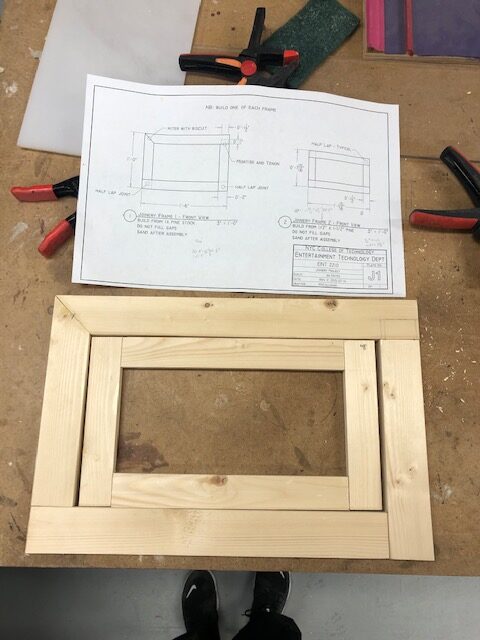

For our Joinery Lab we had to build 2 frames according to the plan shown. Each frame incorporated different joints in order to be put together. These joints included biscuit joints, half lap joints, and mortise in tenon joints.

I had to figure out how I had to cut the wood pieces for each frame, and how I was going to make each joint. The wood for the smaller frame needed to be 1-½” wide and ½” thick. Using 1×6 I needed to make rip cuts with the table saw and plane the wood with the planer. After cross cutting my wood to the desired lengths indicated in the plan, the larger frame required a 45 degree miter cut where a biscuit joint would be inserted. I had issues in which frames were not totally flush, where I sanded a joint too thin, or my widths did not match. I believe measuring might’ve been rushed, and I over cut with the bandsaw, when I could have sanded down my half laps instead.

The tools I learned to use during this lab were the biscuit joiner, and the boring machine (for the mortise). I also learned how to mark wood properly for half lap joints, and the tenon, and how to cut them with the band saw. Sanding these joints down makes them flush, versus cutting off too much with the band saw.

The knowledge of joinery is very useful when making specialty furniture, perhaps for certain props or specialty items. I can definitely see myself building furniture in the near future. Joints are more appealing to the eye when connecting pieces of wood, they also provide more stability and security.