We have a final lecture today. Are you ready for summer II?

Author: Masato R. Nakamura, Eng.Sc.D.

Day17 6/25/2019

Good afternoon,

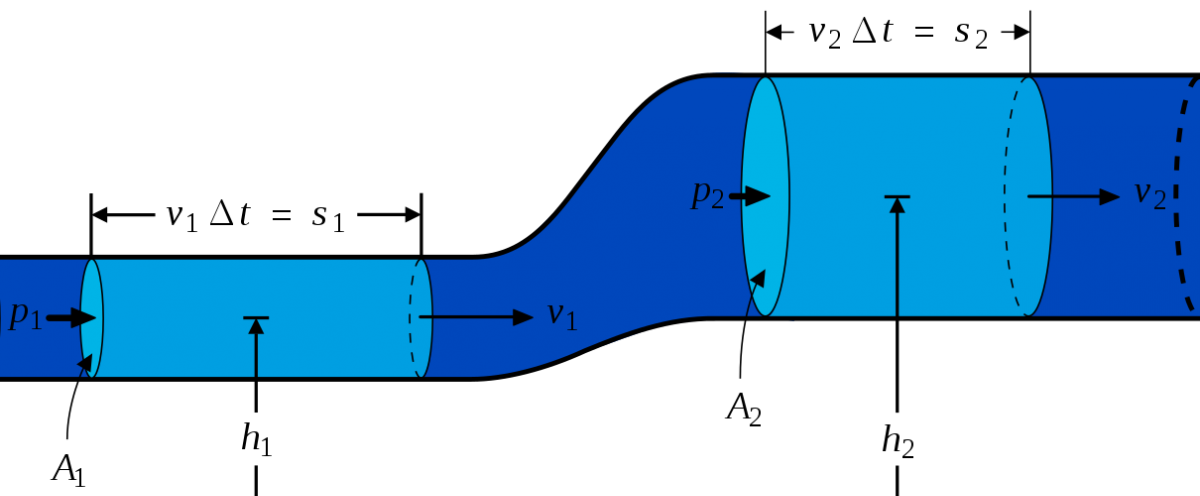

We discussed the conservation of mass yesterday. Today we will discuss the conservation of energy. Do you have any questions about yesterday’s lecture?

EX16 6/24/2019

EX16-1

Air enters a compressor with a density of 1.2 kg/m^3 at a mean velocity of 4m/s in the 6-by-6cm square inlet duct. Air is discharged from the compressor with a mean velocity of 3 m/s in a 5cm diameter circular pipe. Determine the mass flow rate and the density at the outlet.

EX16-2

Same as EX16-1 but paremeters are changed as follows. Calculate the mass flow rate and the density at the outlel:

v1=2m/s

10by10cm duct

v2=1.5m/s

D=6cm

EX16-3

A 20 mm dam pipe forks, one branch being 10 mm in diameter and the other 15 mm in diameter. If the velocity in the 10 mm pipe is 0.3 m/s and that in the 15mm pipe is 0.6 m/s, calculate the rate of flow in cm3/s and velocity in m/s in the 20mm diameter pipe.

Day16 6/24/2019

How was the weekend? Thursday is the last day of this course. Are you ready to complete this course and to be productive in July & Ang?

Day15 6/20/2019

Tomorrow, Friday 6/21, has no class. How will you enjoy the long weekend?

Day14 6/19/2019

Do you have any questions regarding yesterday’s lecture?

Day13 6/18/2019

How was the Project I? Did you enjoy it?

Day12 Project I: Computational Fluid Dynamics (CFD)

Hi Class,

Today we will complete Project I and we don’t have a lecture today. If you have a solidworks software and complete Project I at home, you don’t have to come to school today. However, if you don’t have a solidworks at home, you can come to school and use solidworks in V511 or any other classrooms. Also, you can use the club room and computer lab on the 2nd floor. Please complete CFD simulation and submit simulation result you did by 5pm today by email at mnakamura@citytech.cuny.edu or just put my mailbox if you are on campus.

Project I: using FloExpress in SolidWorks

1. Make a huge tube (15 inches diameter and 60 inches long)

2. In the tube, put the wind turbine you created in the previous EX (around 40 inches from the one side. (Set up the Boundary Condition[BI])

3. Assign a wind at the speed of 15 miles/hour

4. Simulate the wind flow in the tube

5. Take a screen shot&generate a report

6. Send them to me at mnakamura@citytech.cuny.edu by 5pm today.

I have to penalize it any submission after 5pm, so please submit by 5pm today. No excuse. Thank you for your professional attitude.

Dr. Nakamura

Day11 6/14/2019

+

How are you doing?

Day10 6/13/2019

Yesterday, we started the preparation of Computational Fluid Dynamics (CFD). How did you enjoy the solidworks? Today we will do first simple CFD.