3D Printing on space

Construction 3D Printer

This project involves In-situ resource utilization into 3D construction on the space, especially on Lunar surface. A dedicated student team is actively working on this project. They are working on supporting NASA’s Artemis mission through the maximization and automation in the usage of local materials including Lunar dust and highland crusts in the construction of space habitats.

Lunar Regolith in Geopolymer

Lunar surface experiences extreme thermal fluctuations in the range of -130 C to +130C. It is essential to maintain mechanical and thermal stability of the space habitats in that extreme environment. This project involves optimization of the mechanical properties of Geopolymer using Lunar regolith.

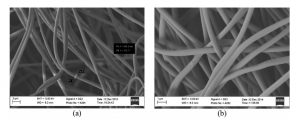

Mechanical and Thermal Properties of Poly Lactic Acid (PLA) Nanofibers :

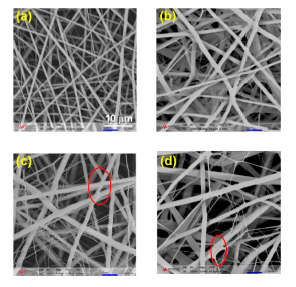

Morphology of PVA/PLA fibers with different weight ratios (a) PLA, (b) L95V5 (c) L90V10 (d) L80V20 ( Collected from Polymers 2018,10,1178)

Project Description: PLA Nanofiber is biodegradable material and useful in biomedical applications. However, PLA nanofibers are weak in mechanical strength. Several efforts are on the way to improve mechanical strength of PLA. With the reinforcement of thermoplastic nanofiber, the goal of this project is to evaluate mechanical strength of PLA using poly-Imide in a form of composite blend.

Mechanical and Thermal Properties of Poly Acrylo Nitrile (PAN) Nanofibers :

Development of Rice Husk Ash for Advanced Polymer Composites:

![]()

Project Description: This project aims at extracting Pure and Pozzolanic Silica from Rice Husk and apply into both brittle and ductile polymer. This silica is expected to increase some mechanical and thermal properties of the base polymers including thermoset and Geopolymer.

Study of Phase Separation and Crystallization of Li-Si glass:

![]()

Project Description: This project concerns the phase separation and crystallization behavior of Lithium Di-silicate glass at a little over stoichiometric Si:Li Ratio (2.33). The objective of this research is to improve the mechanical strength and thermal stability of Lithium- Silicate glass system.

Development of High Temperature Composite Materials:

Project Description: The goal of this project is to develop high composites for railroad tunnel and Subterranean structures.

Effect of Al2O3, ZrO2 and P2O5 on the Crystallinity, Phase Separation and Mechanical Properties of Lithium Di-silicate Glass:

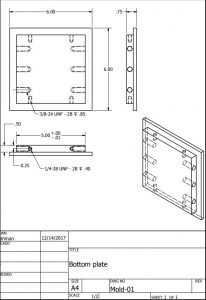

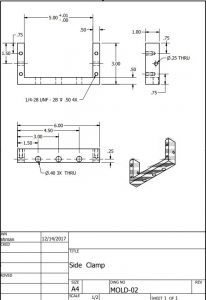

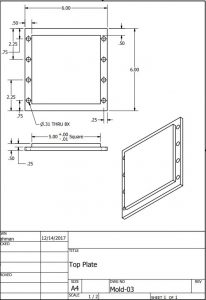

Preparation of Molds for the Advanced Composites:

Experiential Learning Project

Automated filtration on Hydraulic power generation System