Introduction

We are in an age where we are questioning our ability to successfully work with society, nature, and the environment. In our environment, the impact of economic growth has created an imbalance in nature that is detrimental to society’s future existence. Existences where natural reserves are depleted, ecological resources are exhausted, and economic vitality is fictional. At the moment, the only way to ensure a viable future is to coexist with nature through developing and practicing operations that meet the current demands of people in society, and the needs of the future generation.

Method

To be able to plan out coexistence, we have to review industrialization as the major contributor. Industrial Revolution began through new manufacturing processes of going from hand production methods to machines in textiles.[i] Today, this idea of revolution through textile industry is still apparent in an emerging economy (e.g. India, Bangladesh, Vietnam, etc.)[ii] In these emerging countries, and the countries that started with textile industry revolution, the production of goods revolves around the using vast amount of fresh of water (According to UN Environment, the textile industry is the 2nd polluter of water in the world, accounting for 20 percent of global wastewater and 10 percent of global carbon emissions[iii]). To limit water waste and limit clean water contamination, we must look into approachable and practicable operational steps to take. The steps can be broken down into 5 types: recycling cotton, use sustainable farming, streamline production processes, dye clothes responsibly, limit our dependency on Fast-fashion, and begin to use Eco-friendly fibers[iv]

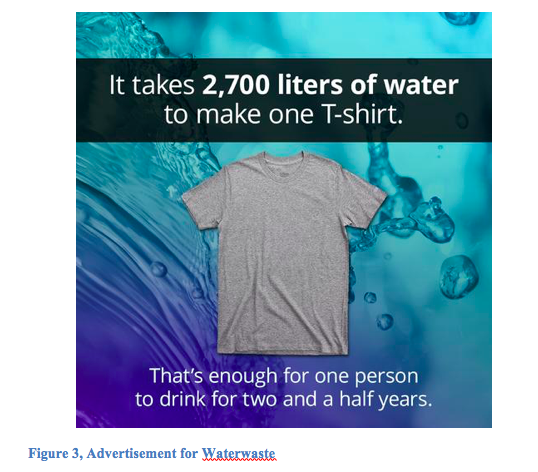

Recycling Cotton

According to World Wild Life, it takes 2,00 liters of water to produce a single cotton t-shirt[v]. And the world produces 29 million tons of cotton a year (That’s about 100 t-shirts per person[vi]): making it a very large drain of the world’s water supply. The best way to cut down on water usage is to lessen new cotton production and reuse already produced cotton through recycling. A method that is taking hold is an earth-friendly solution of collecting discarded material and breaking it down to create a new product for use. One such company is FabScrap located in New York City. The company collects unused scraps of fabrics and segregates it by different designations/categories to “utilize fiber-to-fiber technology”[vii] to create “insulation, carpet padding, furniture lining, moving blankets, etc.” [viii]

Sustainable Farming

We are in an economy where transparency trumps as one of the deciding factors for shopping. Because of that manufacturers are starting to become more aware of the negative impact a business might have depending on where it buys its supplies and how their suppliers produce the raw ingredients for end-use. The sourcing of the materials must come from farmers that apply an Earth-friendly process to cut down on water consumption. A consumption that far exceeds the reserve will be detrimental to the surrounding in ecological terms. An example of that is Cotton USA: 2/3 of the farmers use only rainwater to grow the crops. In essence, the carbon footprint is neutral, as “the plants remove more greenhouse gasses than production produces.”[ix] In the perfect world, the water use would be recycled to meet the many needs of a producer and farm, however, until we can find a viable recycling method, we have used natural methods.

Streamline Production Processes

For a garment to be fully completed, it goes through a process of trial and error, and through the process, it travels through many factories where fabrics are clipped/trimmed to fit the requirements of finished products. We have to look at the clippings as equitable to wasted water. In water, for the wastage to be minimized, the production has to be tested virtually through computerization. A computer program that has the ability to account for every square inch of fabric to every spool of thread that is needed to have a finished garment. However, rather than focusing on streamlining production due to sustainability, brands are motivated by business growth. Due to the nature of the current shopper’s habit of needed a product as soon as possible, brands are streamlining production to meet those timelines. For example, Gucci is bringing in producing in-house to control quality, craftsmanship, and timeliness away from small producers who are running family-owned-styled shops that are most of the time attributed to unsustainable actions.

