I separated the orders by group and what you asked me to get. Lumber is per foot and sheets come in 4×8.

Group: Shannon, Irene, Vin, Marcelo

1×3- Clear 68cents per foot

1/4″ wiggle Luan- they only have 3/8 $45 per 4×8 sheet

3/4″ ply CDX 4×8 38.40 per sheet

1/4″ Luan 4×8 16.64

Group: Mike Jose

1/8″ wiggle Luan- they only have 3/8 4×8 sheet $45

3/4″ CDX 4×8 38.40

2x4x8- they sell this by foot in 16 foot lengths 52cents per foot.

1×3 pine clear 68cents per foot

3/4×3 1/2 Flexible stock – $8 per foot

Oak Board- 3/4×5 1/2″ $2.75 per foot

Oak Board- 3/4×91/4″ $4.75 per foot

Oak Board- $1×4 1.85

Group: Shara Sergio Laura

5/4×3 Pine 68 cents per foot

Wiggle Luan 3/8th 45$

1/4 Luan 4×8 16.64

3/4 plywood CDX $38.40

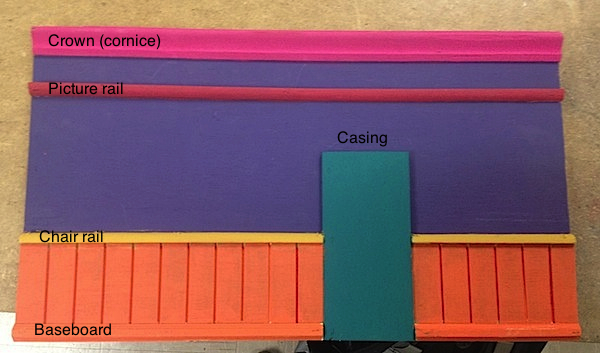

Molding Prices: the numbers can be referenced in Dykes Catalog

this is a link to the PDF:

http://www.dykeslumber.com/wp-content/themes/dykeslumber/Dykes%20Moulding%20Catalog%202012.pdf

****ALL PRICES ARE PER FOOT!!!!!

282- 86cents

293- $1.75

555- $3,60

144- poplar $1.10

93- pop $0.80

94- pop $1.25

95- Pop $1.85

321- $0.60

82- $0.34

**If you want anything is flex mold add $5.00 to that price per foot.**

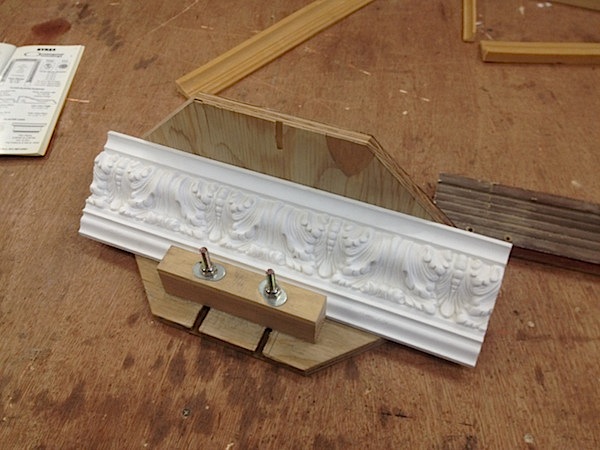

So the 555 Base Cap molding that John specked in the section view is actually oak. You would not order this unless you are planning to stain the wood. Peter, the nice man on the phone, gave me a price for Prime pine at $1.85 and MDF $1.20 per foot. So this is what you would want unless you are staining wood. Lumber comes in different lengths 8 16 24 but is sold by the foot and you need to specify the length you want when you order it.

If you want anything in Flex you need to plan at least 3 weeks in advanced. Dykes has to send away for it and then get it, then custom make it for you, so it takes time. so if you plan on doing a lot of flex then plan 3 or 4 weeks in advanced to place the order then build time and it is expensive.

John asked me to add a few things I learned during this time. I learned that when your calling a company you have to know exactly what you want and how much you want of it and grade that you want, or they will get frustrated. Rosebrand doesn’t get as frustrated as Dykes though… Anyway I also learned I need to think of the bigger picture not only the small details, for example how is the molding going to attach to the wall unit if I have all this foam inside rather than a solid molding. Try asking for prices not a quote of the material you need so someone doesn’t go to that effort to make the quote when your not buying it. Just keep constant communication with your group always know how your building your project so you can discuss it with others, especially John. I am hoping to learn more during this project. Hope this estimate will help. If you have a question about anything you can comment on the post, text me or email me.