On April 26th, 2015, I completed the construction of the Ukelora. It still needs some sanding and maybe a wood stain but I am very pleased with the results. The instrument sounds like a Kora in the higher registers and sounds like a harp in the lower. I like the mellow plucking timbre it has acoustically. While I was practicing, my sister told me it was very calming as she wrote her essay for grad school. However, I would like to test out different foot pedals to see if I can produce a more abstract sound from the instrument. I wanted to have tone and effect knobs built in at first, but I like this idea better because of the versatility and options it can give the musician playing.

There weren’t many problems I encountered when building the instrument. But there were things I noticed I could of done differently if I decide to build another one.

First would be when applying the goat skin. I secured it on before the neck was cut and most of the body was not assembled. This resulted in the wood warping due to the increased tension. It also made it difficult to attach the neck. I ended up just using clamps to make joints flush but it was a big pain in the tukhas just to line everything up correctly.

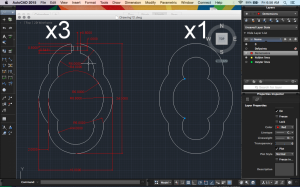

Second, would be the neck. To save on money and time. I decided to make the neck piece by gluing and stacking 4 cnc routed layers. Necks are usually made from one sold piece of wood and carved. When it came time to drill holes for the tuning pegs A LOT of splintering and splitting occured. I just applied a thick layer of titebond wood glue all over the piece, clamped it down and hoped for the best. It seemed to remedy the issue quite well.

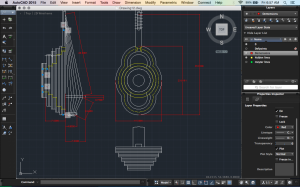

Below are some photos of the process and the completed instrument!