The wheel was attached.

-

Recent Posts

Recent Comments

- solarrs on Discussion about Parameter – Image on Board

Archives

Categories

Meta

As we can see, the more that we modify, the more idea would be it. Today, we installed motor and tire along with table. Although we tested several times, we have found that we need to re-adjust

1. Clearance for rotating and tire position so that it reduces wobbling.

2. We need to re-adjust shaft to secure the tire more stable.

This is the prototype 1 for widening top layer of wood. We are expecting to attach a motor with a small toy of tire, rotating under top layer of wood. Here are the samples.

First, we put the double layers to see the different perspectives. Second, we measure the difference of degrees to test out whether from our front view or different angle is shown. From our front view, we can see the picture clearly. When the angles adjust between 35 to 40 degrees, the views change from mid dark to completely dark.

Yesterday, we did some testing and it was getting better. However, we need to improve the table and wiring connection so that when the monitor rotates, it doesn’t hit wires. Here are the pictures that we had yesterday.

Posted in Uncategorized

Here is the sample e-drawing without using SolidWork to open the file. It’s very beautiful and interesting.

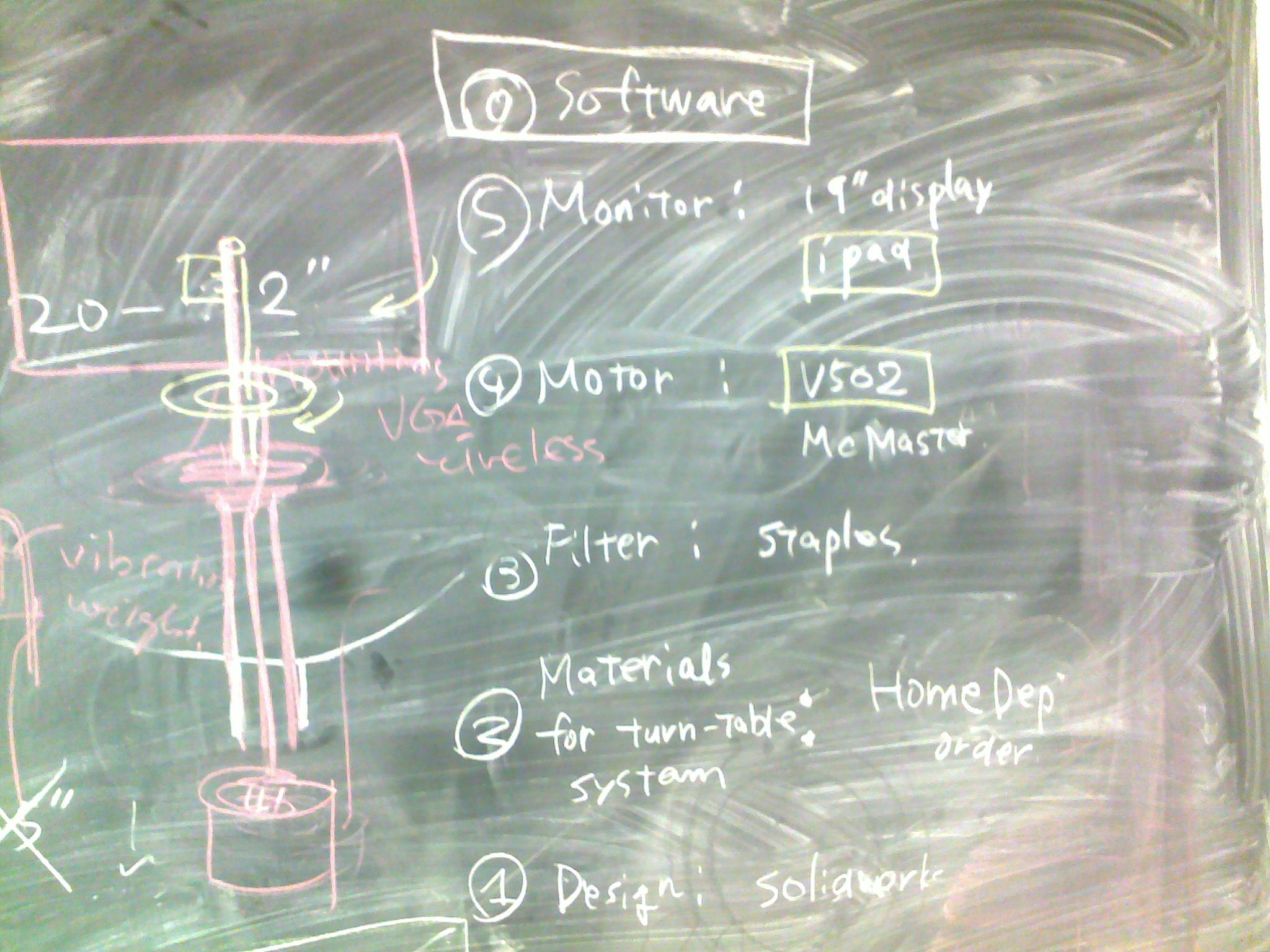

Steps need to be considered

1. Use software to design a project using Solidwork

2. Need materials for turn-table system – through Home Depot

3. Need Filter Protection – 15, 30, or 60 degree.

4. We have already the motor for rotation

5. Need Monitor (LED) from 19″ to 22″.

Here is the design I came off :

Note: We have the LED with stand and a piece of glass/plastic circle to place under the bearing part. However, the concern that I would bring is how we are going to attach the place between the standing ( mounting part ) and the glass/plastic circle. If it rotates faster, then it will fly off.

Today, Professor discussed about 3M screen protector. It refers that we can use the screen protector to illustrate that there are some certain degrees we can look at, not the whole 360 degree. Also, there are some changes on our project.

– Mechanical Engineering

– Manufacturing

– Design

– CAD – computer application

– Simulation

– Analysis ( CFI, Pro F.E. )

Steps have changed

1. Semi-prototyping – ( progress on trying to assemble prototype )

2. Rapid prototyping (3D printer) – Room 508

3. Make a physical model ( real prototype model )

4. Since the 55″ monitor is too big and concerned about weight issue, we have decided that we need to do some experiments first. Then, we can determine later.

Here is the picture on what we discussed today.