp phlebotomist

QUALITY PROTECTION AGENCY

New York, New York

Front Desk Security

Security guard (4/29/2013- 3/2015)

EASTERN SECURITY

New York, New York

Security Guard (10/ 2010 – 05/ 2013)

RITECARE MEDICAL

Brooklyn, NY

WAREHOUSE TECHNICIAN (6/10/2008- 10/1/2009)

References Available Upon Request

JOINERY AND MOULDING

1. DESCRIPTION

The first day of class back in person was a day filled with many emotions and from listening to some of my classmates presentations today I now know I’m not the only one who thought so. For most it was the first day back on campus in a year or close to a year.

I fully understood the problem correctly on my first try. I had to make some moldings and put together joints I have made before. The only problem was I haven’t picked up a tool in a year or longer. At some point I found myself struggling to make accurate measurements which frustrated me.

2. ANALYSIS / ANALOGY

A real world situation that are like this problem is working in a scenery shop. In the real world situation things would be different from our problem is I would not be rusty if I if was back working in the shop five days a week. Like anything in life the more you do it the better you get at it.

3. APPLICATION

From this assignment I learned that even Though I have not been in the shop I In over a year I’m still comfortable using all the saws including the band saw which I have not used since 2018. I enjoyed using the saw to make half laps. I will take what I learned and will use that that experience in the real world and continue to try different joinery. After completing the two frames I was not happy with the outcome but I understand that my cuts got better as I went on and slowly got a little bit back into rhythm.

JOINERY AND MOULDING

The first day of class back in person was a day filled with many emotions and from listening to some of my classmates presentations today I now know I’m not the only one who thought so. For most it was the first day back on campus in a year or close to a year.

I fully understood the problem correctly on my first try. I had to make some moldings and put together joints such as mitre butt joint, pocket screw, mortise and tenon and half lap joinery like I have made before. The only problem was I haven’t picked up a tool in a year or longer. At some point I found myself struggling to make accurate measurements which frustrated me. I enjoyed having the opportunity to use the mort – terson press to drill holes and making biscuit joinery.

A real world situation that are like this problem is working in a scenery shop. In the real world situation things would be different from our problem is I would not be rusty if I if was back working in the shop five days a week. Like anything in life the more you do it the better you get at it.

Description

The Solo Platform assignment was a assignment from early in the semester and was due March 3rd. At the time of completion I did not fully understand the problem correctly on the first try and re reading this assignment now I would have done much better now.After drafting so much for my culmination project and reading the solo platform assignment I did learn something’s that made me rethink the problem. My overall main issue is being rusty. Before this year I have not drafted since 2019 and had to go back to the basics look back at my notes from Drafting I, Drafting II and Cad Drawing to remember certain commands and get use to drafting in autocad again. Getting familiar with autocad again dominated my work process.

Analysis/ Analogy

In a real world situation if a student/ recent grad or years after graduating and you take up drafting again own your own or for work you may be rusty at first.

Application

From this assignment I remembered how to draw multiple flats in autocad, how to do elevations. I will apply what I learned in the real world because post graduation I would like to become a freelance drafter as one of my jobs and gain more drafting experience in the real world.

Description

The Load in Lab was my last day in person for this class and it was a good learning experience. For the load in lab the class had to put together two flats and create a list of tools to use without taking another trip into the tool shed. I understood the problem correctly on the first try but we did not plan out the steps on how we would do the load in. The next time I do a project like this I would rethink the problem and be better prepared. Instead of selecting all the nails from the tool shed I would measure the thickness of the two flats and from that I would know what size nails to use. This alone is one of the most important things I learned that class. I would also know that from looking at the flats I would know that I don’t need to bring hex bolts, washers and nuts for the flats with no holes. One part that dominated our work and time was marking/ measuring the floor. This is a technique that I have first learned in advanced scenery and have done twice in technical direction class so I would like to have more experience doing this so I could know how to do this own my own and only taking no more than ten minutes to complete on my own. Putting together two flats is easy but measuring the floor was not. An idea that I started with that later discarded was not planning ahead because it takes longer to plan was you work.

Analysis/ Analogy

A real – world situation that is like this problem is a real – world load in. In a real world situation professor would not be there to help us.During the class lab Professor McCullough was there to help guide us which won’t happen in the real world and it would be a total difference experience. A problem missing from class that would be present in the real world is we would be in a different setting where we might not know where everything is, maybe a cramped fright elevator and there would be other people around for example a lighting crew.

