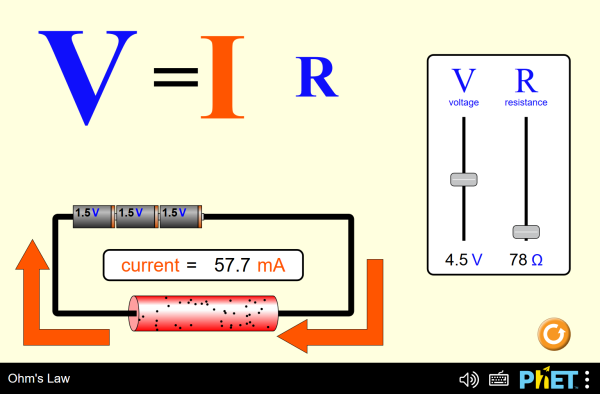

How to calculate the value of a resistor using the color coded stripes on the resistor?

Step 1) For the four-band scheme, the bands are always read from the end that has a band closest to it, which means to turn the resistor so that the gold or silver stripe is at the right end of the resistor.

Step 2) Look at the color of the first two stripes on the left end. These correspond to the first two digits of the resistor value. Use the table given below to determine the first two digits.

Step 3) Look at the third stripe from the left. This corresponds to a multiplication value. Find the value using the table below.

Step 4) Multiply the two digit number from step 2) by the number from step 3). This is the value of the resistor n ohms. The fourth stripe indicates the tolerance(=accuracy) of the resistor. For example, a gold stripe means the value of the resistor may vary by 5% from the value given by the stripes.

Resistor Color Codes (with gold or silver strip on right end)

Note: For the value of the resistors, the engineering notation should be used as shown below.

Engineering Notation

| Values |

Prefix |

Symbol |

| 1012 |

tera |

T |

| 109 |

giga |

G |

| 106 |

mega |

M |

| 103 |

kilo |

k |

| 10-3 |

milli |

m |

| 10-6 |

micro |

μ |

| 10-9 |

nano |

n |

| 10-12 |

pico |

p |

Example 1: You are given a resistor whose stripes are colored from left to right shown below. Find the resistor value.

brown, black, orange, gold.

Step 1) The gold stripe is on the right so go to Step 2).

Step 2) The first stripe is brown which has a value of 1. The second stripe is black which has a value of 0. Therefore the first two digits of the resistance value are 10.

Step 3) The third stripe is orange which means x 1,000.

Step 4) The value of the resistance is found as 10 x 1000 = 10,000 Ω = 10kΩ.

The gold stripe means the actual value of the resistor mar vary by 5% meaning the actual value will be somewhere between 9,500 Ω and 10,500 Ω.

Tags:

Inquiry/Analysis,

Breadth of knowledge