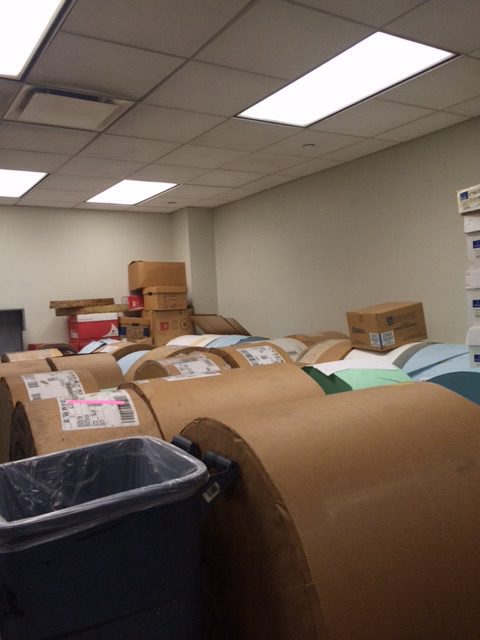

The field trip to the UTF print shop at 52 Broadway was very insightful. It allowed us to see the inner workings of a print shop that prints on a massive scale. The shop had printers for every job. They were capable of printing large objects like banners and high volume objects such as mailers and newsletters. Since the print shop has been around for a long time they had some old-fashion printers and some of the latest technology. The old fashion printer was similar to what you would see a newspaper printed on. It uses huge drums of paper and still had to be worked by hand by a man walking up and down on fatigue mats. We also got to see one of the more modern printers at work. It was this large scale printer with a external control panel and it was printing their latest mailer. It is capable of printing the thousands of copies that needed to be mailed. After that we were shown the area where it was less about printing and more about packaging. I learned that there is a machine that is capable of stapling papers together in a variety of ways. After papers are printed and stapled they have to be put into envelopes and mailed out. Were also able to see this process. This machine was all about gears and timing, it opens, fills, and seals only using and series of mechanical parts. The head of the print shop also showed us one of the newest printers he said it was the only one on the east coast. Things such as print quality and worker safety have improved greatly. Seeing all the printers in one place allowed us to see the gradual change in print technology.

© 2024 Malik Williams's ePortfolio

Theme by Anders Noren — Up ↑