Application

From the load in lab I learned that the steps are to mark the floor with chalk, assemble the walls, stand up and then attach. I already knew communication is key working with a crew but In each lab I was constantly reminded the importance communication. For example for the load in lab at one point there was three of us holding one flat when I was already holding the flat which is light enough for me to hold by myself. I knew this and knew the rest of the group could be doing other things while I held it but I didn’t want to come off as being bossy so I just kept my mouth shut. Same thing happened in another lab when we were putting together a platform. I knew to start at the bottom and work my way up. The rest of the group members were crewing in the bolts together at different points. Some people were the the bottom, one person in the middle and so on but I didn’t want to say anything. In the next real world experience I expect to have that might be related to this activity is in the real world I will definitely be doing load in, putting together flats, platforms, marking the floor with chalk, working with crews and having to plan things ahead before putting them together.

Description

The Solo Platform assignment was a assignment from early in the semester and was due March 3rd. At the time of completion I did not fully understand the problem correctly on the first try and re reading this assignment now I would have done much better now. After drafting so much for my culmination project and reading the solo platform assignment I did learn something’s that made me rethink the problem. My overall main issue is being rusty. Before this year I have not drafted since 2019 and had to go back to the basics look back at my notes from Drafting I, Drafting II and Cad Drawing to remember certain commands and get use to drafting in autocad again. Getting familiar with autocad again dominated my work process.

Analysis/ Analogy

In a real world situation if a student/ recent grad or years after graduating and you take up drafting again own your own or for work you may be rusty at first.

Application

From this assignment I remembered how to draw multiple flats in autocad, how to do elevations. I will apply what I learned in the real world because post graduation I would like to become a freelance drafter as one of my jobs and gain more drafting experience in the real world.

