Through the SVA program I worked at the following Companies:

- littleBits (2016-2017); Product Design Intern

- Clarapath(2018); Mechatronics Intern

- Teknikio (2018-2019); Electronics Design Intern

- Boyce Technologies (2019-Current); Intern Manager & Engineering Intern

Some of the skills that I gained from my Industry experience include:

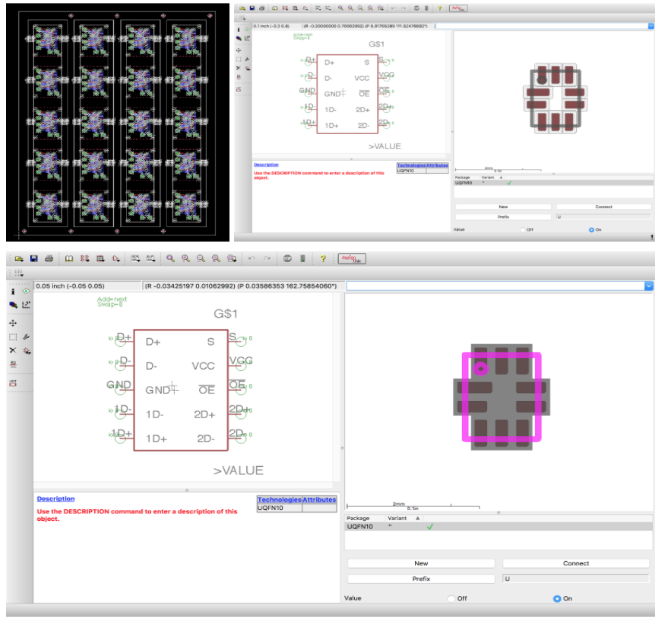

- I learned how to create printed circuit boards (pcbs) using Eagle

- I learned about the world of nano technology

- The product design cycle

- How to make tutorial videos

- How to user test

- How to solder under a microscope

- How to design, create, and frame a product

Here is a sample project that I worked on at littleBits:

Electrostatic Discharge Project- Completed on October 04, 2017

Overview:

ESD stands for electrostatic discharge and in my context, it simply means that the circuit is attacked by an abundant amount of voltage. At littleBits, products may be subject to ESD. One example can be a kid playing with littleBits on the carpet. They could be wearing socks and running around, like most ten years old do, and their socks eventually build up a layer of charge with the carpet. Then, when the child goes to pick up a bit they would experience a slight shock. That shock may destroy our components, leading to an unhappy child because their Bit doesn’t work now, leading to an unhappy parent ultimately losing some of the company’s credibility. So I began my long and forgoing quest. Throughout this process, I had to write up littleBits standard engineering reports using google sheets.

Problem and Solution:

