gina

https://openlab.citytech.cuny.edu/gsanabria-eportfolio/

Red Hook Wine Distillery

north forks and 10 to 15 percent come from the finger lakes. My follow-up question was “What was the reason for buying majority of the wine from the North Fork instead of the Finger Lakes?”. Secondly, “Why long Island and not any other region in the US?”. She stated that they wanted their wine to be unique, creative and specific, so instead of buying wine from all over the United State they stick with only Long Island vineyards. She also said that the North Forks have

Experiential Analysis @ VanBrunt Stillhouse – Nicholas Kandros

This past Saturday, May 19, I visited Vanbrunt Stillhouse located at 6 Bay St, Brooklyn, NY 11231. Vanbrunt Stillhouse has been since 2012 and is owned by Daric Schlesselman and Sarah Ludington. Daric is also in charge of most of the liquor production. Except for the saghi which is made by a worker named Bran.

Saghi is a Japanese spirit that is commonly made out of rice but can be made with other starches such as potatoes and even carrots. The rest of the alcoholic products are made by grains such as barley, rye and even corn. I participated in their 2pm tasting tour that was guided by Seth. Seth is fairly new in the industry with only 3 years of experience from working at Vanbrunt Stillhouse . The tour included four tastings of whiskey for $10. The whiskies that the distillery offers are American, Bourbon, Rye and Moonshine.

“Grassy, floral notes with the fresh oak sweetness of a bourbon & hints of tobacco.” – VanBrunt Stillhouse

“Bold and full bodied with notes of chocolate, butterscotch, sweet cream and banana, finishing smooth with hints of spice pepper, maple, nuts and coffee. ” VanBrunt Stillhouse

“Spicy on the palate with sweet floral nose, hints of coffee and chocolate, with raisins and cherries, and a lovely toasted almond finish.” – VanBrunt Stillhouse

Moonshine is unaged whiskey which explains it’s transparent color. Seth has explained very thoroughly step by step. He has mentioned that their barrels come from Indiana and Minnesota. The barrels are made out of American oak and are charred by the coopers. The char on the inside gives their whiskey a unique smokey texture and flavor as it ages. They have two sizes for the barrels. The smaller ones hold about 15-20 gallons of liquid and the larger ones hold about 25-30 gallons. At their facility, they prefer to use the smaller ones because they provide more air flow and age the whiskey faster than they would in the larger barrels. This has a very similar description to tawny Port wines. The first to make any alcohol beverage whether it is wine, beer or spirits is to prepare your grapes/grains. These ingredients have one important thing in common and that is their sugar source. In the case of spirits, corn, malt, rye, barley or other grain is used to produce alcohol thus giving you the final product.

They grind the grains into a flour then water is added to blend together. As the ingredients continue to mix this step is called mash. After mash, the paste is transferred to kettles where the fermentation takes place. At this point the alcohol is about 9% but rapidly goes up after the yeast has been added(“pitching the yeast”). Once the yeast has done its job, the ingredients are run through a grist hydrator that filters the alcohol.

This is a grist hydrator that distills the liquor(extracts the alcohol). When making whiskey, the liquid is usually ran through the machine twice to have a higher alcohol concentration. This process is what separates spirit making from beer making and is done after fermentation.

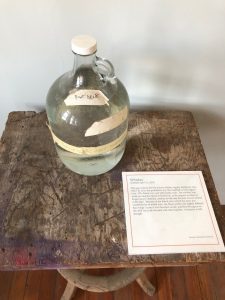

There are three parts known as head, heart, and tails. The head part is immediately removed since it is toxic which means it can’t be consumed. Afterwards, is the heart and the tails which are the parts we want for the final product. Both are very similar but tails are like a diluted version of the heart with less alcohol content. At this point, the alcohol is about 150 proof. Before bottling, it is diluted with water to bring down the alcohol. Moonshine would be immediately bottled since it is unaged whiskey. For the rest of the whiskey production, the aging process usually takes about 2-3 years. They sit the barrels on their sides and sometimes use the solera system to make blends. This is called “mingling the flavors”.

This is a smoker located outside of the facility in the back. It is not used on a daily basis but rather it is reserved for special whiskeys such as their smoked corn whiskey. Grains or corn are layered flat onto trays and are placed in the smoker. This provides additional smokiness to their whiskey.

Overall, my experience was educational. Originally, Vanbrunt did not have a tour open for 2pm because they were hosting a private event for Culinary Institute of America, which was cancelled with short notice. Luckily, since there was not a lot of time to fill up the time slot, it was only myself and two other people so I was able to ask plenty of questions.

