9-Jun Monday-Create Schedule and Introduction to renewable energy

10-Jun Tuesday-Check and order screen

16-Jun Monday-Setup laboratory. Prepare poster presentation

17-Jun Tuesday-Setup laboratory. Prepare poster presentation

19-Jun Thursday

24-Jun Tuesday-Installing screen

26-Jun Thursday

30-Jun Monday-Installing screen

1-July Tuesday- prepare poster presentation

7-July Monday-prepare poster presentation

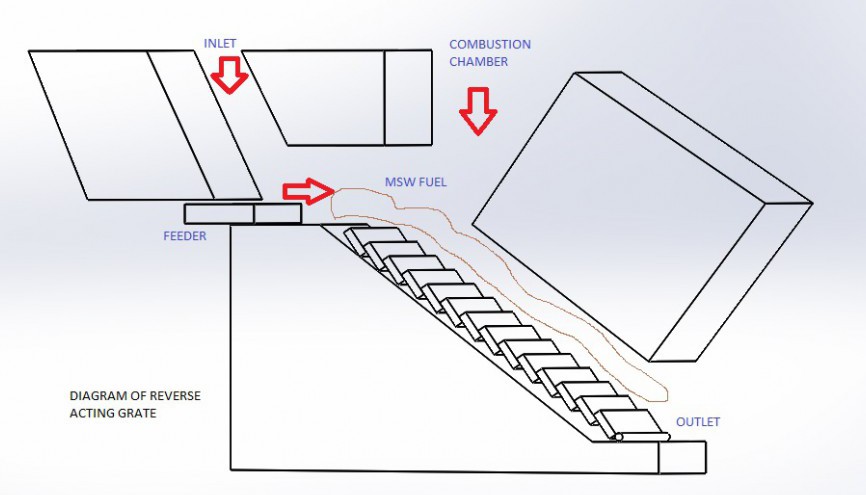

8-July Tuesday-prepare poster presentation, 3D model of combustion chamber

10-July Thursday-continue connecting motor to wormgear

July14-16: CLT work for Professor Nakamura for College Now program

July 17- Trip to Toyota Factory

July 19-20: Gordon Research Conference for Granular and Granular Flow

July 21,22,24: Continue work on physical model.