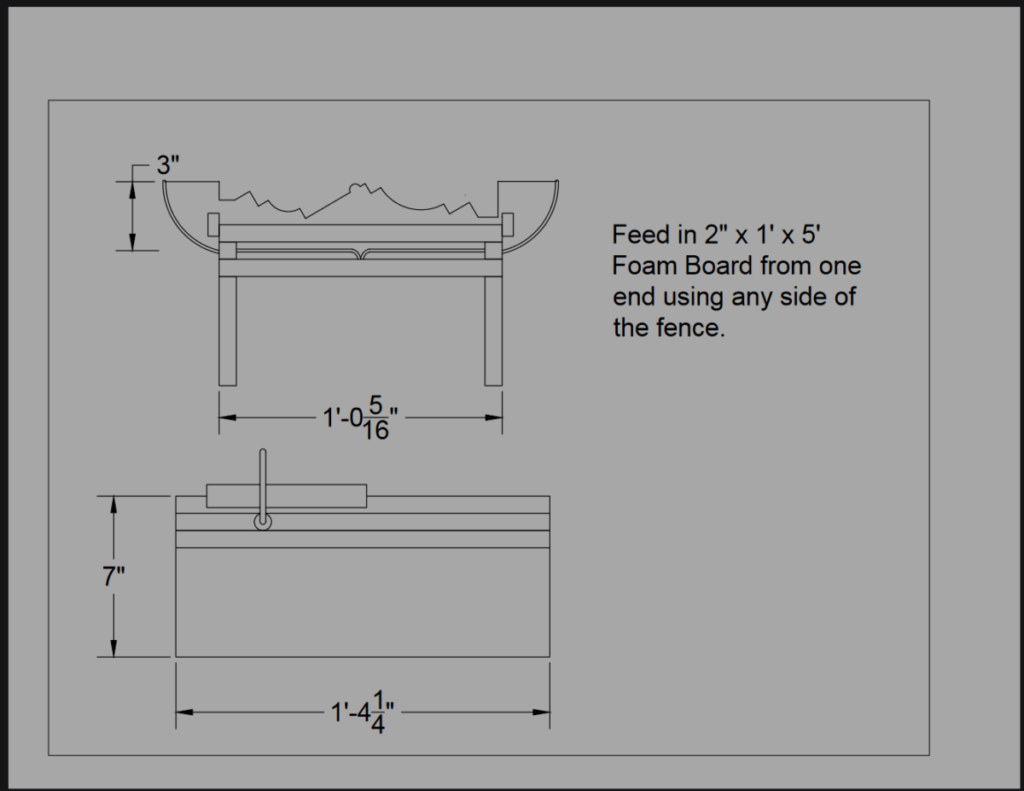

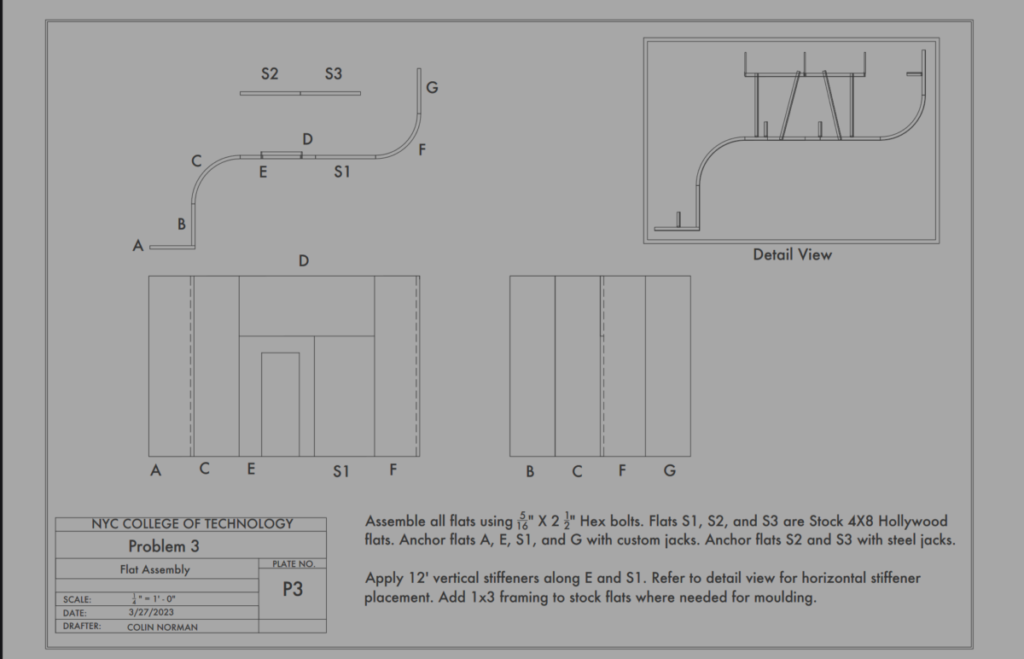

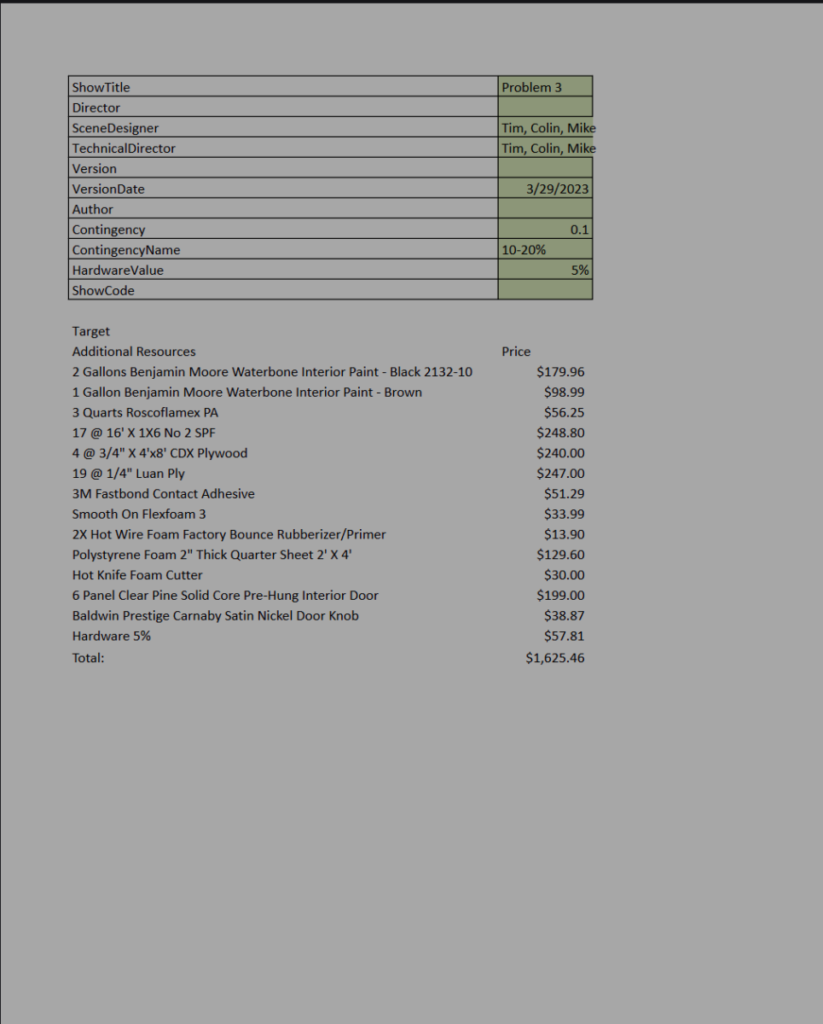

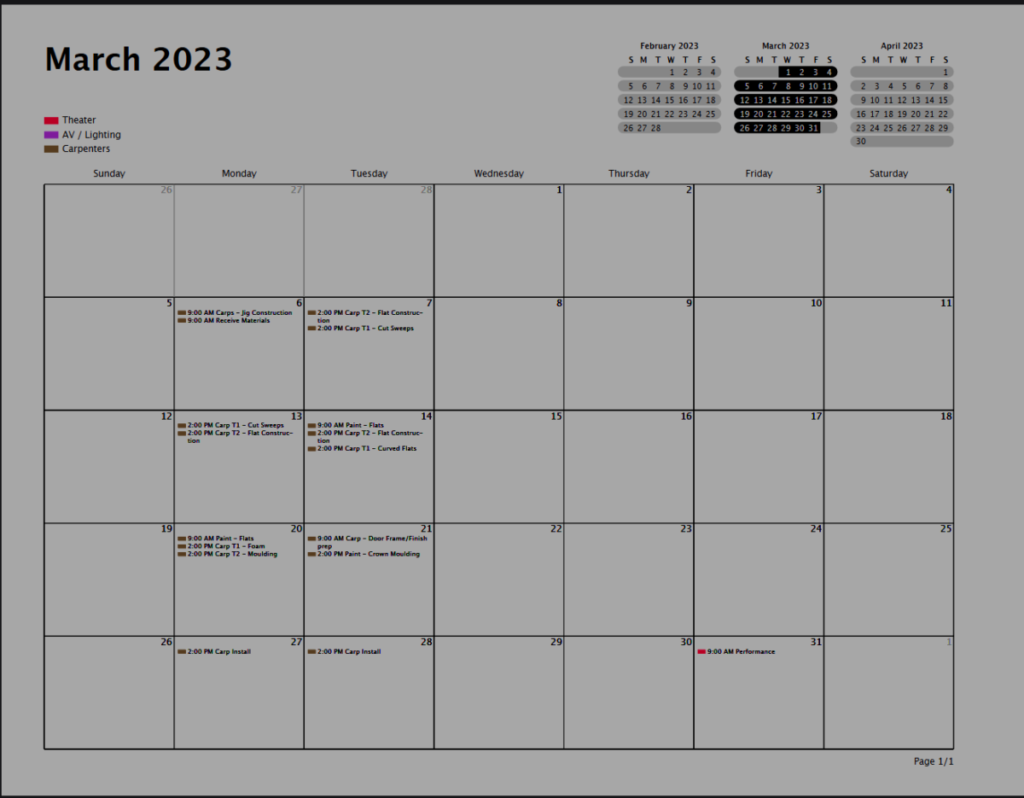

For Problem 3 Mike Colin and I were tasked with making this wall not shake at all when the door on the front was slammed. The door flat also could not have very large jacks for walking space and we could not put very much between the back wall and the flat. All of the set was also going to have this complex curved molding going all all around it. This problem was particularly hard for us because there was a lot going on, two separate issues compounded at the same time and none of us have experience building a curved flat or cutting complex shapes for molding. For the molding problem we had a two ideas. The first being we cut the shape of the crown molding once and then after shaping it out we use a machine to make a cast of the mold, then making the rest of the molding out of rubber. The other idea which we ended up going with was to make the molding out of foam and use a jig to cut the shapes using a hot knife. The jig idea worked out very well however the knife did break so we need to reiterate on our idea again. As for the wall we did one test where we slammed the door multiple times. It shook a lot on its own obviously so we needed to add reinforcement. First of all came the curved flat. We had never made a curved flat so we had to make a jig to get all of the angles right for the curve. Once all the framing members were assembled it took a bit top span the luan to fit the bend but it was got done. Along with the curved flat there was another 4×8 flat and the back wall that we had attached. With the two new flats we slammed the door again and it still shook. We attached jacks with sandbags and bracing to the top of all of the flats joining them together, and after slamming it again the wall did not move at all. Since this was about half the set we came to the conclusion that if we assemble the rest of the set with the same ratio of bracing, the set should keep the same level of rigidity. Regarding the calendar we had to work with multiple other teams and decide when was the most appropriate to build the set and such, so this was a challenge as well. Over all we gained a lot of technical skills such as making jigs, as well as working and communicating with other teams about load ins and coordinating schedules.