At the beginning of the class we learned a new knot called Double Fisherman’s Bend:

This knot is used for making high strength loops of rope. Once you tied this knot, it wouldn’t go through the pulley, so you have to be careful when determining where the knot is going.

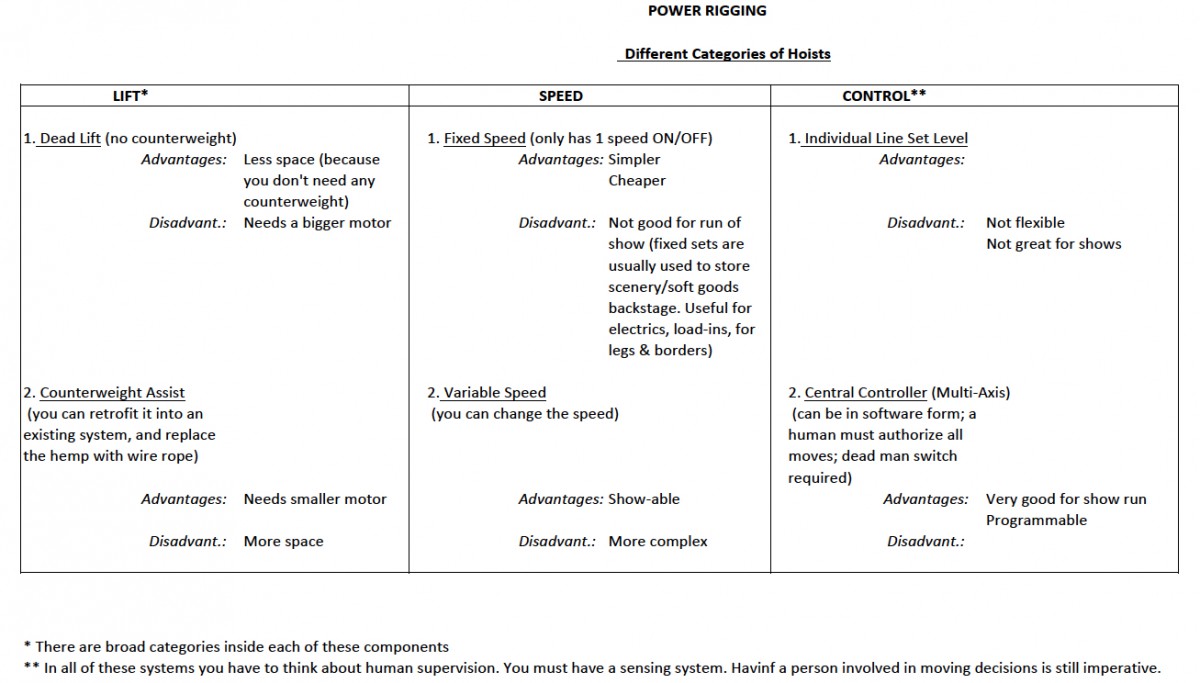

Next, a new topic,Power Rigging, was introduced.

After talking about control systems we moved to the Mechanical Elements overview. First, we watched a video showing an example of motorized Counterweight system – in this case, JR Clancy’s PowerAssist:

Very important point in this video was that it fits into the existing line set.

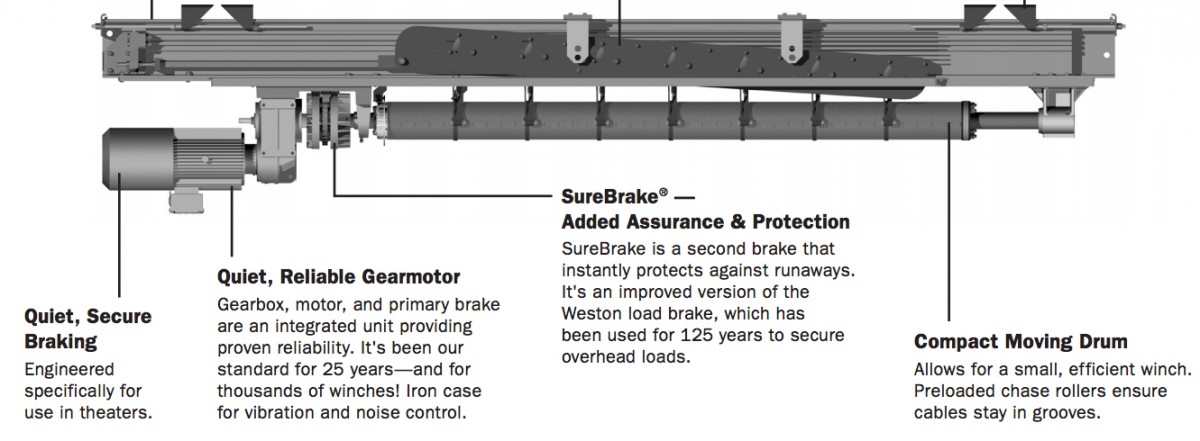

Next video was about a Dead Lift system – JR Clancy’s PowerLift:

