Follow up from Tuesday:

We started class by following up from the end of class on Tuesday when Mike suggested the use of drywall to create the walls of the set. John opened it up for class discussion.

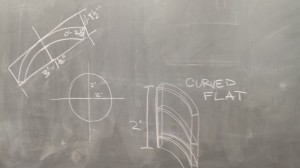

Metal studs and drywall→

Shannon: it will look like a real apartment but can you bolt?

John: has anyone worked with it?

Metal studs are lighter then wood but drywall is heaver

In construction the instalation of top and bottom rails lock in the stud

Without ceiling to attach top rail to what makes wall secure??

Looks like drywall, bc it is drywall

To make lauan look like drywall you need to coat w joint compound

F2M: Plot Discussion

What were good points?

- Clarence (father) asking about hormones

- Lucy knowing who Parker really is ( famous and a man)

Where were you bored?

- Repetitive- Was the author out of things to say?, intentional it has been repeating for Parker’s whole life

- Lost steam in the argument by the end of the play

Parker → inner conflict and outer conflict

Play could have ended one scene earlier

- End with Parker saying “this is who I am”

- Not needing to know the Lucy and Parker are ok

Conflict doesn’t need to be resolved for the play to be effective

John: How does the class read plays?

Shannon: making sure you read the play seeing the actions where they interact with objects → More a design concern?

Sergio: emotion for slamming doors, and reactions in the space

Laura: they use the kitchen→ “do you want some toast”, Does it have to be real?

Sarah: transitions from location to location, quickly!→ Script doesn’t tell you how to treat the transitions, written like authors background TV

Budgeting Discussion

How do you use the script to decide what to keep/cut?

Look at how and how frequently it is used

Theoretical Props Budget Scenario

problem: Lot of money for photo printing → over budget

proposed solution: Cutting half the photos →is that a good cut??

discussion: No because the drive of a character is told through the photos, people in photos are told in script

problem: kitchen props are extensive and expensive

discussion:

- Cabinets → only one opened

- Fridge → can be dummy with a light, can make dummy freezer cold with ice

- Ice cream→ containers out, does it get served?

- Sink → glass of water

- Toaster→ toast made

- Stove→ hot plate in dummy stove

List of things to look for when reading a script as a TD

- You have to read it once

- Have drawings with you to refer

- How many locations / how many visits to each location

- Definite physical actions (slamming doors)

- Transitions

- How long, where are they going?

- What has to move in the transitions?

- Practicality of pieces / what is real?

- Sight-lines

- How does moving parts get operated

- Will need working fridge and freezer for props

- Backstage

- Egress

- Space for everything

- Where do things go when it isn’t onstage

- Interaction with other departments

- Every department will be on set

- Video → is there equipment that needs to be set mounted or rigged, cable management

- Sound → is there equipment that needs to be set mounted, holes in things, cable management (where speakers are needed but scenically pleasing)

- Costumes → can costumes fit through egresses, quick changes (on stage/ backstage)

- Stage Management → if there aren’t sight-lines to the stage, where are they calling from

- Props → tracking for storage, does anything need to be set mounted or floor mounted, is it a prop or a set piece?

- Fight Director→ how they interact with set does there need to be safety modifications

- Electrics→ is there equipment that needs to be set mounted, practicals, holes, who is taking care of the sink (is it electrics or set), outlets or switches, genie and ladder access and storage

- Show Control→ what is driving all set mounted electrics

- Scenic Arts → access, what materials are paint treatment what is real, maintenance

Next class 4/24 INITIAL BUDGET PRESENTATIONS and approval

Structure of presentation :

- Divide the set into units

- Set designer (use designer’s labels)

- Figure out HOW

- Sketching to show how you are approaching the build

- Test of materials or research

- Cost Per Unit

- Materials

- Labor