References:

Flagship Brewery

I visited Flagship Brewery located at 3840 Minthorne Street on Staten Island. They are the first brewery to open on the island and the day I visited, it was their 4th anniversary. I always see Flagship when I am taking the train to the Staten Island Ferry, but I have never been inside. When I arrived I spoke to Mike, and he told me that the day I visited was 4 years that they have been open, then proceeded to show me the brewery. He has been with them since day one and said that he knows all the beers like the back of his hand.

Mike told me that their system is a 35 barrel system, which makes 70 kegs. In this machine, the mash, the mixture of water and malted grains, are combined. This then makes a wort, which is a hot sweet liquid. The wort is separated into two parts, the liquid and the grains. Here is where they add the hops, which provide flavor, aroma, and bitterness to the beer. At flagship they have some flavored beers for this summer which include their summer ale, key lime beer, jalapeño beer, and blood orange IPA. In the above picture, the kettle is connected to the Lauder Tun, the machine which separates the wort. The wort is then transferred through pipes which are on the ceiling to their appropriate tanks and this is where fermentation takes place.

Mike told me that their American ales are aged for 2 weeks and their Lager’s for 8 weeks. He said that Lager seems to be the staple beer at Flagship, and that their most popular Lager has the flavor and aroma of an ale, but the color of a lager, which I found interesting. At Flagship, their ales are kept in tanks at 65-70 degrees, and the lagers at 55 degrees. They use temperature control by using glycol which lines the tank and can change temperature through a computer system that they have. He explained glycol as an antifreeze which can manipulate the temperature of the beers.

Something that I did not know was that a keg is considered the large wooden kegs (barrels) which are lining the bar in the above picture. He told me that the tin kegs that they sell are considered 1/2 kegs because two of them can fit into the wooden keg. Their 1/2 kegs go anywhere from $150-200, and once you return the tin you get your deposit back.

At Flagship, they can make 60 cases of beer to a pallet and 8 kegs to a pallet. One 6 pack of beer costs around $12 and can be found a local delis and grocery stores. Mike told me that the same union that backs Budweiser, also backs them so that they are expanding where they sell their beers and they are also opening another location at the Staten Island Mall, but it will not be a brewery. Another beer that they have is one called a Sour beer. He said that they add lacto bacillus, which in turn flips the sugar in the beer to go sour and gives it a great flavor, without being overly sour. He explained it almost as a tang of a sour patch kid.

This was a very interesting experience and Mike’s enthusiasm made it even better. I was able to tell that he is very passionate about what he does and that he really loves his job. He said that they started with only 3 tanks and that they have a video on their website from when they first opened, which says where they hope to be in the future, and they are now at that point. Although I was unable to taste any beer because I am not 21, I learned a lot from this visit and enjoyed it very much.

New York Distillery Co.

I picked New York Distillery Company located on 79 richardson St. in Williamsburg Brooklyn, because i wanted to know more about how whiskey and gin are made.I have also never been to a distillery, and so everything was very new to me and my best friend. I participated in the VIP distillery tour and paid 30 dollars and it lasted about 45 minutes. What i liked about this tour was my very spunky tour guide Diane and also because they provided everyone with a mr. katz Rock-n- rye bottle and one cocktails of your choice at the bar. However, i also liked that they had water for everyone, magazines, stickers, and shirts.When we arrived at NY distillery it was 1:30 p.m. They weren’t opened yet when we walked in, was told they do tours 1 hour before the place actually opens to the public. The bartender said hello and we went straight into the area where the tour was being held.

Distilleries are dated back to the 1700’s and during prohibition there where about 50,000 illegal stills in NY. Until now there was an absence of distilleries in New York. New York distillery is one of the nations premiere craft distilleries. Founded by Tom potter co-founder of Brooklyn brewery and Allen katz an expert on distilled spirits and cocktails. The distillery is 7 years young, opened on December 5th (prohibitions anniversary). even if its young, it is amongst the oldest distilleries.

We tried 3 different gins each representing a different style and a different time in history. Gin has developed into different styles because it’s so loose and its an older recipe. This distillery primarily makes gin because it takes much less time, whiskey takes about 3 years inside the wood barrels to age, and primarily for color and gets its flavor from Juniper berries and barrels.

They use things that haven’t been used before in gin. I learned that in the 1600’s in the Netherlands gin was genever. Genever in the Netherlands, gin in England. To separate themselves from others the distillery asked themselves how they can put a modern spin on there gins and whiskeys. what if they used, and played with cucumber and rose, hibiscus, floral gins, and honey what would they get. very playful huh.

Diane our tour guide, calls these 3 gins, Time travel through gin because each was inspired by a time in history. Gin- number one- inspired by Dorothy parker who was a writer in the 20th century. Dorothy loved her cocktails and her gins.so they added juniper and elderberries, citrus, cinnamon, and hibiscus to the Dorothy parker gin.

Gin Number two- perks tot a British inspired gin in the 19th century. inspiration English origin

Gin three- Chief Gowanus 17-18th century Dutch inspired style gin. made with grains, un-aged twice distilled rye whiskey, out into a pot with juniper and hops, distilled one more time then aged 3 months in a oak barrel.