Jeoffrey Forde

Culmination Reflection

Culmination Section Spring 2021

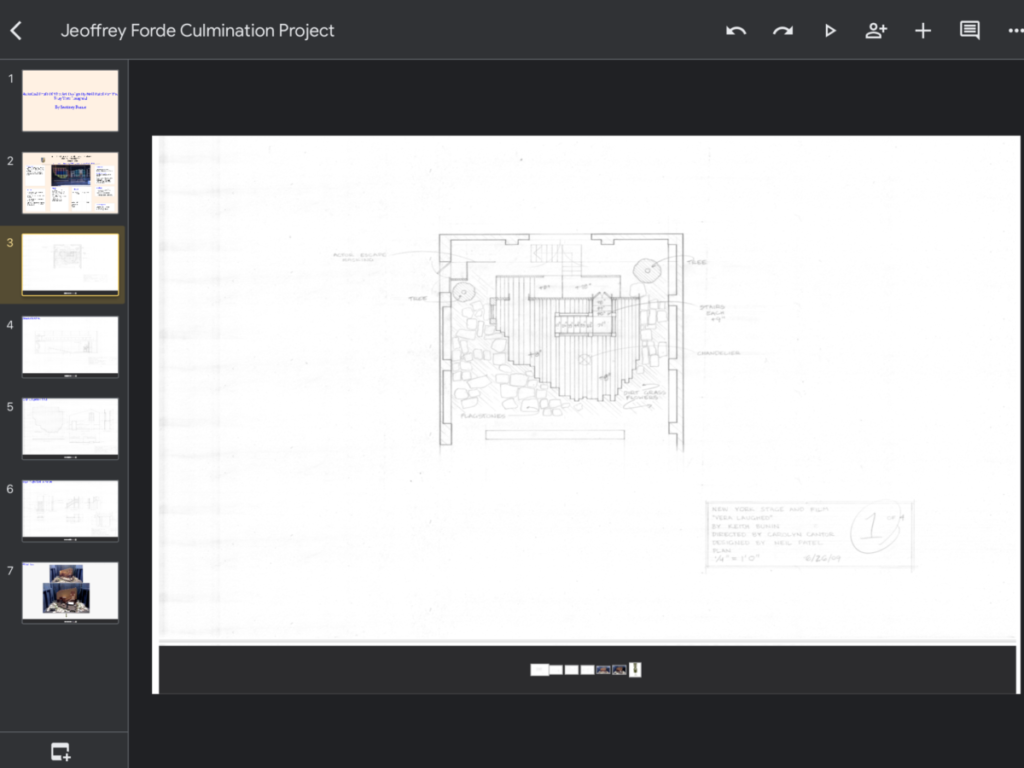

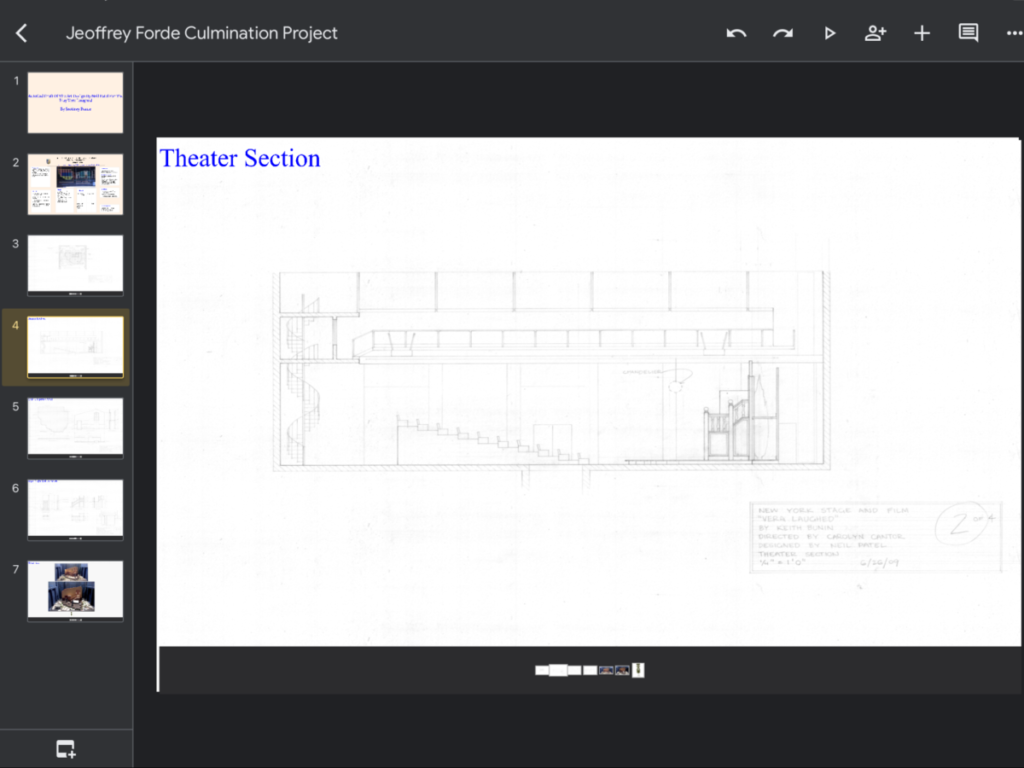

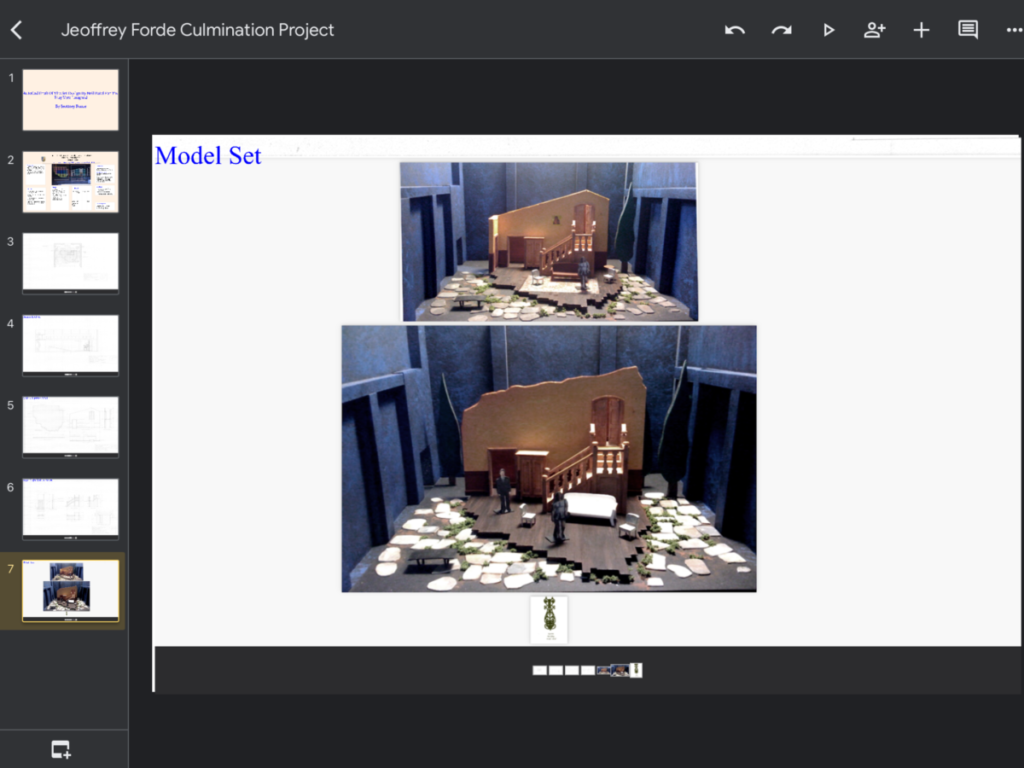

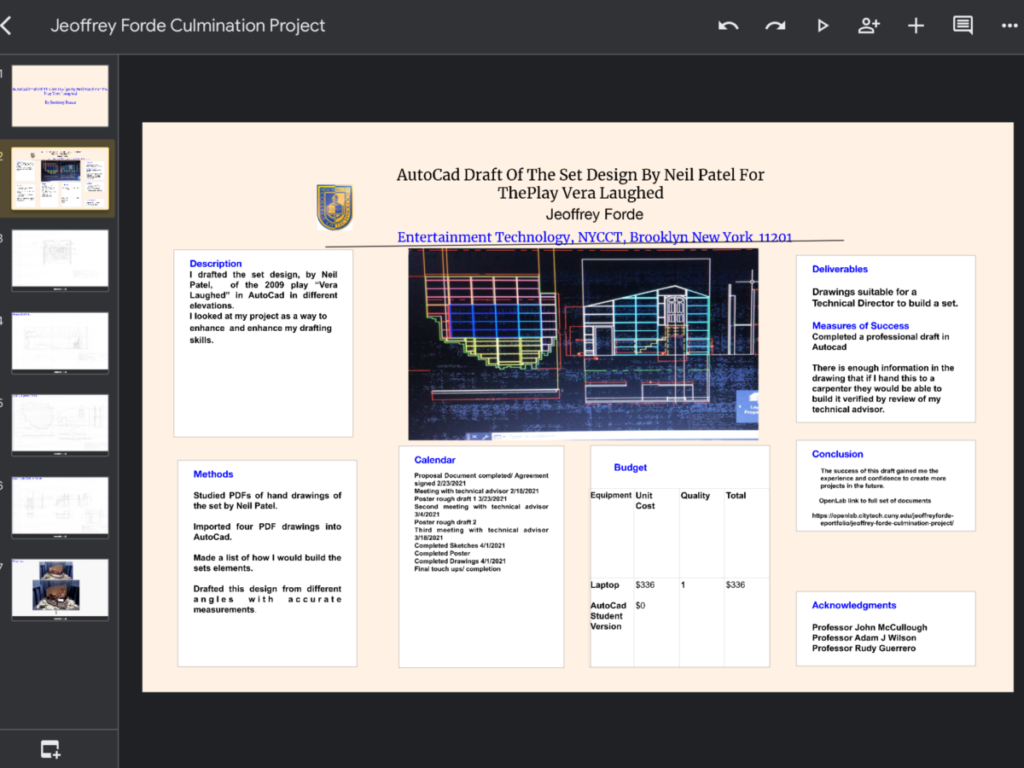

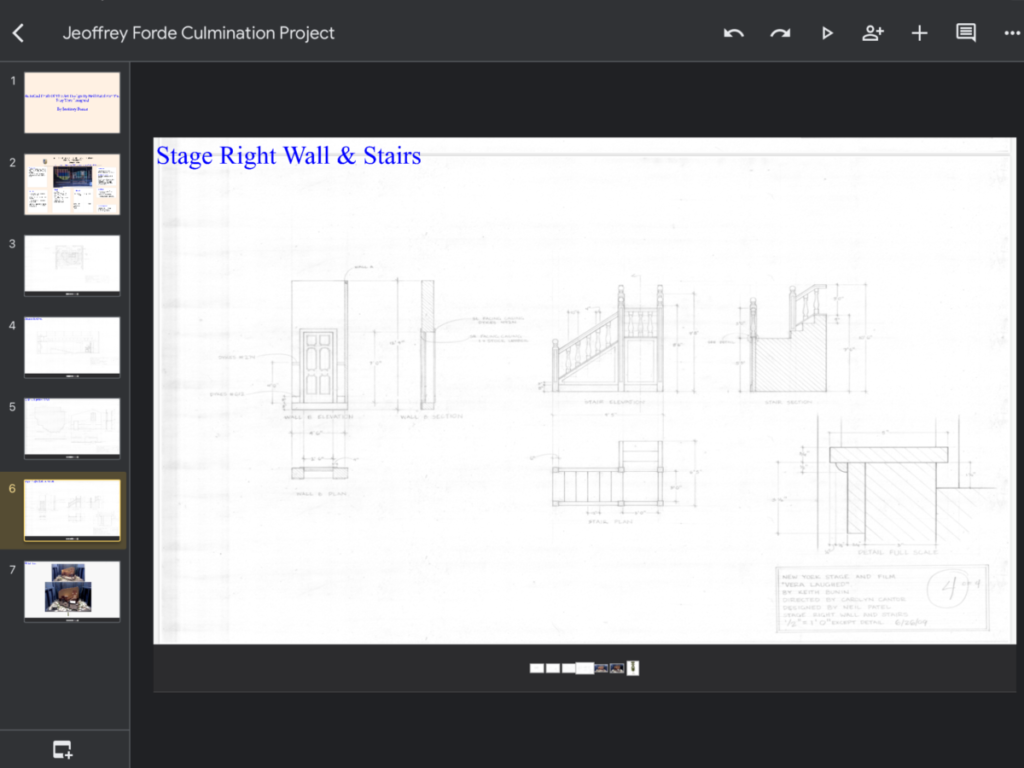

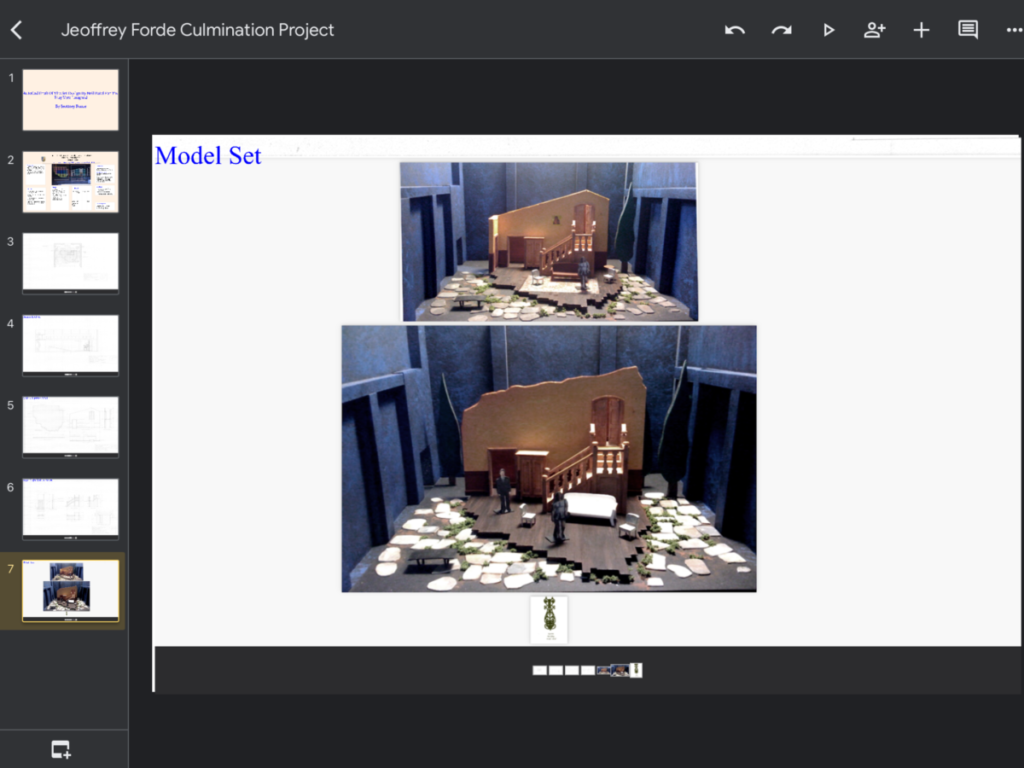

Drafting the set from the play “ Vera Laughed” for my culmination project has been filled with many obstacles . Unlike all the classes I’ve taken in the past three semesters virtually since the pandemic started the culmination project is the only one that’s had a negative effect on me. For my culmination project I decided to do a AutoCad draft. Early on it took me a couple hours to shake off the rust for I have not used AutoCad since the Fall of 2018. What makes this class stand out from all the rest of my classes in the past three semesters is that I needed a lot of help with this project and because all of my classes are majority online I could not receive the help I needed right away. I had to write several emails and wait for reply’s which delayed my process in a big way. Another obstacle I had to overcome was how to build the set. In CAD Drawing, Drafting I, and Drafting II I mostly just drew objects without always knowing how to actually build them.

