The Process Of Letterpress Printing

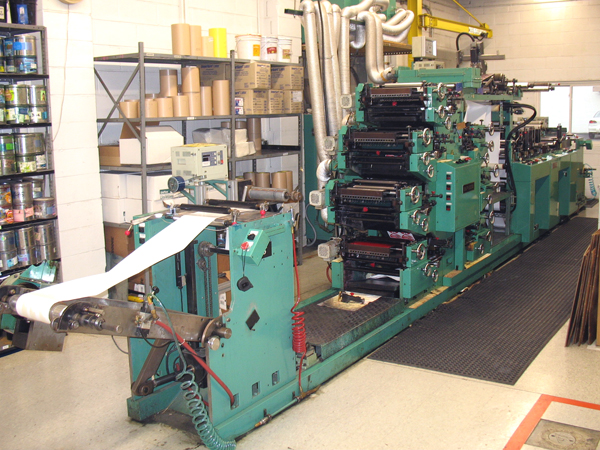

Rotary letterpress

The machine requires a curved printing plate. The Ink is fed and applied to the roller from the ink tray.The roller feeds ink into the secondary rollers that may apply ink directly on the printing plate. The paper is pressed against the print plate by another cylinder, referred to as the an impression cylinder and the ink is transferred to the printable surface. The Rotary presses can be either sheet- fed or have paper fed into a large roll called the web and can be referred to web printing.

Platen letterpress

Is often used for announcement, letterheads and forms. On the platen printing presses, the plate is fixed to a chase ( a type or frame) and is placed into the printed bed. The paper is placed in the platen, where the flat surface is opposite to the print bed. The ink is applied to the plate by rollers used. The ink is place to the substrate and then the process is completed.

Flatbed

Is a slow process and is rarely done in the United States. On the flatbed printing presses, the plate is affixed in the same manner on a platen press. The printing plate is inked by the roller and the cylinder pulls a sheet around it by the grippers that is on the cylinder. As the paper is pulled by the plate under the cylinder as the ink transfers the ink.