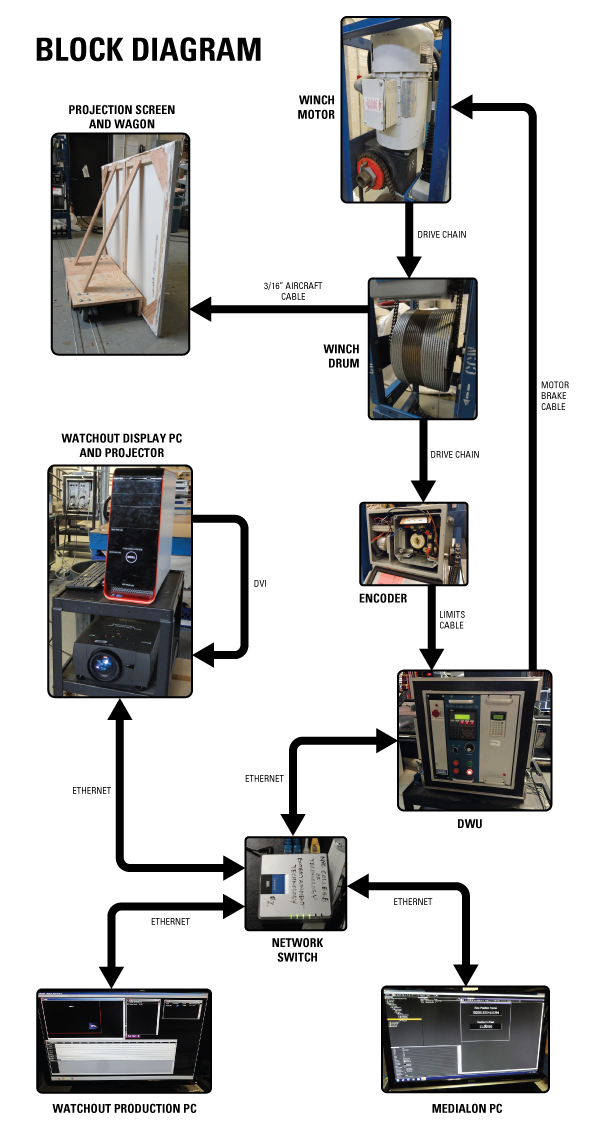

The projection screen is pulled back and forth by a loop of 3/16″ aircraft cable wound around the drum of a Hudson Scenic motorized winch. When the drum rotates to move the screen, it also turns an encoder linked to the drum via a drive chain.

As the encoder turns, it generates electric pulses, with a resolution of 1024 pulses per foot of travel. These pulses are transmitted via the limits cable to a PLC in the DWU (the winch’s digital motion controller). The PLC counts the incoming pulses and uses them to track how far and in which direction the winch drum turns, and by extension tracks the position of the projection screen.

The Medialon PC sends a continuous series of position request messages to the DWU via ethernet, and each time the DWU responds by sending back the current position value from its PLC. The message is sent in ASCII format, which Medialon converts into a real number representing the position in feet, down to three decimal places. Medialon then passes this value over ethernet to the Watchout Production PC.

The projector is positioned so that the left and right edges of its projection field align with the extreme edges of the screen’s range of motion, a distance of 15 feet. The projector’s horizontal resolution is 1,366 pixels. Therefore, one pixel is approximately 0.011 feet wide. In Watchout Production, a motion tween formula is applied to the projected image. This formula divides the position in feet value coming in from the Medialon PC by 0.011. The result is the position in pixels within the projection field where the image should be in order to match to the physical position of the screen. As the screen moves, the projected image follows it.