https://www.youtube.com/watch?v=gfl1B2Bdw2c

PowerLift has a dual-brake system: motor side brake (smaller) and load side brake (larger and stronger):

The reason for having two brakes is that the gear reduced could fail. You always need a redundant brake on the load side.

Different Configurations of Parts:

- Point Hoist – single point that can lift something.

– It may have a Grooved Drum (the best for cable management, but the more cable you want to pull, the bigger drum you need).

– Smooth Drum (used essentially for boats; like tie-line on a spool). Disadvantages: the cable can crossover itself, or pile on one side of the drum.

– Pile-On-Drum (Yo-Yo Drum). The cable just piles up on top of itself. Advantages: skinny. Disadvantages: The diameter of a drum changes on the go. As the diameter changes, the speed of a drum changes as well; The load flattens out the cable.

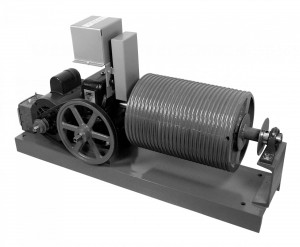

- Line Shaft Hoist:

Very simple as a machine: the motor turns all drums at the same time.

Very simple as a machine: the motor turns all drums at the same time.

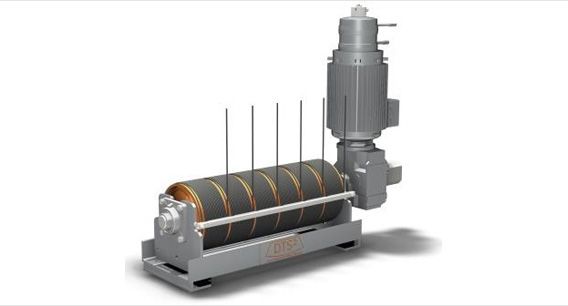

- Multiline Drum Hoist:

The machine is very compact; you only have to put pulleys.

The machine is very compact; you only have to put pulleys.

Line Shaft and Multiline Drum hoists actually reduce your load on the building (there is no counterweight load, only the load of the machine).

Safety Devices

Sensors:

Overtravel – knows where the batten is (height). You can program the range of positions.

Overspeed – used to detect if the load goes into the free fall. It’s not detecting the speed of the motor – only of the load. You also can program limits.

Overload – senses the overload being placed on the hoist and limits the machine from moving. The brake is strong enough to hold an overload, but it wouldn’t move.

Overcurrent – fuse or circuit braker.

Slack Cable Sensor – detects when one of the cables is underloaded, or looses tension.

Load Side Brakes – secures the load in case of gear motor failure.

_______________

Load Increase Factor – happens when you, or anything else is accelerating.

Range: 10% – 200% (always check with manufacturer of your device).

In order to find the maximum Dynamic Load:

LOAD x (1 + LIF) = DYNAMIC LOAD

Example: 1000# x 1.4 = 1400# Dynamic Load

At the end of lecture we watched two more videos – one on chain hoists:

Another one on pre-operational hoist inspection:

Then we moved to the shop and got an opportunity to operate chain hoists.

Key points from the lab:

1. There should always be only one thing on a hook.

2. Latch is not rated for any load.

3. Look for discoloration and other defect of the chain.

4. Listen to the sound of everything.

5. Choker hitch (for a spanset):

6. Every spanset has 3 ratings: Vertical, Choke, Basket.

6. Every spanset has 3 ratings: Vertical, Choke, Basket.

7. Spanset shouldn’t be crossing over itself.

8. Spanset tag shouldn’t be on the choke.

9. Never bump battens or trusses multiple times in a row: shaking waves could be in phase with each other, dramatically increasing the overall shaking of the system.

10. Clear communication is mandatory when operating any rigging system.