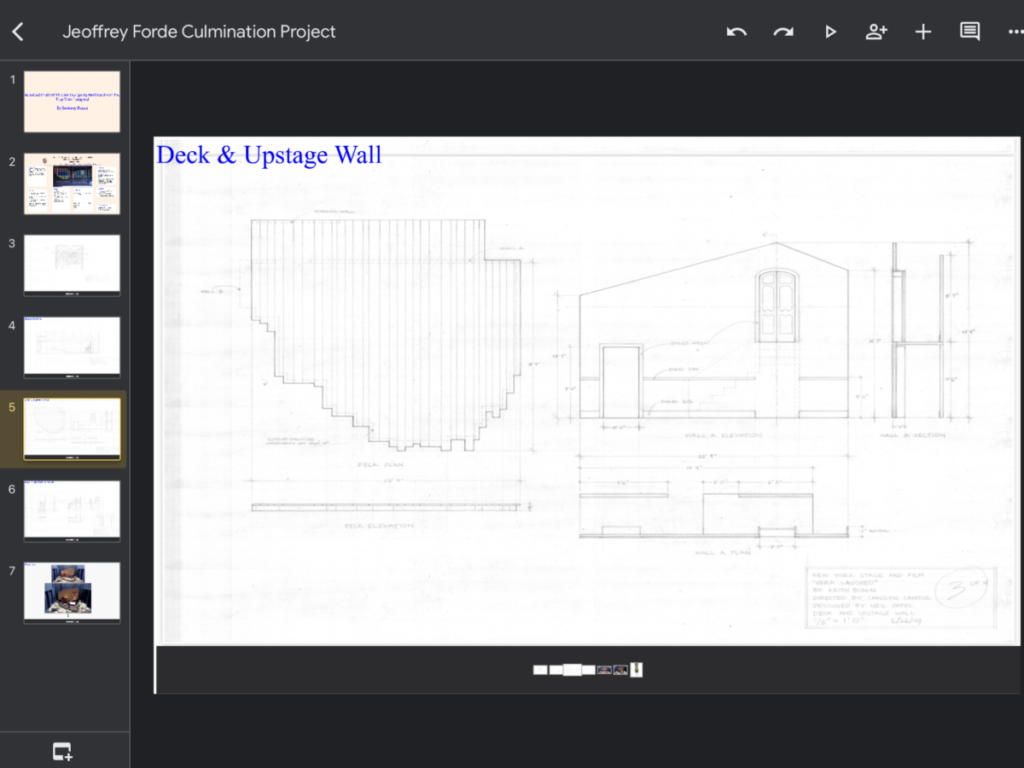

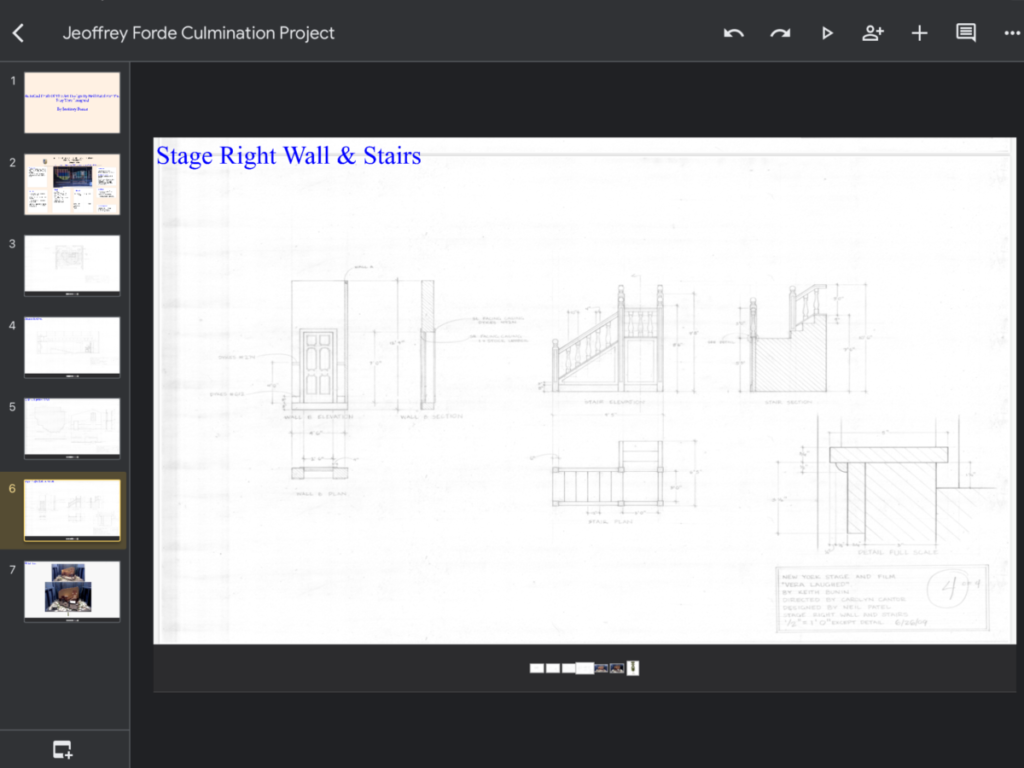

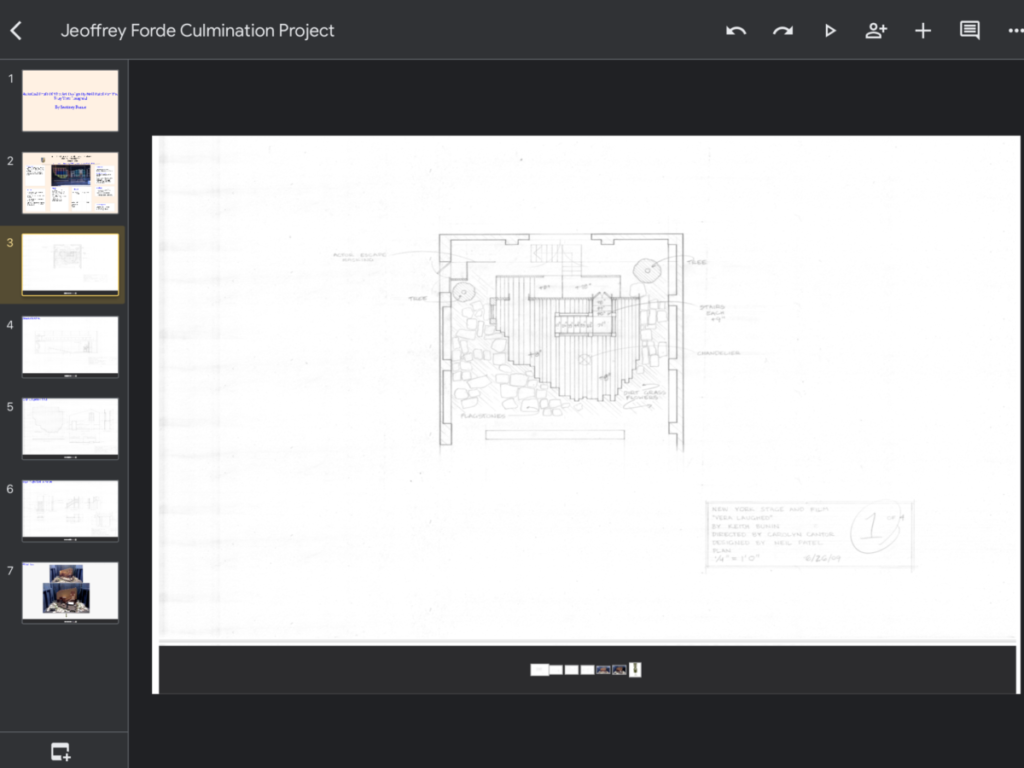

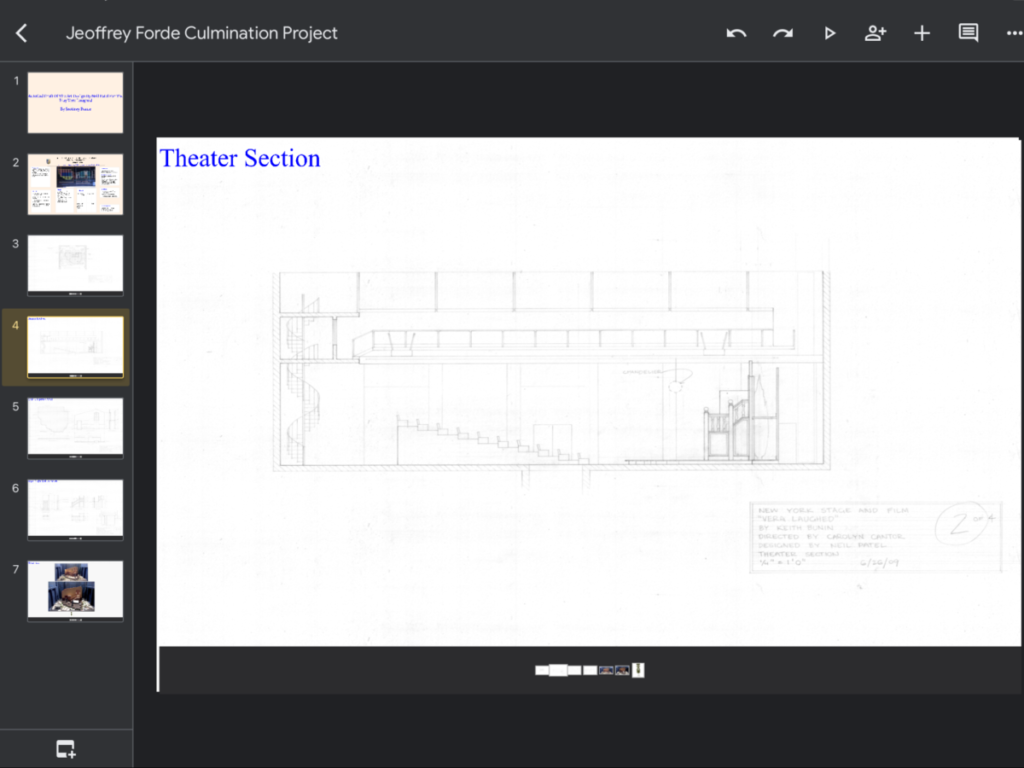

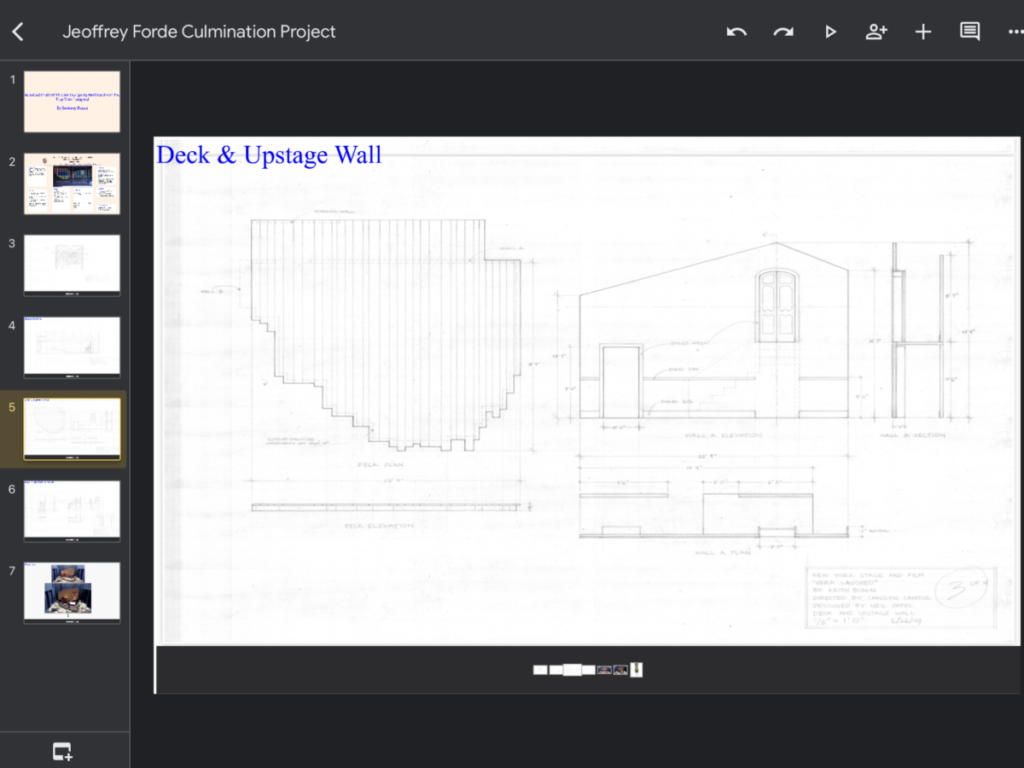

One thing I learned early on from this project is I will have a arduous time drawing something if I don’t know how I’m going to build it. I had to stop drafting and plan out how I’m going to build the elements which is something I didn’t have to think about in the past. Vera Laughed set contains four elements. The deck, flats, stairs, and rocks. My task was thinking about how I would build each element. For me this was a very daunting task that discouraged me and at times made me think to myself why I choose to do this project in the first place. I did like learning about the different ways to build actors stairs and some other things I learned from reading the Stock Scenery Construction Handbook. One of the biggest things I’ve learned from this project is the importance of using layers. The most challenging element to build and draft was the deck. Deciding how to build the deck took me days to figure out. How will I support the weight? What type of floor to use? What I came up with is using four by eight platform stock covered with Luan. On top of the Luan is wooden strips individually cut. After I figured out how I would build the deck it was now time to draft the deck.

The same way It took me days to figure out how I would build the deck I spent more time drafting the deck than any thing else in the entire project. I really had a hard time understanding the platform decking in the beginning. I wasn’t until I finally began to understood the framing which took longer than usual that my love for drafting slowing began to return. Instructions on how to build the deck required several drawings in several layers. Some of the drawings include platform layout, individual platform lids, and each individual platform has its own layer.

In conclusion, I would have liked to complete my culmination project for the last four months it was my number priority unfortunately I could not receive as much help as I liked but I I’m thankful for everything I have learned and I will incorporate these lessons as I increase my education moving forward.