When the final impressions (taken using custom trays) have been received and used to make the final casts, it’s time to make the occlusal rims. In order for the dentist to take the bite (maxillomandibular relationship record) of an edentulous patient, occlusal rims are constructed of baseplate wax to simulate the occlusal surfaces of teeth.

The process of making occlusal rims starts with the fabrication of record bases. Aptly named, the record bases are the foundation on which the occlusal rims are built. The procedure is similar to that of making custom trays; since the occlusal rims will go into the patient’s mouth, all edges must be smoothed and rounded and all frenums relieved.

• • •

In Professor Cottone’s lab, we made our maxillary record bases of shellac and our mandibular bases of acrylic (methyl/methacrylate).

The shellac we used for our maxillary record bases is brittle and can only be manipulated when hot. It starts out as a small sheet that must be softened over a bunsen burner until it can be molded onto the cast without cracking. To trim the edges, an alcohol torch is used to selectively soften the excess shellac so it can be cut with a knife.

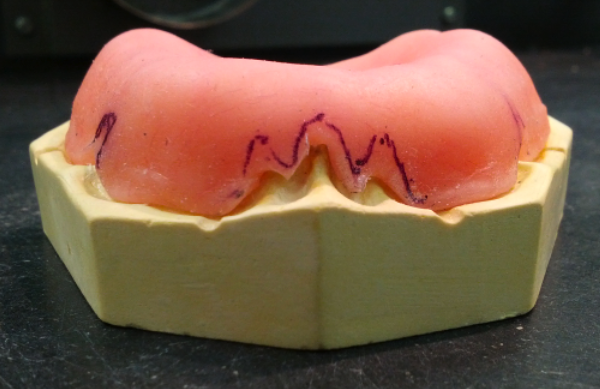

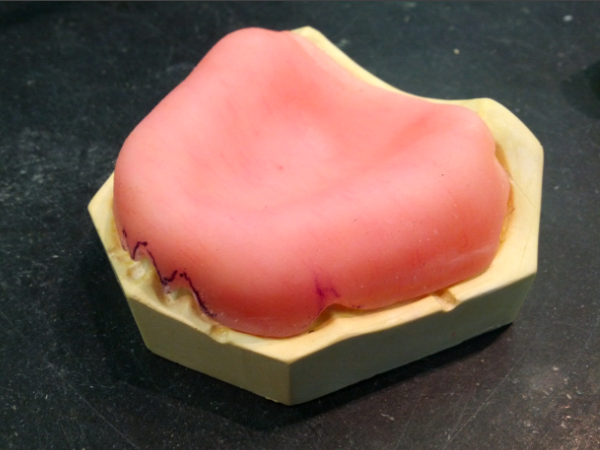

My maxillary record base (shellac).

We essentially followed the same procedure used for making our acrylic custom trays to make our mandibular record bases. The only difference was that the record bases required more finishing on the bench motor, as they must to be thin and needn’t be as durable as the trays. I may have gotten a little carried away with this step… I made mine so thin that it cracked when I started molding baseplate wax onto it! No big deal; it was easily mended with an extra dab of acrylic.

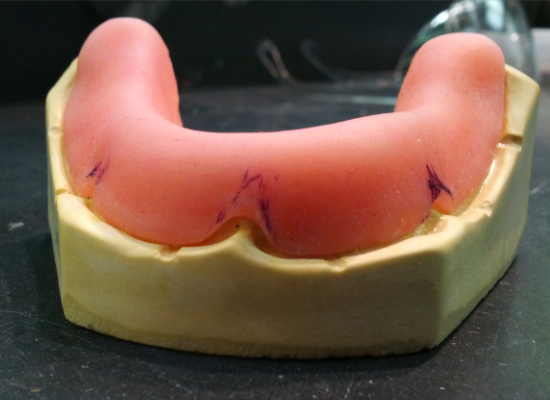

My mandibular record base, complete with repair patch (acrylic).

• • •

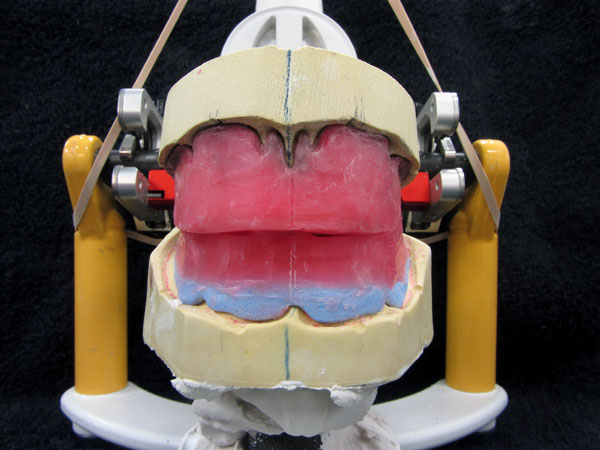

To make our occlusal rims we formed thick horseshoes of baseplate wax and sealed them onto our record bases, careful to center each over the residual ridge. Using a hot knife, we trimmed the wax U’s to the appropriate dimensions. Maxillary occlusal rims must be 22 mm tall at the anterior of the arch, tapering to 18 mm at the posterior; mandibular occlusal rims must me 18 mm tall all the way around. All measurements are taken from the deepest point of the labial / buccal sulcus. Finally, we smoothed our occlusal rims with a hot spatula and marked the median line on each.

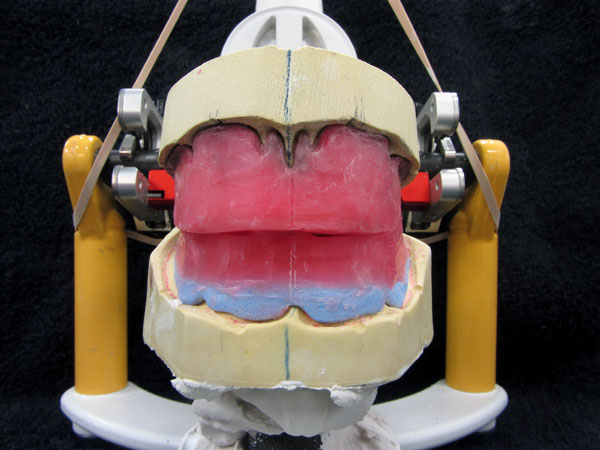

My occlusal rims, partially mounted on the articulator.