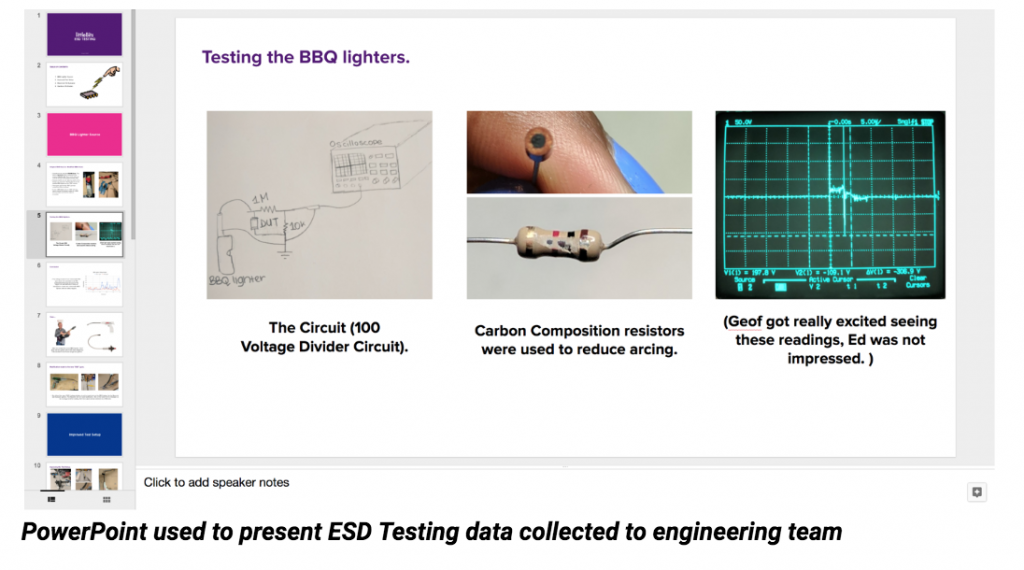

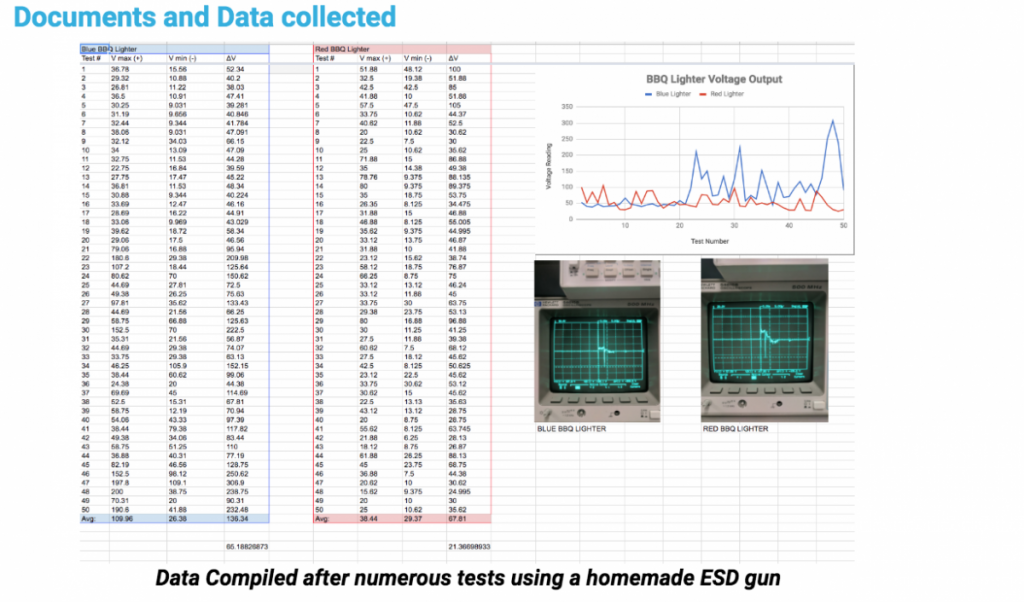

Often, the components that we have on our circuit board already have a level of ESD tolerance, however, based off of our consumer reviews we have determined that more protection is needed. So, we started testing ESD protection components side by side. In our current circuits, we are utilizing a TVS diode but the TVS diode is quite expensive when compared to the Varistor and we will be utilizing millions of them. For this setup, I placed the protection device in the voltage divider circuit. I tested each component twenty-five times and I determined based on data that the Varistor can replace the TVS diode. I put my findings in a PowerPoint and then presented it to the engineering department.

Importance:

For me, the most important part of the SVA program is the industry portion. The purpose of the industry is to not only provide SVAs with the knowledge they need in their classroom but to provide teachers with real-world examples that they can use in their essays.

In the program, we don’t get the opportunity to take classes within our field. The reason why is because we have to take a certain number of credits in order to get our teaching license. That credit amount is close to the amount needed for a bachelor’s degree, so many often opt to finish the degree. The industry is the only place provided by the program for us to learn our actual content area.

The accomplishments that I made in the industry is always utilized in the classroom. Especially when the knowledge that I gained was of why something does not work. Something I like to do in my class is blow up capacitors. You aren’t supposed to aim to blow stuff up in electronics but doing it in the industry and together as a collective allows students to remember and understand how and why something works the way that it does.