Since enrolling in CityTech I’ve discovered a love for 3D Printing. When I saw a YouTube clip of a multi-part wrench being assembled as an entire piece it baffled me. What was even more astonishing was how the technology had been around for thirty years. Obviously there are a lot of possibilities and although there isn’t one in every household, I don’t see how that couldn’t change in a decade or two. I remember growing up with computers and how at the time it wasn’t practical to own one unless you knew DOS. Obviously that’s not the case now, but as you get older you appreciate how technology evolves.

This video helps put things in perspective

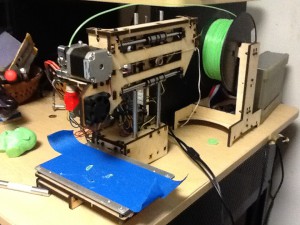

For me, it started with the Printrbot Simple model, which I purchased as a kit so I can see if 3D printing was for me. It was awesome to see how everything worked and Printrbot had for this particular model’s motors drove a braided fishing line wrapped around each motor’s spindle which created the the x,y, and z movement. It’s a little disappointing to see they use the belts now for the newer Simple models. You’d figure I would have purchased a Makerbot by now, but I’m enjoying working with lesser known brands. Aside from that, you don’t really learn much from Makerbot because you can’t really take things apart. I guess most of the fun is getting frustrated that something’s not working right. In the About Me page you can see what kind of machines I’ve been using.

Anyway, below are some pieces I printed for various purposes.

During the Spring semester of 2015 one of my classmates asked me to create a piece for his father’s Oldsmobile; this was a coupling used for the car’s automatic seat adjustment. The original piece was cracked and held together with scotch tape. I used this piece to measure with a caliper and created the piece with Solidworks. Obviously I used the 3 point arc to create the feature and the ‘keyhole’ was a pretty simple shape to make. Unfortunately I don’t have the Solidworks file anymore but I think I have the .stl file.

My 3-D printer from Printrbot. This was the Simple model which arrived as a kit. Below are some photos/video of some prints.

Some random head I pulled from Grabcad.

Click on the link below for a few seconds of the the printer in the final seconds of completing the print:

Gears designed on Inventor from Autodesk.

These gears, spacers, and converters were made for our Machine Design class. We were to design a gear box that would reduce the speed of our motor with a 2:1 ratio. The small “spacers” were created to hold both the hex shaft and round bearing together as a converter. The motor’s output had a star shape outlet so a converter was created from that shape to the hex shape.

Last month, I was commissioned to set up the 3D Printer that is part of the Business and Industry Training Center at CityTech. After everything was set up, I had to create some test prints. One was from the printer itself; I’m sure most 3D print aficionados are familiar with the default shark print on the Makerbot. I also printed a flower using a file someone shared on Makerbot’s Thingiverse . A gear was printed that was created using Solidworks. Someone from the office requested I make her a cake on the 3D printer. Granted, PLA is biodegradable, but it’s probably not recommended for consumption. All that it took were simple extrusions, some circular patterns, and a little star and candle effect were created. Unfortunately the tip of the flame of the candle was a little too sharp and thin and came off.

pinion and driven gear

pinion and driven gear