Clamp coupling for 1/2″ to 5/8″ arrived. Proceeded to connect motor to wormgear.

Wormgear has 1/100 ratio.

Finished model for flying car the College Now students will have to build.

Clamp coupling for 1/2″ to 5/8″ arrived. Proceeded to connect motor to wormgear.

Wormgear has 1/100 ratio.

Finished model for flying car the College Now students will have to build.

Metal grate was removed previously

Removed motor from previous project

Attempted to attach motor to wormgear box

Proper coupling is required to connect wormgear to output of the motor; 5/8″ to 1/2″.

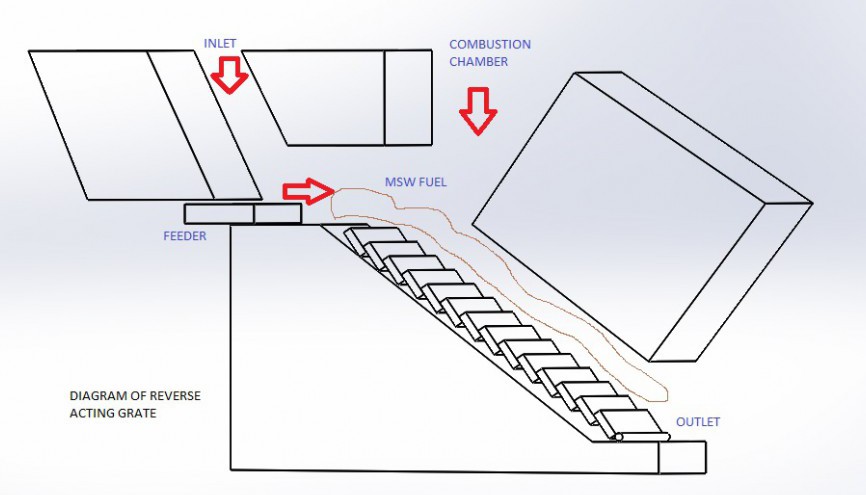

The motor is used to drive the wormgear to drive the arm that will somehow push the 2nd and 4th grate in our model. The first and third grates are stationary and the second and fourth grates move to sort the municipal solid waste (MSW). The steel members of the frame may be replaced in the future to make it more sturdier. Possible plans to incorporate microcontrollers

Coupling used to connect motor to wormgear. A new coupling clamp needs to be ordered to connect output of motor @1/2″ to input of wormgear @5/8″.

Attaching frame to grate

Attached grates to L-brace. Grates moved smoothly. Needs to be attached to worm gear in the future.

Start on Poster presentation

Reassembled frame, repositioned bolts and nuts

Grates can move smoothly now steel was cut and bent to allow clearance.

Attended orientation for College Now program

Discussed syllabus for students (Solidworks)

Cut frame of metal.

Continue work on screen

1) Conference Registration

2) Reservation of Bus trip

Work on Essay

Work on Screen

Worked on essay for scholarship. Continue with screen on Thursday

Received screen-

Discussion on how to attach screen and charge battery for tools

1008 Carbon Steel diamond grate

Plexiglass sheet

Testing which material to choose: plexiglass, steel mesh, or both.

Set up laboratory

Discussed schedule, poster presentation