The tour guide Diane was very nice she taught us how to taste the gin and the whiskey. She advised us not to shoot it straight, because you cannot Taste anything, if you do that you won’t be able to appreciate it. “Take your time she said”, First I had to take the gin into my mouth, first with the tongue, than slowly switching it around the mouth. Then swallow and flap your lips together to taste all the after goodness. Let me tell you, i took it like a champ. the first gin tasted of flowers and it was smooth.

How whiskey and gin is made at NYDC.

one: fermentation to make alcohol. they use yeast + sugar >>>alcohol + CO2+ heat

two: Distillation to concentrate the alcohol.In the pot it is the fermented mash goes in and it is heated. alcohol vapor goes to the column and leaves behind water, and solids behind. the column turns the vapor into liquid into the condenser.

Grain, water, heat equals 75% rye, 13% corn and 12% malt add yeast. After several days fermented mash is 5 percent A.B.V.

for gin: they re-distilled the base with juniper and for the whiskey they put rye and distillate into the barrels and wait 3 years.

I found it really cool that not only do they sale there house made liquor to companies but they bottle everything in-house and also hand label them. Guess who does that too, our tour guide Diane. “yes it is a lot of work, but its worth it” she said.

Experiential learning analysis

Gallery

This gallery contains 6 photos.

For my beverage production experimental learning analysis assignment I choose to visit the Kings County Distillery. The Kings County Distillery is located at 299 Sands street Brooklyn, NY at the Brooklyn Navy Yard building 121. Although The Kings Count Distillery … Continue reading

Kings County Distillery PB

On my visit to Kings County Distillery, I learned that it is New York City’s oldest operating whiskey distillery, the first since prohibition. Bourbon, Moonshine, and Whiskey are the spirits handmade at Kings County Distillery. What started as a small operation in a 325 square-foot room in East Williamsburg, Became an award-winning distillery.

King County Distillery uses Corn, Barley, and other grains straight from New York farms. King County Distillery is also very sustainable, the by product of the remain grains used to make the whiskey are used again and converted into feed or used for compost.

At the Kings County Distillery the Process of making their award winning Whiskey, Bourbon, and Moonshine starts by Malting the desired grain. (Corn, Barley) Which is the process of soaking the preferred grain for 2-3 days in warm water. This allows for the starch in the grains to be converted into soluble sugars to make alcohol. As the grains are dried in a kiln to stop any germination the Mashing process is started.The ground down grain used, which is called Grist, is now added to warm water to begin the extraction of the soluble sugars.The liquid combination of malt and water is called the ‘mash’. It is put into a large vessel called a mash tun and stirred for several hours. During this process the sugars in the mash dissolve to the bottom of the container used which a wooden tun. This process is normally carried out three times with the water temperature being increased each time to extract the maximum amount of sugar. The resulting liquid is called Wort. Any residue, such as husks, is called Draff. This is collected and used in the production of farm feed.

Fermentation begins once the Wort is cooled and passed into large tanks called wash backs. In The Kings County Distillery they use wooden Fermenters that hold about 440 gallons.

Here the yeast is added and the fermentation begins. The yeast turns the sugars that are present into alcohol. The distillers at Kings County carefully select the strain of yeast that they use because its can effect the final flavor they are trying to achieve in their spirit. The fermentation takes around 48 hours but at Kings County it may be fermented longer depending on what type of flavors and characteristics they are trying to bring out in their spirits.The Liquid at this stage is called the Wash because it is low on alcohol strength.

In the Distillation process King County distillers use copper still pictured above because copper is the best material for extracting impurities from the spirit. Taller stills with longer necks will give finer, lighter spirits. Stills work in pairs the wash enters the larger wash still and is heated the liquid vaporizes and rises up the still until it reaches the neck, where it condenses. This liquid is called Low Wines because it is unusable so it is passed through the second smaller still, called the spirit still. Three alcohols come out of this process Foreshots are very high in alcohol level and very pungent.

Feints are weak but also pungent. And It is only the alcohol from the middle or Heart of the distillation that is used and this is skillfully removed by a King County distillers and collected through the spirit safe. The Foreshots and Feints are collected and re-distilled with the next batch of Low Wines. The Heart is the spirit taken to be matured in charred oak barrels that will eventually turn into whiskey. Or put in glass jars if Moonshine was the goal of the end product.

The Maturation process for whiskey in the United States to be considered actual whiskey is spending two years in a newly charred oak barrel or cask pictured above. In Kings County the distillers have barrels or casks with their names on it so they could known it is the batch they personally worked on.

Some of the smaller barrels have been sitting 1-2 years already. The bigger barrels have been aging for 7 plus years. And are considered to be Kings County Premium Whiskey.

