The vineyard that I went to was Martha Clara Vineyard, which is located in 6025 Sound Ave, Riverhead. I went there with my friends and their parents.

This is me in front of the Martha Clara Vineyard sign.

Right when we enter building, I saw how beautiful the inside is. One side of the building is a gift shop area, whereas the other side is where they sell their wines. The gift shop reminded me of Autumn and it seems very homey.

This is the entrance of the building.

This is the gift shop side.

The gift shop is selling many items related to wine.

Books are displayed near the entrance door

One of the wine displayed in the gift shop

We explained to the worker that we emailed beforehand before visiting. One of the employee named Margaret decided to give us a little tour and told us the history behind this vineyard.

The people from left to right are Irene, me, Margaret, and Tiffany.

Margaret explained that Martha Clara Vineyard was first owned by the Entenmann’s family (the pastry company), who were planning to open the place for horses. However, they noticed the vines growing in their land so they changed it to a vineyard. The owner, Robert Entenmann decided to name the vineyard after his mother. Thus, this place was named Martha Clara Vineyard. Afterwards, they sold the place to the Rivero Gonzalez, a Mexican family.

As Margaret continued to guide us to the building, we saw a wine tasting area and an upstairs to where guests can taste their wine privately. It also cost money to do wine tasting.

Tasting counters and area

Tasting counter

A private wine tasting room that is upstairs

As we continued further in, we saw a dining room and an outdoor chilling area to drink wine.

A sign in front of the dining room

The dining room

Guests can chill outside with their wine

The back side of the building along with chairs and tables for guests to hang out in

When Margaret lead us outside, she provided us information about the vineyard. She mentioned that they have 200 acres in total, where 100 is used on the vineyard. She also mentioned the soil they grow their vines in is sandy loam. Since they are surrounded by water, the Peconic Bay and Atlantic Ocean keeps the temperature steady. According to their website, “temperatures in the area are controlled by seabreezes that aerate the vineyards” (Martha Clara Vineyards, 2015). They have a maritime climate. Their fall are warmer as well, which helps avoid frost in the winter. She warned us to not go near where the vines are. However, we can look at it in a far distance. When we asked her where the equipment or brewery is, she told us that it is 2 miles away in another location called Premium Wine Group.

*An interesting advice that Margaret gave us when we asked how she became successful is to not have a boyfriend because they will get in your way.

There are Peach trees and sunflower fields.

There is a stop sign to warn us to stay away from the vines.

This is a zoomed in picture of the grape vines.

After looking at the vines, we decided to go back into the building to purchase wine. Margaret told us that Long island wine prices are higher than other places. Although they are more expensive, my friend’s father still bought some bottles for the hell of it. As we looked at the wine, we saw awards and medal plates hanging on the bottles. This tells us that, their wines are good. There are also signs that listed the dryness of the wine to how sweet they are. The signs also listed if they are aged or fermented in oat barrels along with the percentage of the grape varieties.

This is the cashier counter

Wines that are stacked nicely to be sold. The 2015 Solstice Rose wine are 40% off.

Medals on the wine bottles

The sign tells if the wine is aged or fermented in an oat barrel along with the grape variety. The sweetness level is also shown.

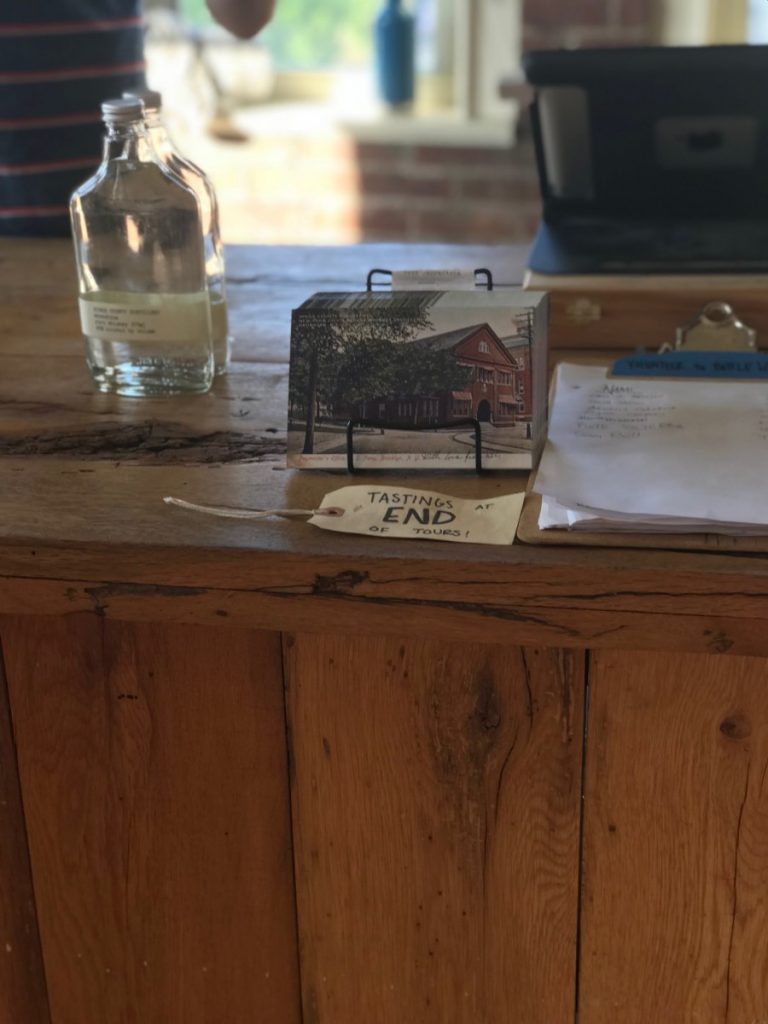

After leaving the vineyard, we went to visit the Premium Wine Group. Right when we arrived there, we only saw the tasting room. We asked an employee where the production and their equipment are. They told us that they do their productions and have their equipment in another location called Jamesport. We didn’t know where that is nor do we have enough time to go, so we left afterwards.

