All pieces were made using MAZAK 250 Smart Turn CNC Lathe and Designed using Mastercam. Most of the pieces were randomly designed on the blackboard on the spot by the CLT. The randomness of the pieces were less for aesthetics but more for us to practice our ability to thread, face, groove, and rough our pieces.

Brass piece on MAZAK 250 Smart Turn. Face, Rough, Groove and Thread Features. The initial run was damaged by the second groove feature took effect; we reasoned because the first groove was closer to the spindle, the pressure from the groove tool was too much to support by the smaller diameter created.

Brass piece. Face, Rough, Groove and Thread features.

Created on Aluminum stock. Face, Groove, and Thread features.

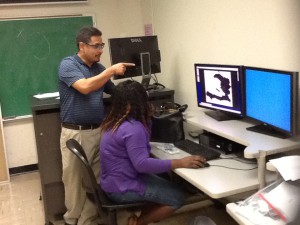

Dominic, one of the CLT’s at the Mech. Eng. Department and Rose, one of my fellow classmates. Dom was pivotal in helping us use the CNC lathe.