I enjoyed my tour of the Kings County Distillery I learned some history as well. About the Brooklyn Whiskey Wars of the 1860s which was fought just steps from the distillery. My tour guide seemed very passionate about the history of whiskey and the history the Kings County Distillery has created since its first batch of legal Moonshine. My guide as well had a profound knowledge of the process of making their well known Whiskeys,Bourbons, and Moonshines. My guide expressed throughout the tour that whiskey is a required taste and to keep an open mind in tasting. The guide had knowledge of the taste characteristics of the whiskeys, bourbons, and moonshines at Kings County. And expressed their favorite combinations or cocktails to taste with their spirits. Very knowledgeable on whiskey period. Although i was not able to taste the spirits due to my age I will be back in November to have me a taste.

Martha Clara Vineyard

On May 5th, 2018, I went to Martha Clara Vineyard with a group of friends and 2 parents. Prior to our visit, we called and emailed to let them know who we were and why we were there. Martha Clara Vineyard is located at 6025 Sound Avenue, Riverhead, NY 11901. Knowing it will take hours to arrive, we departed early and arrived at the vineyard at 11 am; exactly when they’re open.

This vineyard has a spacious parking lot and an old ranch-styled building. Past the entrance is a gift shop with some customers looking around and a few employees working. Once we entered, we told one of the employees that we sent an email having a tour in the vineyard. She left and a few minutes later, another employee said she’ll like to check the email because she wasn’t told about us; her name is Margaret. After confirming with the email and our identity, we proceeded into the building and into the vineyard.

The gift shop was beautiful. It has plethora of decorated or designed wine glasses used for gifting. There are also some crackers available for purchasing when you want to do wine tastings on the inside.

Once you get past the gift shop, there’s a huge area with two long wine counters with employees behind it. It looked especially spacious since there’s not much customers in the morning. Continuing on to the inside, there’s a private tasting room up the stairs.

Afterward, Margaret guided us to the public wine tasting room; it looked amazing. However, if you want table service, you need to get a reservation first.

After we were done touring the building, Margaret told us about the history of the vineyard.The Martha Clara Vineyards property stretches out to 200 acres and 100 acres are all vineyards. There are approximately 14 different varietals grown in this vineyard. Across from the outside tasting area, there’s sunflower fields but it’s still too cold for them. The climate for this area is Maritime because the vineyard is surrounded by the Long Island Sound and in the north and the Peconic Bay. Summer is cool and winter is warm. The warmth during fall helps reduce the frost in the winter. Other vineyards further in the Nassau County is warmer so they have the oak and maple blooming. At this point, the manager, Gina, came out to greet us.

There’s about 60 vineyards in the entire Northfork area and it’s been 30 years since the opening of Martha Clara Vineyard. This vineyard was originally owned by the Entenmenn’s family; the manufacturing company known for their pastries and other baked goods. He originally came here to raise some horses but there were vines already growing here so he opened up Martha Clara Vineyard. The name Martha Clara is actually the name of Entemenn’s mother. This vineyard has been operating nicely by the Entemenn’s but, they sold the vineyard to Rivero Gonzales after Entenmenn died last year. This vineyard continued to operate under his ownership and this wasn’t a problem because Mr. Gonzales had some vineyards back in Mexico so he had some experiences running this business. According to Margaret, they brew wine at a place called Premium Wine Group which 2 miles down the road. We asked her, among the 14 different grape varietals, which wine does she prefer? Margaret said it’s different for her everyday but right now she would like to have some Cabernet Sauvignon with some steak. When we asked if someone can take us into where the vines are, unfortunately, there’s no one available to actually guide us into where the vines are so we only walked around it and took some pictures.

We were unable to go past a certain point so we zoomed in the camera to take pictures. Even from afar, we can tell that none of the vines have buds yet; only able to see their cordons. I forgot to ask whether they graft the vitis vinifera onto the vitis lubrusca. Afterward, we went back to the giftshop to take a look at the wines again and did some shopping.

We drove 2 miles down the road and found the brewery, until we discovered that this wasn’t the production facility. This building was smaller than the other one and it only has a tasting room. I asked the employee if we could get a look at the production area and the equipment. She told us the don’t brew wines there; they brew it at Jamesport. This tasting room is small but they have seats and tables outside so I believe this tasting room is where people reserve for different events because there was a DJ outside near the parking lot. Unfortunately, we didn’t get to go visit the brewery at Jamesport because there wasn’t enough time.

Overall, I wouldn’t call this a bad experience because i want to go back after it gets warmer. All the employees here are knowledgeable about the wines and vineyards and has great customer service skills. The shop here has a plethora of wines so i will purchase it after I am over 21.

Reference:

JOIN THE FAMILY. (n.d.). Retrieved from: https://www.marthaclaravineyards.com/