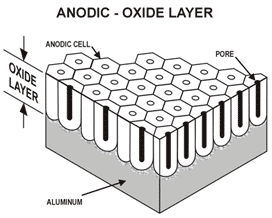

WHATS IS ANODIZING?

It is an electrochemical process that converts the metal surfaces into decorative, durable, corrosion- resistance, anodic oxide finish.

DRI DESIGN

SLOGAN :

“NO SEALANTS, GASKETS OR BUTYL TAPE IN THE PANEL JOINTS MEAN NO DIRTY STREAKS OR MAINTENANCE.”

Anodize Aluminum Panels:

Overview:

Successfully combines science and nature to create a great form of metal finish. The dense surface of the Aluminum is created utilizing the natural oxidation process and adding electricity and chemical to enhance the process and well as the outcome. This Aluminum process bring out the natural variation in colors which is expected.

PANEL INFO

Specification:

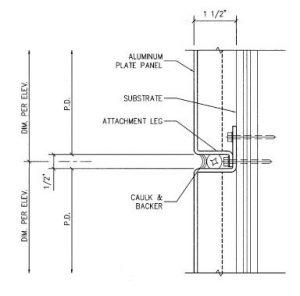

System Dimension: 1-1/4” Nominal

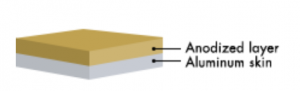

Material: Aluminum

Material Thickness: .08” standard (other gauges available)

Panel Joint: ½” Nominal Standard (1/8” to 1”)

Finish: Clear, Bronze, Champagne, and Black Anodizes

Weight: Less than 2 pounds per square foot

PRO:

- Exceptional abrasion Resistance, corrosion, chemical and solvents.

- Cost efficient

- Available in one-part or two-part panels.

- The anodize panel reveals the natural beauty of Aluminum while enhancing it strength and it aesthetic abilities.

CONS:

- Requires special processes to be welded.

- Prone to sever spring break.

- Abrasive to tooling.