This is the Premium Wine Group building

Entrance to the tasting room

Inside the tasting room

Since we didn’t see any production facility nor find any equipment that was used to make their wine, I researched a bit about it. In the video, Fermentation – MCV Farm News Bulletin, Juan Micieli- Martinez, a winemaker stated that they have picked “Pinot Grigio, Gewurztraminer. Sauvignon Blanc, and Riesling” for their white wine and “Pinot Noir and Merlot for Rose” (Martha Clara Vineyards, 2017). He also mentioned that they do hand and machine picking and mixed them up, resulting “lower average brix levels” (Martha Clara Vineyards, 2017) for taste. He said that for white wine, they put the fruit in a “distend and put into the press. While in the press, the grapes are gently squeezed. The juice then falls into the press tray where it is collected into a receiving tank. The juice is then chilled and allowed to settle for a short period of time. The clean juice is transferred to another tank. Once transferred, heat is lightly applied to the tank to warm the juice to about 55 to 60 degrees. At this temperature the yeast is hydrated and then added to the tank” (Martha Clara Vineyards, 2017). According to the video, they use steel tanks and press trays as their equipment.

Juices are being pumped into the receiving tank. This is taken from the video, Fermentation – MCV Farm News Bulletin

This is the steel tanks taken from the video, Fermentation – MCV Farm News Bulletin

In another video called Red Grapes – MCV Farm News Bulletin, Juan Micieli- Martinez mentioned that “Cabernet Sauvignon and Petit Verdot, these two varietals takes the longest of time to ripen” (Martha Clara Vineyards, 2017). He also mentioned that red wines are harvested by hands and machines and are destemmed to tanks with their seeds and skins. The wine gets their tannin from the whole grape. After fermentation, they drain the tank and transfer the skin to the press. After pressing, they transfer the wine to a barrel and added bacteria for second fermentation. This softens their red wines.

The grapes are being pressed in the tank for red wine. This is taken from the video, Red Grapes – MCV Farm News Bulletin

Reference

Martha Clara Vineyards. (2015). ABOUT US. Retrieved from http://www.marthaclaravineyards.com/about.php

[Martha Clara Vineyards]. (2017, October 5, 2017). Fermentation – MCV Farm News Bulletin [Video File]. Retrieved from https://www.youtube.com/watch?v=AKNCQ4sRlas

[Martha Clara Vineyards]. (2017, October 19, 2017). Red Grapes – MCV Farm News Bulletin [Video File]. Retrieved from https://www.youtube.com/watch?v=3n_HiiMEwF8

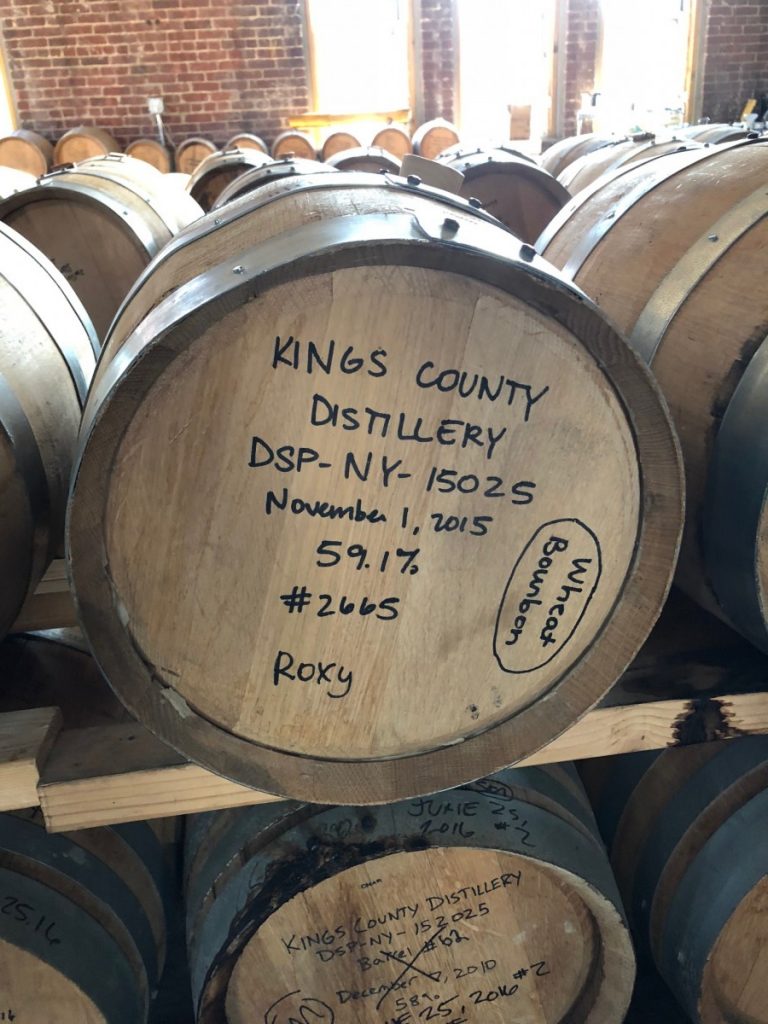

![The law in the United States requires that "straight whisky" (with the exception of corn whisky) must be stored for at least two years in new, charred oak containers.[2] Other forms of whisky aged in used barrels cannot be called "straight".](https://openlab.citytech.cuny.edu/goodladhmgt1101spring2018/files/2018/05/IMG_2420-1-e1526247046689-768x1024.jpg)