Dye Clothes Responsibly

We have come far away from being forced to wear a garment in its natural form. We are no longer forced to limit our expression of personality with limited colors. We can afford to wear colors and shades through dyes that were once unimaginable, and that is usually done through synthetic dyes at a low financial cost. However, low prices have a bigger cost of polluted water resources with carcinogenic. Due to most synthetic dyes are petroleum and coal[x] byproducts and coming in liquid form; it is notorious for sipping into the water supply and rather difficult to filter. For us to control the spread, we have to limit the uses to natural dyes. One such brand is Anthemia: the designer primarily works with vintage fabrics and uses food scraps like avocado pits and onion skin to dye her fabrics.[xi]

Fast-Fashion Dependency

We as people are collectively failing to recognize the negative impact fast-fashion has. “One wash load of polyester clothes can release 700,000 micro-plastic fibers into the environment. Polyester, made from fossil fuels, is non-biodegradable.”[xii] Micro-plastic pollution is the outcome of microfiber dependency. The growing market of cheap-products is further contributing to this pollution. A great way to begin to eliminate the use of microfiber is through the use of cloth. Instead of using a simple absorbent cloth to clean dirt made out of microfiber, one uses their old t-shirt that is destined for the dumpster.[xiii]

Use of Eco-Friendly Fiber

If we must use fibers, we should use ones made in eco-friendly fabrics. Eco-friendly fabrics are made from fibers that force farmers not to use any pesticides or chemicals in the process of growing crops. The fibers are naturally resistant to mildew, mold, and is disease-free (examples: hemp, linen, bamboo, and ramie are eco-friendly fibers. … Bamboo breathes and wicks moisture away due to its porous nature[xiv]). Majority of clothes in the market are made from cotton and cotton farming requires a vast amount of pesticides used to ensure a healthy crop. By wearing eco-friendly clothes, a person is reducing the number of pesticides used daily as you are lowering the demand for clothing that is reliant on it.[xv] Pesticides are not only polluting that world but also our well being. Consuming pesticide in a large amount, a person can be poisoned or have long-term health issues like cancer.

Conclusion

Nature is mainly being polluted through the water. The only way to really limit our dependency on products that cause water-pollution is to share the knowledge. By saving money in the short term, we are paying the price of not having access to clean water. Without clean water, we run the risk of not being able to grow foods that sustain us. Additionally, our demand for cheap products is cutting corners to a point where we are further polluting our surroundings to point of no return. We have to view the world not as a commodity with inexhaustible resources, but as a space that we burrow for the future generation.

[i] David S. Landes (1969). The Unbound Prometheus. Press Syndicate of the University of Cambridge. ISBN 978-0-521-09418-4.

[ii] Lucas, Robert (2003). “The Industrial Revolution Past and Future“. Archived from the original on 27 November 2007. “[consider] annual growth rates of 2.4 percent for the first 60 years of the 20th century, of 1 percent for the entire 19th century, of one-third of 1 percent for the 18th century”

[iii] https://www.unenvironment.org/news-and-stories/story/putting-brakes-fast-fashion

[iv] https://www.stylewise-blog.com/blog//2017/11/4-ways-fashion-industry-can-reduce.html

[v] https://www.worldwildlife.org/stories/the-impact-of-a-cotton-t-shirt

[vi] https://www.theworldcounts.com/counters/cotton_environmental_impacts/world_cott on_production_statistics

[vii] https://fabscrap.org/about

[viii] https://fabscrap.org/about

[ix] https://cottonusa.org/sustainability

[x] https://www.mindbodygreen.com/articles/5-companies-dying-clothes-using-natural-plant-dyes

[xi] https://anthemia.co/pages/philosophy

[xii] https://www.theguardian.com/fashion/2019/jun/23/five-ways-fashion-damages-the-planet

[xiii] https://www.thekitchn.com/microfiber-cloth-alternatives-22937918

[xiv] https://www.telio.com/wp-content/uploads/2014/08/Organic-Fabrics-Info-Booklet.compressed.pdf

[xv] https://www.bizcatalyst360.com/10-benefits-of-eco-friendly-clothing/