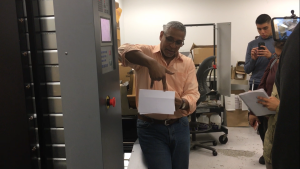

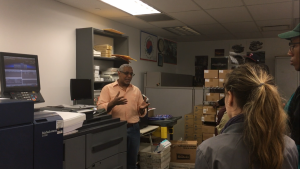

On April 28th, our class went a field trip to the United Federation of Teachers printing facility. The building itself is located on 52 Broadway in the heart of downtown Manhattan. It was hard to find the building because all the buildings that surround UFT building were under construction. When I entered the building, I was greeted by the professor and a few of the students. We waited for a few more minutes after the time the professor instructed us to arrive. At around 9 a.m., we began the tour. Going down the escalators, I didn’t know where the shop was located but I didn’t the printing facility to be under the escalators. It was rather shady from my perspective. We entered the shop and were greeted by the man that runs the shop, Oscar. He then told us his position and that he was working in the printing industry for 16 years and that in 2 years he will retire. He then proceeded to tell us about the many machines needed for printing purposes.

In the facility, there were machines old and new. A grand majority of the machines use digital printing as opposed to traditional printing. One of the first machines he showed us was the KIP C7800. It was the printer, copier and scanner combo. He said they use that machine for current printing jobs. It is a high production color and monochrome wide format printer, scanner, and copier and It weighs 1190 pounds. It is an LED closed toner system and a pretty fast system as well, going to speeds up to 4200 square feet per hour in black and white and 3500 square feet per hour in colors. It features a CMYK dry toner, as well as a paper capacity of 4500 square feet, which equals to three rolls. These machines were located near the entrance of the facility.

Another machine that caught my attention was the Duplo System 3000. It is a collating machine that offers hands-free collation for all types of jobs. Paper is placed in each respective bin and the machine will collate each sheet one at a time. It has different types of stapling, according to which job the stapling it needs. For instance, it can do corner stitch, the most common stitch, the double stitch, which makes a job look like a bound book, and it does saddle stitching. This is when the staple goes in the spine of the paper. The staples are located over the machine. It appears as wire, so it can be configured to whatever job is needed, such as how much paper is in the machine and it measures the size of the staple needed for the sheets.

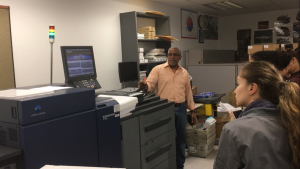

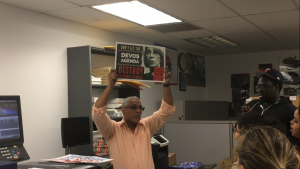

The last machine that we focused on was the Konica Minolta bizhub PRESS C1085/C1100 printer system. These two printers are connected to two other printers and all these printers communicate with each other through the network. They “talk” to each other when a job needs them too. Oscar spoke to us about the texture of the paper and how we are able to feel the text on the paper. It all depends on the whether the sheet is an offset digital sheet versus a copier sheet. Oscar told us that the shop does beta testing and a company was selecting top customers to test their first generation of the current machine they had now back in the day. His shop was one of them, so that made them 1 of 4 in the US to get to test it at the time. At the end of the tour, Oscar gave us a few words of advice for our future in the design industry. He said that all of our classmates are our competition and that we have to engage in conversation and be confident for interviews and always give a firm handshake.he said that we should put together a portfolio of our best works together, and not all of our works. Basically he said quality over quantity. Also, he said we must stay current on what’s new in the world of design.